Left and Right Forward Extension Cylinders for Forward Moving Forklift

유압 실린더 제조업체, 공급 업체 및 기계 제품 수출 업체 중 하나로서 유압 실린더 및 기타 여러 제품을 제공합니다.

자세한 내용은 당사에 문의해 주세요.

메일:sales@hydraulic-cylinders.net

유압 실린더 제조업체 공급 업체 수출.

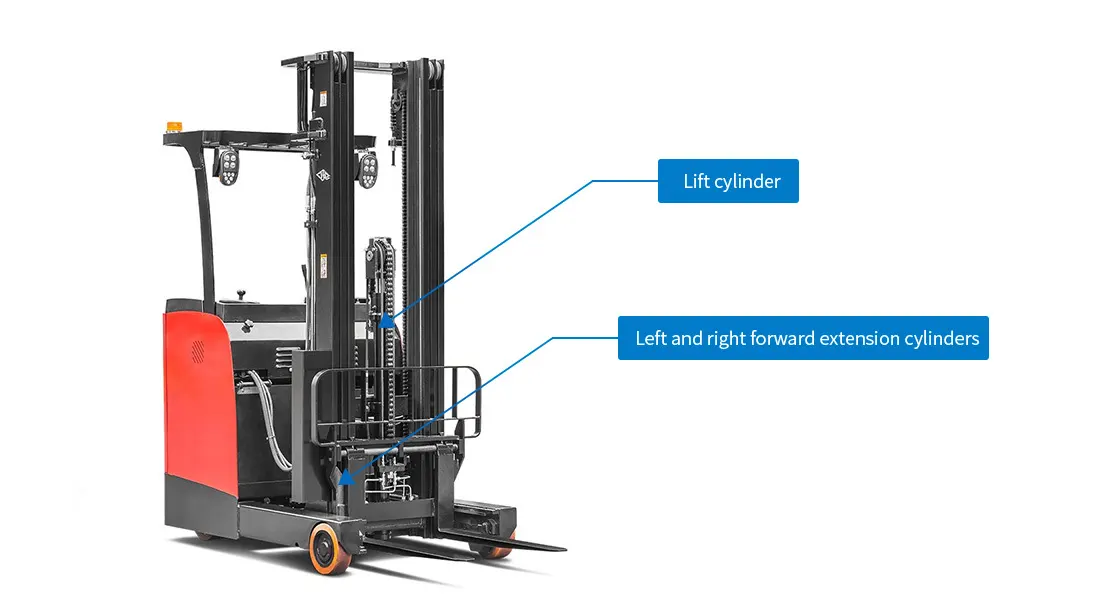

Left and Right Forward Extension Cylinders for Forward Moving Forklift

Left and right forward extension cylinders are vital components for forward moving forklifts, enhancing their operational efficiency and versatility. These hydraulic cylinders allow forklifts to extend their reach, making it easier to handle loads positioned at greater distances. By improving the forklift’s ability to maneuver and lift, these extension cylinders play a crucial role in various material handling applications, from warehouses to construction sites.

Left and right forward extension cylinders significantly enhance the functionality of forward moving forklifts. Their ability to provide increased reach, combined with durable construction and smooth operation, makes them essential for various material handling tasks. By understanding their features, proper usage methods, and maintenance requirements, operators can maximize efficiency and safety in their operations. Investing in high-quality extension cylinders ensures reliable performance and improved productivity, contributing to the overall success of any business reliant on effective material handling solutions.

Left and Right Forward Extension Cylinders for Forward Moving Forklift

Left and Right Forward Extension Cylinders for Forward Moving Forklift Technical Specifications:

Forward Moving Forklift Cylinder Series:

Key Features of Left and Right Forward Extension Cylinders for Forward Moving Forklift:

- Enhanced Reach: Left and right forward extension cylinders significantly increase a forklift’s reach, allowing operators to access loads positioned further away. This added reach is particularly beneficial during loading and unloading tasks, where precision and efficiency are paramount. By enabling operators to handle materials from a greater distance, these cylinders streamline workflows, reduce the time spent on each task, and ultimately lead to higher productivity levels.

- Durable Construction: Constructed from high-strength materials, these extension cylinders are designed to withstand the rigors of heavy-duty use. Their robust construction not only ensures exceptional durability but also significantly extends their lifespan. By minimizing wear and tear, these cylinders reduce the need for frequent replacements and repairs, translating into lower maintenance costs and improved operational efficiency for businesses.

- Smooth Operation: The hydraulic system integrated into the left and right forward extension cylinders guarantees that extension and retraction actions occur smoothly and efficiently. This feature minimizes jolting movements during operation, enhancing overall load stability. Operators benefit from improved control, which is crucial when handling delicate or heavy loads. The smooth operation also contributes to a safer working environment, reducing the risk of accidents and injuries.

- Compact Profile: These extension cylinders are designed with a compact profile that fits various forklift models seamlessly. This thoughtful design ensures that the cylinders do not impede the forklift’s maneuverability, allowing operators to navigate tight spaces with ease. Whether in crowded warehouses or busy construction sites, the compact nature of these cylinders enhances the forklift’s versatility, enabling it to perform effectively in diverse environments.

- 다양한 애플리케이션: Left and right-forward extension cylinders are suitable for a wide range of industries, including logistics, manufacturing, and construction. Their adaptability to various operational needs makes them a valuable addition to any forklift fleet. Whether lifting heavy materials in a manufacturing plant or reaching high stacks in a warehouse, these cylinders enhance the forklift’s capability, making it an indispensable tool for efficient material handling.

Use Cases for Left and Right Forward Extension Cylinders for Forward Moving Forklift:

Left and right forward extension cylinders significantly enhance the functionality of forward moving forklifts across various industries. Here are some key use cases that highlight their importance:

1. Warehouse Operations

In warehouse settings, forward extension cylinders enable forklifts to reach pallets stored at greater heights or distances. This capability allows for efficient stacking and retrieval of inventory, optimizing vertical space and facilitating quicker operations.

2. Loading and Unloading

During the loading and unloading of goods from trucks or shipping containers, these extension cylinders provide the necessary reach to handle items positioned further away. This feature minimizes the need for repositioning the forklift, saving time and improving workflow efficiency.

3. Order Picking

In environments where order picking is critical, left and right forward extension cylinders allow forklifts to access specific items located at various heights or distances. This precision improves accuracy in fulfilling orders and enhances overall productivity.

4. Cross-Docking

In cross-docking operations, where goods are transferred directly between inbound and outbound shipments, extension cylinders facilitate quick and efficient movement of pallets. This reduces handling time and ensures a smooth flow of materials through the supply chain.

5. Construction Sites

On construction sites, these extension cylinders enable forklifts to lift and place heavy materials, such as beams and concrete blocks, at various heights. Their ability to extend reach enhances safety and efficiency while handling large and cumbersome loads.

Looking for heavy-duty forklift cylinders? Check out our Heavy-Duty Hydraulic Cylinders.

Forklift Cylinder Production Area:

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line with a designed annual production capacity of million pieces. The special cylinder workshop has semi-automatic cleaning and assembly systems of various specifications with a designed annual production capacity of 200000 pieces. It is equipped with famous brand CNC machining equipment, machining centers, special equipment for high-precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of key equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

The machining shop is equipped with custom-made tilt guiderailturning centers, machining centers, high-speed honing machines, welding robots, and other relevant equipment, which can handle the machining work of cylinder tubes with 400mm Max ID and 6 meters of Max length.

We have a fully automatic water-based paint coating line for small and medium cylinders, which realizes automatic loading and unloading and automatic spraying robots with a designed production capacity of 4000 places per shift. We have another semi-automatic painting line for large-scale cylinders driven by a power chain, and the design capacity is 60 crates per shift.

To further improve product performance and establish the leadership position of our hydraulic cylinders in the industry, our company and zjimee jointly established a Comprehensive performance laboratory of hydraulic cylinders, hydraulic valves, and hydraulic pumps; the lab is computer-assisted testing using electro-hydraulic technology, the test conditions are preset by a computer which improves the test accuracy and system versatility, and the experimental data.

The automatic collection is realized through the application of sensors, and the output data, such as the internal leakage and load efficiency of the cylinder or the vale, are directly processed by the computer and converted to standard units (ml/min%). At the same time, to ensure the working safety of the hydraulic system, the state monitoring function is carried out for key performance parameters such as”oil temperature monitoring, liquid level monitoring, filter device monitoring,” etc. Among them, the hydraulic cylinder test stand can test the performance of the “load

efficiency “and” internal leakage” by readings. At the same time, it is equipped with a grating ruler measuring instrument that meets the requirements of all test items of hydraulic cylinder products according to the national standard.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: