1.5KW Without Cooling Fan Standard Hydraulic Power Unit Pack

Kā viens no hidraulisko cilindru ražotājiem, piegādātājiem un eksportētājiem, mēs piedāvājam hidrauliskos cilindrus un daudzus citus produktus.

Lūdzu, sazinieties ar mums, lai saņemtu sīkāku informāciju.

Pasts:sales@hydraulic-cylinders.net

Hidraulisko cilindru ražotājs, piegādātājs, eksportētājs.

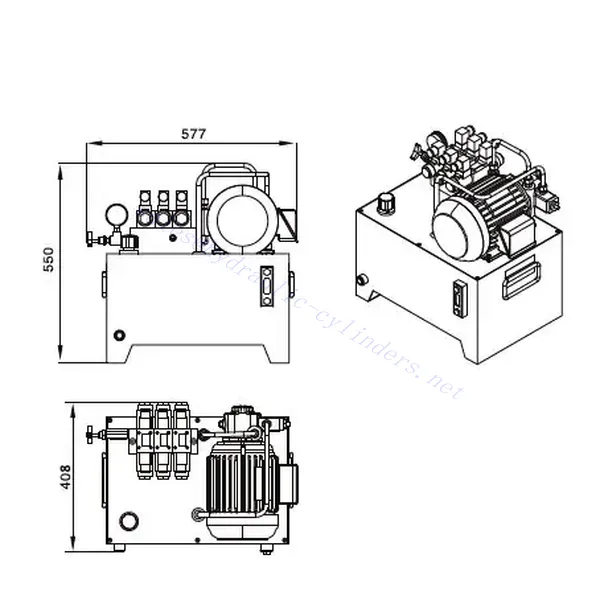

1.5KW Without Cooling Fan Standard Hydraulic Power Unit Pack

The 1.5KW without cooling fan standard hydraulic power unit package is a high-performance hydraulic power unit that provides reliable and efficient power for various industrial applications. With its strong power output, compact design, and no cooling fan, this power unit offers the best functionality and versatility for hydraulic systems requiring a compact and fanless solution. Whether used for machine tools, material handling equipment, or other hydraulic power machinery, the 1.5KW standard hydraulic power unit package without a cooling fan ensures consistent power delivery and efficient operation.

Standard Hydraulic Power Unit Packs Model Description:

1.5KW Without Cooling Fan Standard Hydraulic Power Unit Pack Parameter:

Standard Hydraulic Power Unit Packs Specification:

Standard Hydraulic Power Unit Packs Optional Parts:

Standard Hydraulic Power Unit Packs Schematic diagram:

Standard Hydraulic Power Unit Packs Key Characteristics and Benefits:

- Powerful Performance:

- The 1.5KW Fanless standard Hydraulic Power unit package features a robust 1.5KW rating that provides ample power for various hydraulic applications.

- Its high-performance motors ensure reliable and consistent power delivery, enabling the smooth operation of hydraulic machinery.

- Compact Design:

- This powerplant is designed with a compact form factor, making it ideal for installations with limited space or compact configurations.

- Its small footprint makes integrating into existing hydraulic systems easy without compromising performance or power output.

- Fanless Cooling System:

- 1.5KW No Cooling Fan The standard hydraulic power unit package is designed without cooling fans, eliminating the need for regular fan maintenance and reducing the risk of fan-related failures.

- The absence of cooling fans will also reduce noise levels and contribute to a quieter work environment.

- Standard Configuration:

- Equipped with standard hydraulic components such as motors, pumps, reservoirs, and control valves, this power unit offers compatibility with a wide range of hydraulic systems.

- The standard configuration simplifies installation and replacement, ensuring ease of use and compatibility with existing hydraulics.

How To Bleed A Hydraulic Cylinder On A Dump Truck?

To disassemble a hydraulic cylinder, follow these general steps:

- Safety Precautions:

- Before starting, ensure the hydraulic system is depressurized and the power source is disconnected.

- Use appropriate personal protective equipment, such as gloves and safety goggles, to protect yourself from any potential hazards.

- Positioning and Support:

- Place the hydraulic cylinder on a stable work surface, ensuring it is adequately supported to prevent accidental movement or damage.

- Remove External Components:

- Disconnect any external components attached to the cylinder, such as hoses, fittings, or mounting brackets.

- Use suitable tools, such as wrenches or pliers, to loosen and remove these components carefully.

- Drain Hydraulic Fluid:

- Locate the drain plug or valve on the cylinder and remove it to allow the hydraulic fluid to drain into a suitable container.

- Position the cylinder in a way that facilitates complete drainage.

- Disassemble End Caps:

- Identify the end caps of the hydraulic cylinder. They are usually located at each end of the cylinder barrel.

- Remove bolts, screws, or fasteners, securing the end caps using the appropriate tools.

- If necessary, gently tap the end caps with a rubber mallet to break any seal or adhesive bond.

- Separate Cylinder Components:

- With the end caps removed, carefully slide out the piston and piston rod from the cylinder barrel.

- Please pay attention to any seals, bearings, or bushings present and remove them as necessary.

- Take note of the order and orientation of the components for easier reassembly.

- Inspect and Clean Components:

- Inspect each disassembled component for signs of wear, damage, or contamination.

- Clean all components using an appropriate solvent or cleaner to remove dirt, debris, or old lubricant.

- Use a soft cloth or brush to gently clean the surfaces without causing any damage.

- Replace or Repair Components:

- If any components show significant wear or damage, consider replacing them with new ones.

- Repair or rebuild components, such as replacing seals or reconditioning the piston rod.

- Reassembly:

- Follow the reverse order of disassembly to reassemble the hydraulic cylinder, ensuring proper alignment and orientation of components.

- Lubricate the appropriate parts with recommended hydraulic fluid or lubricant during reassembly.

- Tighten all fasteners to the manufacturer’s specifications, using a torque wrench if necessary.

- Testing and Inspection:

- Once reassembled, conduct a thorough inspection to ensure all components are correctly aligned and secured.

- Test the hydraulic cylinder in a controlled manner to verify its functionality and check for any leaks or abnormal operation.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

Mums ir arī pusautomātiska krāsu ražošanas līnija lieliem baloniem, ko darbina ķēdes piedziņa, ar 60 kastu konstrukcijas jaudu vienā maiņā.

(5) Testēšana

Mums ir augstākās klases pārbaudes iekārtas un testēšanas stendi, lai nodrošinātu, ka balona veiktspēja atbilst prasībām.

We are one of the best hydraulic power unit pack manufacturers. We can offer comprehensive hydraulic power unit pack stock. We also provide corresponding lauksaimniecības pārnesumkārbas. Mēs esam eksportējuši savus produktus klientiem visā pasaulē un esam ieguvuši labu reputāciju, pateicoties mūsu izcilajai produktu kvalitātei un pēcpārdošanas servisam. Mēs aicinām klientus no valsts un ārvalstīm sazināties ar mums, lai risinātu biznesa sarunas, apmainītos ar informāciju un... sadarboties ar mums!

Dodieties ekskursijā uz mūsu VR rūpnīcu:

Dodieties ekskursijā uz mūsu VR rūpnīcu ar šādiem elementiem.

Kā darbojas autoiekrāvēja hidrauliskais cilindrs?

Hidrauliskā cilindra pielietojums: