HCYY11112017 Towing And Lifting Cylinder For Agricultural Machinery

Kā viens no hidraulisko cilindru ražotājiem, piegādātājiem un eksportētājiem, mēs piedāvājam hidrauliskos cilindrus un daudzus citus produktus.

Lūdzu, sazinieties ar mums, lai saņemtu sīkāku informāciju.

Pasts:sales@hydraulic-cylinders.net

Hidraulisko cilindru ražotājs, piegādātājs, eksportētājs.

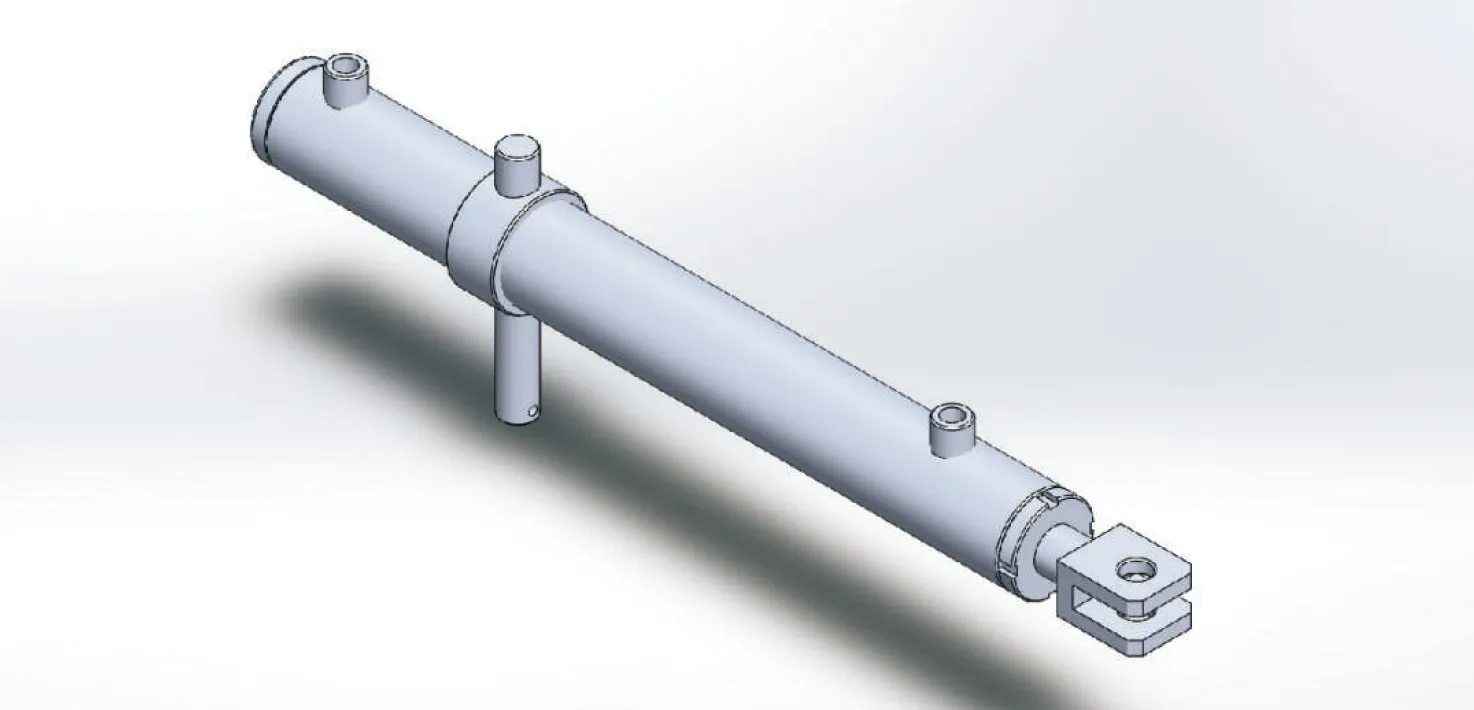

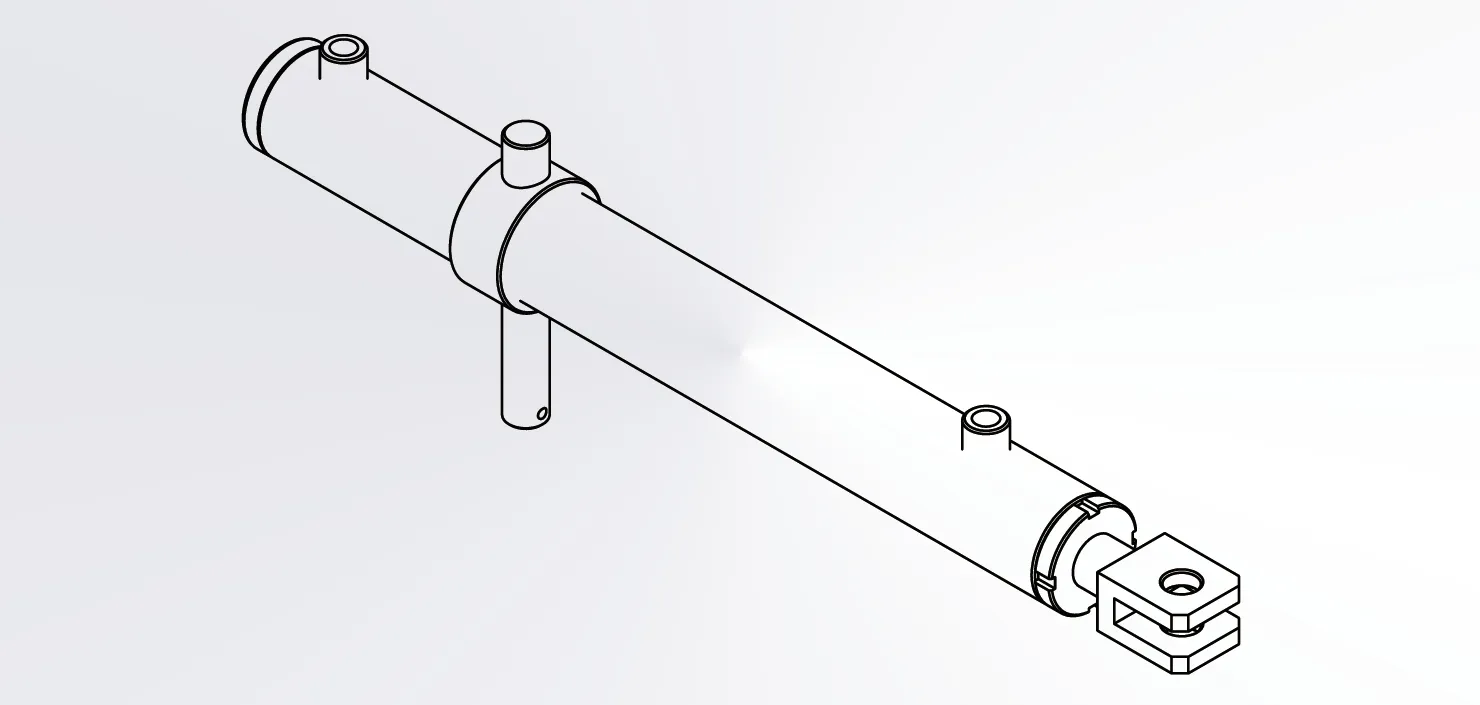

HCYY11112017 Towing And Lifting Cylinder For Agricultural Machinery

The HCYY11112017 Towing and Lifting Cylinder is a crucial component for agricultural and industrial applications, designed for exceptional performance in towing heavy loads and lifting equipment. Its versatility makes it an indispensable tool for professionals in the field.

This cylinder excels as a reliable and efficient solution for various towing and lifting tasks. With a high load capacity, durable construction, and compact design, it enhances any machinery fleet’s capabilities. By adhering to the recommended usage and maintenance guidelines, users can optimize the cylinder’s performance and extend its lifespan, ensuring maximum efficiency in operations.

Invest in the HCYY11112017 for a dependable solution that effectively meets all your towing and lifting requirements.

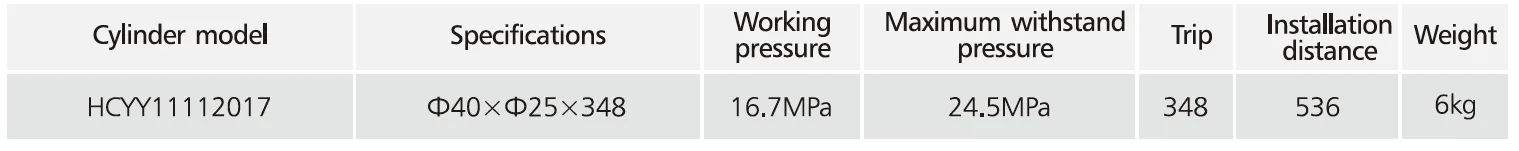

HCYY11112017 Towing And Lifting Cylinder Parameter:

Cylinder Series Of Crawler Crane:

Key Features of HCYY11112017 Towing And Lifting Cylinder:

The HCYY11112017 Towing and Lifting Cylinder boasts several key features that significantly enhance its functionality and appeal:

High Load Capacity

This cylinder is engineered to handle substantial weights effortlessly, making it ideal for heavy-duty applications. Its impressive load capacity ensures safe and efficient towing and lifting operations, allowing users to tackle demanding tasks without hesitation. Whether lifting large agricultural equipment or towing heavy trailers, this cylinder provides the strength needed to get the job done effectively.

Durable Construction

Constructed from high-strength materials, the HCYY11112017 is designed to resist wear and tear in even the most challenging environments. Its robust build safeguards against the rigors of daily use, ensuring long-lasting service life. This durability translates to fewer replacements and repairs, offering users peace of mind and saving costs in the long run.

Corrosion Resistance

The cylinder features advanced surface treatments that protect it against rust and corrosion. This critical attribute is particularly beneficial in agricultural and industrial settings where exposure to moisture and harsh chemicals is common. By extending the cylinder’s lifespan and maintaining reliability, this corrosion resistance ensures that the HCYY11112017 remains a trusted tool over time.

Compact Design

Its space-efficient structure allows for easy integration into existing machinery without compromising performance. This compact design is particularly advantageous for operations where space is limited, enabling users to maximize their equipment’s capabilities. The cylinder’s small footprint does not sacrifice power, making it a practical choice for diverse applications.

Precision Engineering

Manufactured with tight tolerances, the HCYY11112017 guarantees smooth operation and accurate load positioning. This precision engineering enhances overall performance, ensuring that loads are lifted and towed with exceptional control. Users can rely on this accuracy to achieve optimal results in their tasks, promoting efficiency and safety in operations.

In summary, the HCYY11112017 Towing and Lifting Cylinder combines high load capacity, durable construction, corrosion resistance, compact design, and precision engineering. These features not only enhance its functionality but also make it a reliable asset for any agricultural or industrial application, ensuring users can confidently tackle their toughest challenges.

How Does The Compact Design Of The HCYY11112017 Towing And Lifting Cylinder Improve Its Usability In Tight Spaces?

The compact design of the HCYY11112017 Towing and Lifting Cylinder significantly enhances its usability in tight spaces, offering several key advantages:

Space Efficiency

- Minimal Footprint: The cylinder’s smaller dimensions allow it to fit into confined areas where larger models would be impractical. This space efficiency maximizes the use of available real estate in machinery setups, making it an excellent choice for compact equipment.

Improved Maneuverability

- Agility in Operation: Its lightweight and compact structure facilitate easier movement and adjustments in narrow environments. Operators can navigate around obstacles with greater ease, allowing for more flexible operation in crowded or limited spaces.

Versatile Integration

- Seamless Compatibility: The HCYY11112017 is designed to integrate effortlessly with a variety of equipment. This versatility enables users to incorporate the cylinder into existing machinery setups without the need for extensive modifications, saving time and effort during installation.

Enhanced Stability

- Lower Center of Gravity: The compact design contributes to a lower center of gravity, which enhances stability during operation. This is particularly beneficial in tight or uneven terrains, reducing the risk of tipping and ensuring safer lifting and towing processes.

Simplified Operation

- Ease of Access: Operators can easily reach and operate the cylinder even in cramped working conditions. This accessibility promotes safety and efficiency, allowing users to perform tasks without unnecessary strain or difficulty.

Increased Productivity

- Faster Turnaround: The combination of maneuverability, stability, and ease of access allows for quicker setup and execution of tasks. This increased productivity is essential in busy environments where time is of the essence.

Adaptability to Various Applications

- Multi-functional Use: The compact design makes it suitable for a wide range of applications, from agricultural settings to industrial environments. This adaptability means that the HCYY11112017 can be utilized across different projects without sacrificing performance.

In summary, the compact design of the HCYY11112017 Towing and Lifting Cylinder not only enhances usability in tight spaces but also contributes to overall operational efficiency. By combining space efficiency, improved maneuverability, versatile integration, enhanced stability, and ease of access, this cylinder proves to be an invaluable asset for professionals working in confined environments.

Forklift Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Dodieties ekskursijā uz mūsu VR rūpnīcu:

Dodieties ekskursijā uz mūsu VR rūpnīcu ar šādiem elementiem.

Kā darbojas autoiekrāvēja hidrauliskais cilindrs?

Hidrauliskā cilindra pielietojums: