HROD Round Hydraulic Cylinder Biaxial Type With Adjustable Cap

유압 실린더 제조업체, 공급 업체 및 기계 제품 수출 업체 중 하나로서 유압 실린더 및 기타 여러 제품을 제공합니다.

자세한 내용은 당사에 문의해 주세요.

메일:sales@hydraulic-cylinders.net

유압 실린더 제조업체 공급 업체 수출.

HROD Round Hydraulic Cylinder Biaxial Type With Adjustable Cap

The HROD biaxial adjustable cap round hydraulic cylinder is a state-of-the-art hydraulic component designed for exceptional performance and versatility across various industrial applications. Its innovative design, flexible cap functionality, and robust construction ensure precise control, durability, and reliability even in demanding environments. Whether for heavy lifting, propulsion, or positioning, the HROD biaxial model delivers optimal hydraulic power and efficiency, making it perfect for manufacturing, construction, and material handling.

The HRO series round cylinder is known for its safety, stability, and ease of maintenance. With an attractive design and high-quality construction, it is well-suited for a wide range of pressing applications.

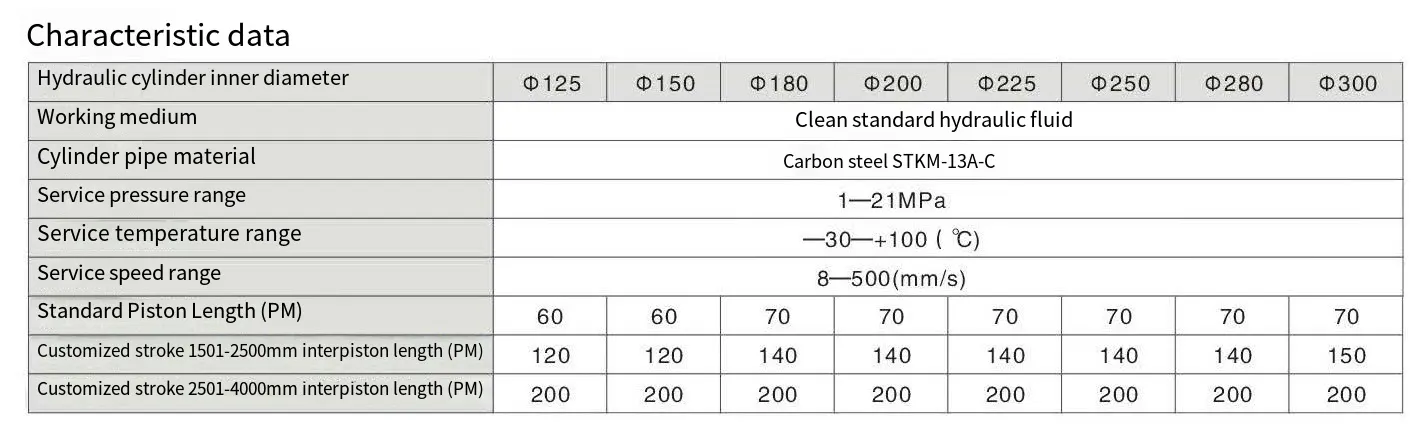

HROA Type Round Hydraulic Cylinder Characteristic Data:

HROA Type Round Hydraulic Cylinder Structure Diagram:

HROD Biaxial Type With Adjustable Cap Round Hydraulic Cylinder Characteristics:

- Adjustable Cap Design: The HROD two-shaft cylinder features an adjustable cap that allows precisely customized stroke lengths to meet specific application requirements.

- Robust Construction: This cylinder is built with high-quality materials, ensuring durability and longevity in demanding industrial environments.

- 정밀한 제어: HROD two-shaft cylinders provide superior control and positioning accuracy, enabling efficient and accurate operation.

- 다양한 애플리케이션: The hydraulic cylinder has a universal design and can be used in a variety of industries, including manufacturing, construction, and material handling.

- Reliable Performance: HROD two-shaft cylinders provide reliable performance even under heavy loads and challenging operating conditions.

HROD Biaxial Type With Adjustable Cap Round Hydraulic Cylinder Parameter:

HROD Biaxial Type With Adjustable Cap Round Hydraulic Cylinder 사용 방법:

- Mounting and Installation:

- Based on the specific requirements of your equipment or machine, determine the appropriate location to install the HROD two-shaft cylinder.

- Ensure the mounting surface is clean, level, and able to support the weight and load of the cylinder.

- Connection to Hydraulic System:

- Connect the HROD two-shaft cylinder using a compatible hydraulic hose or pipe to the hydraulic system.

- Ensure proper alignment and secure connections to prevent leaks and ensure optimal performance.

- Adjusting the Cap:

- The unique feature of the HROD two-shaft cylinder is its adjustable cover, which allows for fine-tuning of the cylinder stroke length.

- Use the provided adjustment mechanism to modify the cap position according to your application requirements.

- Carefully follow the manufacturer’s guidelines to ensure proper adjustments are made without exceeding cylinder limits.

- 실린더 작동하기:

- Activate the hydraulic system to apply pressure and initiate the movement of the HROD biaxial cylinder.

- The hydraulic control system is used to precisely control the cylinder’s extension, retraction, and positioning to achieve efficient and accurate operation.

What Applications Are Best Suited For Round Hydraulic Cylinders?

Industrial Machinery

Presses: Round hydraulic cylinders are crucial in metal forming processes, providing the necessary force to shape materials efficiently.

Lifts: They are used in scissors and platform lifts to safely raise and lower heavy equipment or personnel.

Construction Equipment

Excavators: Round cylinders power the boom and arm movements, allowing for effective digging and lifting.

Cranes: They are essential for controlling the movement of crane booms or jibs, facilitating heavy lifting and placement.

Automotive Industry

Hydraulic Lifts: Used in service stations for lifting vehicles for maintenance and repairs.

Assembly Line Equipment: They assist in moving components and parts during the manufacturing process.

Agricultural Equipment

Tractors: Round hydraulic cylinders are used in implements like loaders and tillers, providing the necessary force for different agricultural tasks.

Harvesters: They facilitate the operation of cutting and collecting mechanisms, improving efficiency during harvest.

Material Handling

Forklifts: Round hydraulic cylinders are integral for lifting and lowering loads, allowing for efficient warehouse operations.

Pallet Jacks: They enable the easy movement of heavy pallets, making them essential in logistics.

Mining

Drilling Rigs: These cylinders provide the force needed to operate drilling equipment, ensuring precision and power in tough environments.

Material Transport: Used in conveyors and other machinery to handle heavy materials safely.

Marine Applications

Deck Machinery: Round hydraulic cylinders control winches, cranes, and other ship equipment, facilitating loading and unloading operations.

Steering Systems: They are used in hydraulic steering systems to precisely control vessels.

Aerospace

Landing Gear: Round hydraulic cylinders are critical in retracting and extending landing gear, ensuring reliable aircraft operation.

Control Surfaces: They assist in the movement of flaps and ailerons, enhancing aircraft maneuverability.

How Does A One Way Hydraulic Cylinder Work?

A one-way, single-acting hydraulic cylinder operates using a hydraulic system to generate linear motion in one direction. It consists of a cylinder barrel, piston, piston rod, and hydraulic fluid. Here’s how it works:

- Hydraulic Fluid Supply:

- The hydraulic system supplies pressurized fluid, typically oil, to the cylinder through a hydraulic pump or power source.

- Cylinder Extension:

- When hydraulic fluid is supplied to the cylinder, it enters the cylinder barrel through an inlet port.

- The pressurized fluid pushes against the piston, causing it to move in the desired direction (typically extending the piston rod).

- As the fluid pressure increases, it overcomes the resistance or load on the piston, resulting in the extension of the piston rod.

- Sealing Mechanism:

- The cylinder barrel is sealed to prevent fluid leakage. It typically incorporates seals around the piston and piston rod, such as O-rings or lip seals.

- These seals ensure that the pressurized fluid acts only on one side of the piston, creating a pressure imbalance that drives the piston in the desired direction.

- Return Stroke:

- After the extension stroke, the hydraulic fluid is released or vented from the cylinder.

- The hydraulic system may use gravity, a spring, or an external force to retract the piston and piston rod to their initial positions.

- During the return stroke, the hydraulic fluid flows out of the cylinder through an outlet port.

- Load Support:

- The piston rod of the hydraulic cylinder is often connected to a load or mechanism that requires linear motion or force.

- As the piston extends or retracts, it provides the necessary force to move or support the load.

- Control and Valves:

- To control the extension and retraction of the one-way hydraulic cylinder, the hydraulic system incorporates valves, such as check valves or directional control valves.

- These valves regulate the flow of hydraulic fluid, allowing it to enter and exit the cylinder in the desired direction.

- Application Specifics:

- One-way hydraulic cylinders are commonly used in applications where force or motion is required in only one direction, such as lifting, pushing, or clamping.

- They are often found in hydraulic jacks, hydraulic presses, dump trucks, and various other industrial and mobile equipment.

Capability & Capacity Of Factory:

(1) Assembly

Our facility boasts a top-tier independent research and development assembly platform dedicated to hydraulic cylinder production. We operate four semi-automatic lifting cylinder assembly lines and one fully automatic tilt cylinder assembly line, with an impressive annual production capacity of 1 million cylinders.

In our specialized cylinder workshop, we utilize a semi-automatic cleaning assembly system designed for various specifications, capable of producing 200,000 cylinders annually. Our workshop is equipped with advanced CNC machining equipment, a machining center, high-precision cylinder processing tools, robot welding machines, automatic cleaning systems, and an automated cylinder assembly line. Additionally, we have a fully automated painting production line.

With over 300 pieces of critical equipment, our optimal resource allocation ensures that we meet the strict accuracy and quality standards required by our clients. This commitment to efficiency and precision positions us as a leader in the hydraulic cylinder industry.

(2) Machining

Our machining shop features state-of-the-art equipment, including a customized inclined rail turning center, a precision machining center, a high-speed honing machine, and advanced welding robots. This sophisticated setup enables us to efficiently process cylinder tubes with a maximum inner diameter of 400mm and a length of up to 6 meters.

With our cutting-edge technology, we ensure high-quality machining that meets the diverse needs of hydraulic cylinder production.

(3) Welding

(4) Painting & Coating

Our facility features advanced automatic water-based paint coating lines specifically designed for small and medium-sized cylinders. These lines utilize robotic technology for efficient loading, unloading, and spraying, achieving a remarkable production capacity of 4,000 pieces per shift.

In addition, we operate a semi-automatic paint production line for large cylinders, powered by a robust power chain, with a designed capacity of 60 cases per shift. This combination of automation and efficiency ensures high-quality finishes for all our hydraulic cylinders.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are a renowned manufacturer of 유압 실린더, recognized as one of the best in the industry. Our extensive product line includes a wide range of hydraulic cylinders tailored to meet various applications. In addition to hydraulic cylinders, we also provide high-quality agricultural gearboxes, ensuring our customers have access to comprehensive solutions for their machinery needs.

With a commitment to excellence, we have successfully exported our products to clients worldwide, earning a strong reputation for superior product quality and exceptional after-sales service. Our dedication to customer satisfaction has positioned us as a trusted partner in both domestic and international markets.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: