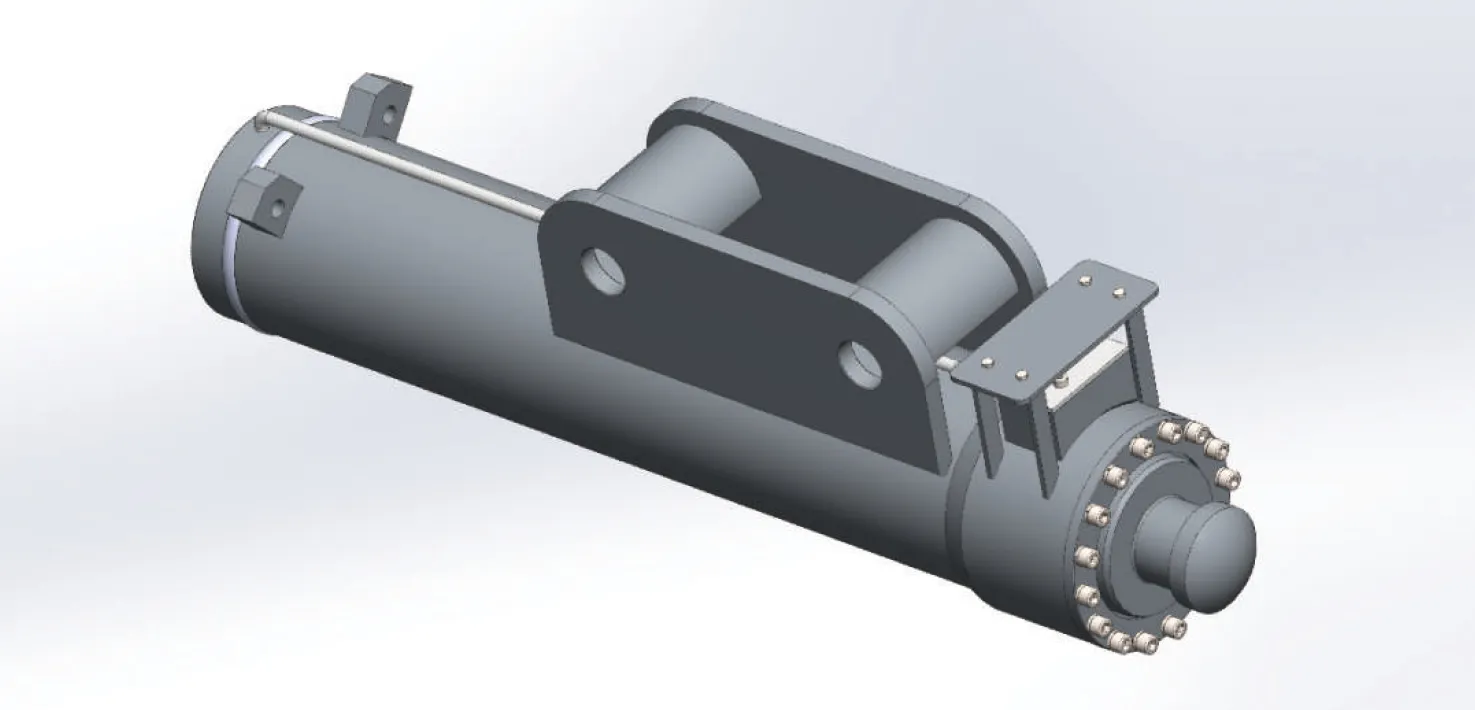

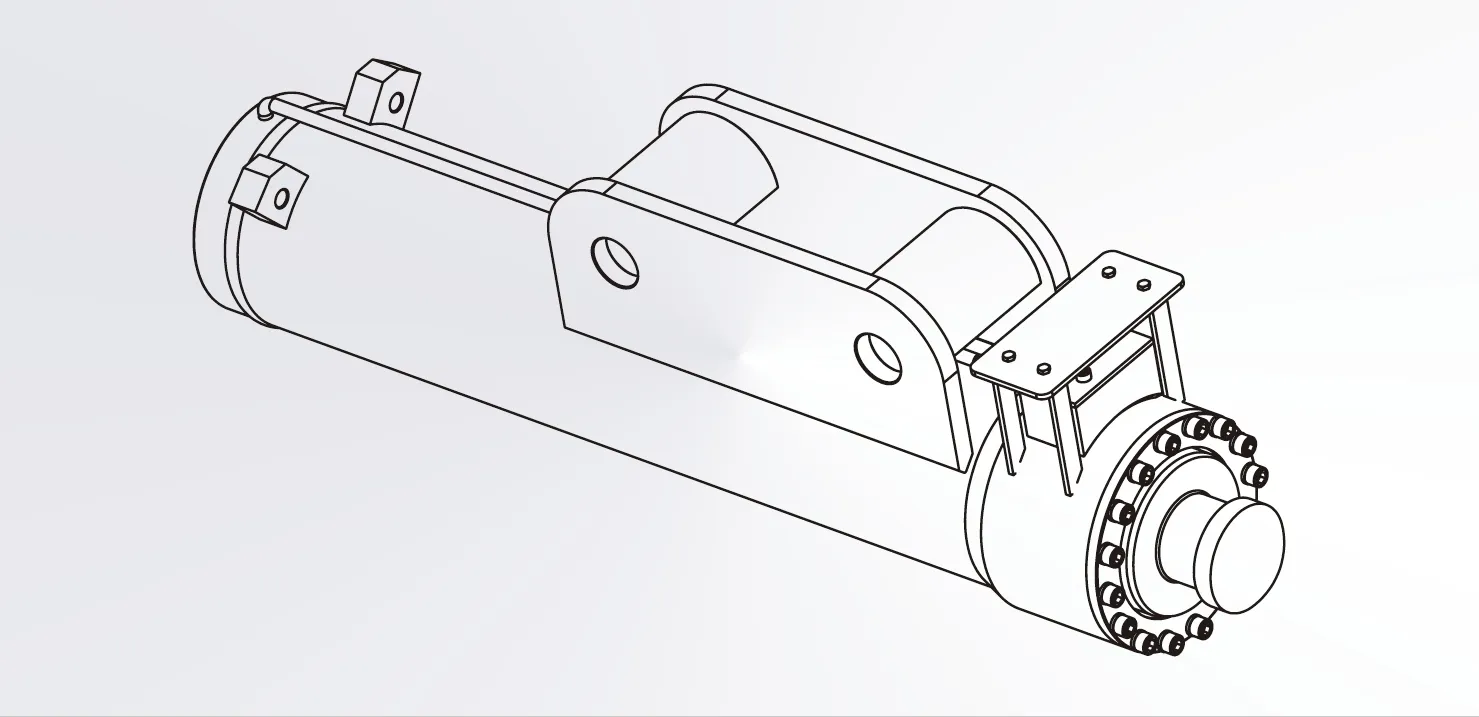

Support Hydraulic Cylinders For Crawler Crane

유압 실린더 제조업체, 공급 업체 및 기계 제품 수출 업체 중 하나로서 유압 실린더 및 기타 여러 제품을 제공합니다.

자세한 내용은 당사에 문의해 주세요.

메일:sales@hydraulic-cylinders.net

유압 실린더 제조업체 공급 업체 수출.

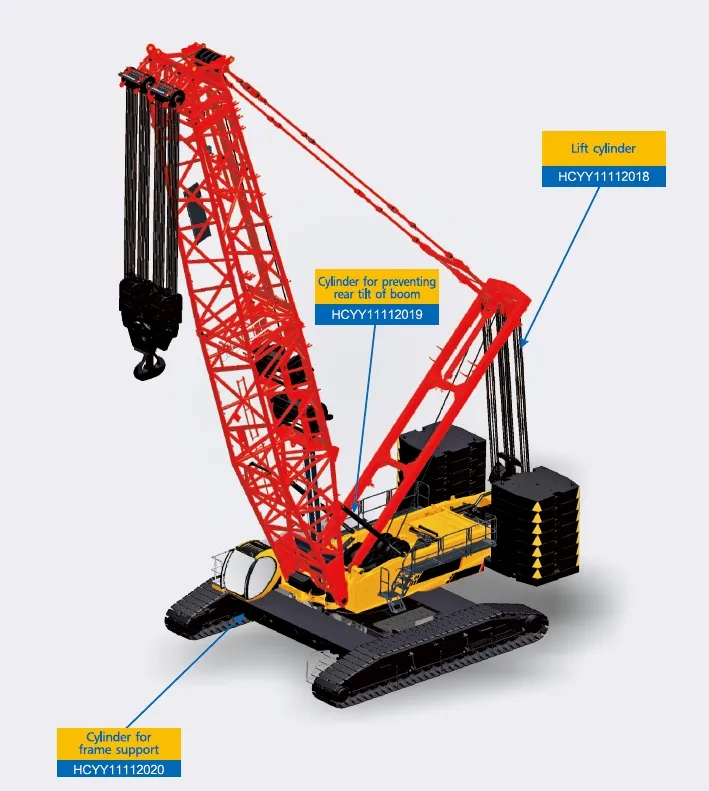

Support Hydraulic Cylinders For Crawler Crane

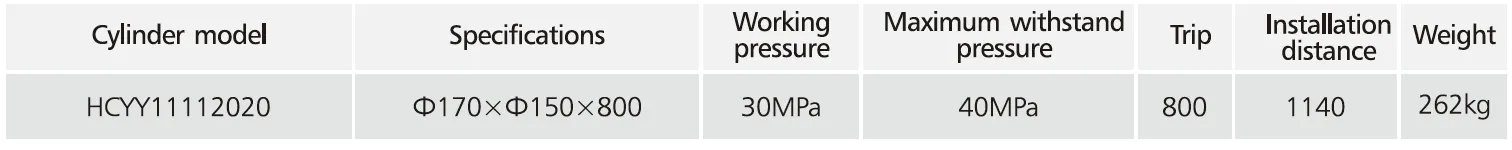

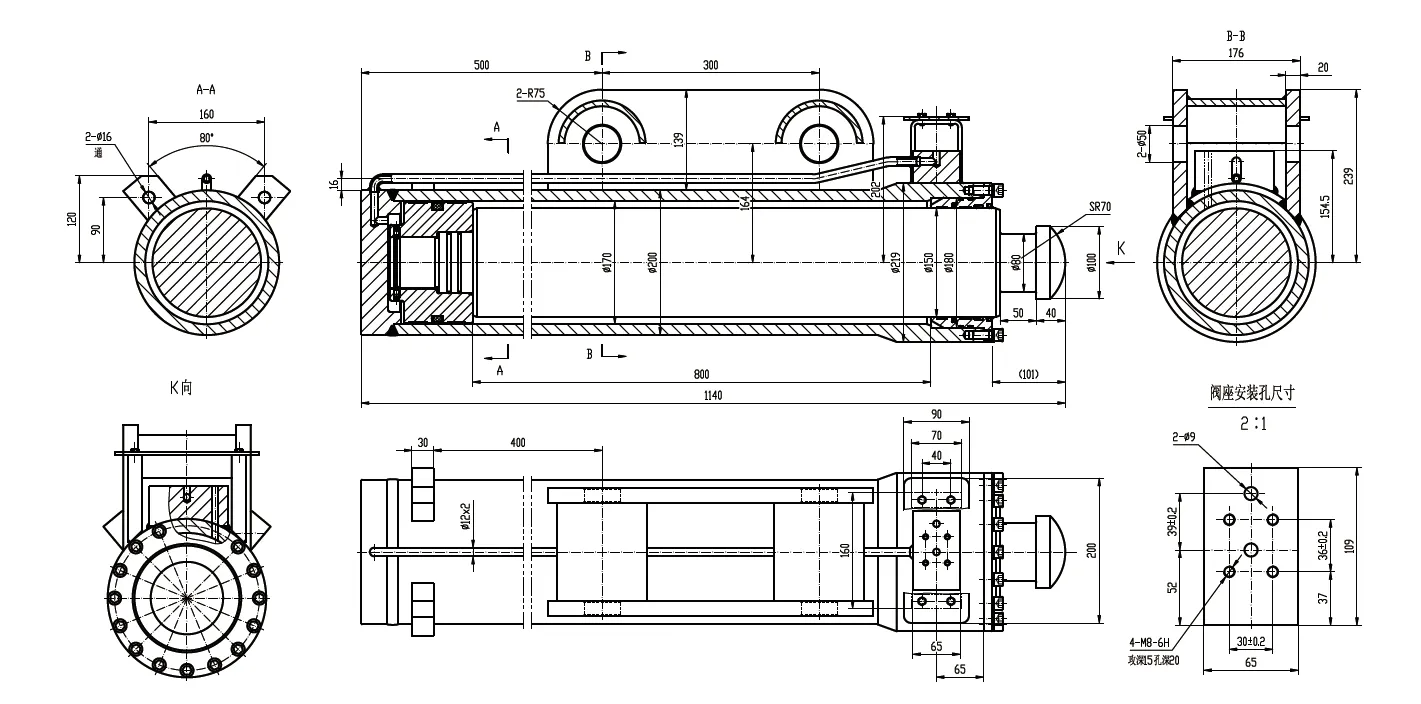

Support Hydraulic Cylinders For Crawler Crane Parameter:

Cylinder Series Of Crawler Crane:

Key Features of Support Hydraulic Cylinders For Truss Arm Crawler Crane:

High Load Capacity

The Support Cylinder excels with its impressive load capacity, enabling it to support substantial weights effortlessly. This feature makes it ideal for heavy-duty applications, such as large construction projects and infrastructure development. Operators can confidently lift and maneuver significant loads, knowing they have a reliable component that meets the demands of their most challenging tasks. This capability not only maximizes productivity but also enhances the overall efficiency of crane operations.

Durable Construction

Constructed from high-strength materials, the Support Cylinder is engineered to endure the rigors of demanding environments. Its durable construction resists wear and tear, ensuring that it performs reliably over time. This resilience means fewer replacements and repairs, allowing construction teams to focus on their work rather than maintenance issues. The longevity of this cylinder contributes to reduced downtime, making it a smart investment for any operation.

Corrosion Resistance

Corrosion can pose a significant threat to hydraulic components, but the Support Cylinder features advanced surface treatments that protect it from rust and corrosion. This added layer of defense ensures that the cylinder remains in excellent condition, even in harsh weather conditions or aggressive environments. By extending its lifespan, this corrosion resistance not only enhances reliability but also minimizes the need for costly repairs or replacements, ultimately boosting operational efficiency.

Compact Design

The compact design of the Support Cylinder enhances its versatility, allowing for easy integration into various crawler crane models. This space-efficient feature means that operators can maximize their crane’s capabilities without unnecessary bulk. The streamlined design facilitates quick installation and operation, enabling teams to adapt to different project requirements seamlessly. This adaptability fosters greater flexibility on the job site, making it easier to tackle a wide range of lifting tasks.

Precision Engineering

Precision is crucial in lifting operations, and the Support Cylinder is meticulously engineered to provide smooth operation and accurate load positioning. With tight manufacturing tolerances, this cylinder ensures that each lift is executed with utmost precision, significantly improving overall safety. Operators can trust that their loads will be positioned accurately, minimizing the risk of accidents and enhancing workflow efficiency. This level of precision not only protects valuable equipment but also contributes to a safer working environment for all.

In summary, the Support Cylinder stands out with its exceptional load capacity, durable construction, corrosion resistance, compact design, and precision engineering. Each of these features combines to deliver a reliable and efficient solution for construction projects, making it an indispensable asset for professionals in the industry.

How Does The Cylinder For Preventing Rear Tilt Enhance The Safety Of Crawler Crane Operations?

The design of the Support Cylinder is a masterpiece of engineering that significantly enhances stability during heavy lifting operations. Here’s how each feature contributes to its outstanding performance:

1. Impressive Load Capacity

The Support Cylinder is specifically engineered to support substantial weights, making it ideal for heavy-duty applications. This impressive load capacity ensures that even the heaviest loads can be lifted with confidence, greatly reducing the risk of tipping or swaying. By providing a solid foundation, this cylinder allows operators to focus on their tasks without the constant worry of stability, thus enhancing overall productivity.

2. Robust Construction

Crafted from high-strength materials, the cylinder is designed to withstand the rigors of demanding environments. This robust construction ensures that it maintains its structural integrity under intense pressure, providing a reliable support system that can handle dynamic forces during lifting operations. The durability of the materials used not only extends the lifespan of the cylinder but also enhances its ability to perform consistently, even in the most challenging situations.

3. Compact Design

One of the standout features of the Support Cylinder is its compact design, which allows for optimal placement within the crane’s frame. This strategic positioning lowers the center of gravity, significantly improving overall stability during operations. A lower center of gravity reduces the likelihood of tipping, especially when maneuvering heavy loads, making the cylinder an essential component for safe and efficient lifting.

4. Precision Engineering

Precision is paramount in lifting operations, and the Support Cylinder excels in this regard. With tight manufacturing tolerances, this cylinder guarantees smooth and controlled movements. This precision not only improves load positioning accuracy but also minimizes the chances of sudden shifts that could compromise stability. Operators can trust that their loads will be handled delicately and accurately, enhancing safety on the job site.

5. Corrosion Resistance

Corrosion can be a significant concern for hydraulic components, especially in harsh environments. The Support Cylinder features advanced surface treatments that protect it from rust and degradation. This corrosion resistance ensures that the cylinder maintains its performance over time, even in adverse conditions. By preventing wear and tear, this feature enhances reliability and prolongs the lifespan of the cylinder, contributing to sustained stability during heavy lifting tasks.

In summary, the Support Cylinder stands out as a cornerstone of stability and reliability in heavy lifting operations. Its impressive load capacity, robust construction, compact design, precision engineering, and corrosion resistance create a powerful support system. This cylinder not only enhances safety but also boosts efficiency, making it an invaluable asset for construction professionals. By investing in the Support Cylinder, operators can confidently elevate their performance and tackle even the most demanding projects.

Forklift Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: