Foot Joint Two Stage Telescopic Hydraulic Cylinder

유압 실린더 제조업체, 공급 업체 및 기계 제품 수출 업체 중 하나로서 유압 실린더 및 기타 여러 제품을 제공합니다.

자세한 내용은 당사에 문의해 주세요.

메일:sales@hydraulic-cylinders.net

유압 실린더 제조업체 공급 업체 수출.

Foot Joint Two Stage Telescopic Hydraulic Cylinder

The foot joint two-stage telescopic hydraulic cylinder is an advanced hydraulic component that provides efficient and reliable power transmission in a wide range of industrial applications. With its innovative design, superior performance and versatility, this hydraulic cylinder offers precise control and increased productivity. Whether used in construction, material handling, or agricultural machinery, foot joint two-stage telescopic hydraulic cylinders are designed to optimize hydraulic operation and deliver superior results.

CX series compact cylinders are used for clamping cylinders. Its installation is small. Our factory has advanced hydraulic equipment, including a vertical and horizontal machining center and medium and large hydraulic cylinders. Thin cylinder production technology is excellent.

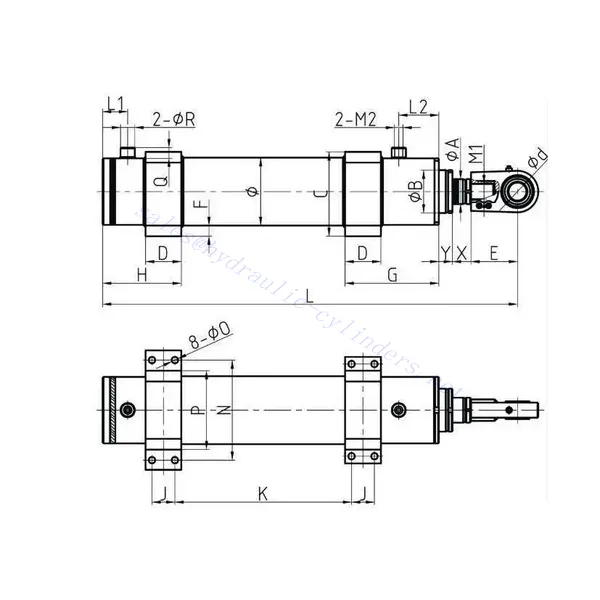

Foot Joint Two Stage Telescopic Hydraulic Cylinder Parameter:

Foot Joint Two Stage Telescopic Hydraulic Cylinder 주요 기능 및 이점:

- Two-Stage Telescopic Design:

- The foot joint two-stage telescopic hydraulic cylinder has a two-stage telescopic design that increases stroke length while maintaining a compact shrinkage size.

- This design allows for extended reach without compromising space constraints, making it ideal for applications where reach and compactness are both important.

- Foot Joint Construction:

- The cylinder is equipped with a foot joint structure to achieve smooth synchronous movement during the expansion phase.

- The foot joint mechanism ensures stability, accurate alignment, and good load-carrying capacity during operation.

- 정밀한 제어:

- The foot joint two-stage telescopic hydraulic cylinder provides superior control of expansion and contraction, allowing precise positioning and efficient operation.

- Precision control mechanism ensures smooth and controlled movement, improving overall productivity and accuracy.

- High Load-Bearing Capacity:

- Designed to handle heavy loads and demanding industrial applications, foot joint two-stage telescopic hydraulic cylinders provide outstanding load carrying capacity.

- It is capable of lifting, pushing or pulling heavy objects, making it a reliable choice for tasks that require a lot of strength.

Foot Joint Two Stage Telescopic Hydraulic Cylinder 사용 방법:

- 장착 및 설치:

- Determine the appropriate installation location for the foot joint two-stage telescopic hydraulic cylinder based on your equipment or mechanical requirements.

- 장착 표면이 튼튼하고 평평하며 실린더의 무게와 하중을 안전하게 지탱할 수 있는지 확인합니다.

- 유압 시스템 연결:

- 호환되는 유압 호스 또는 파이프를 사용하여 유압 실린더를 유압 시스템에 연결합니다.

- Align and secure the connections properly to prevent leaks and ensure optimal performance.

- 실린더 작동하기:

- Activate the hydraulic system to initiate the movement of the Foot Joint Two Stage Telescopic Hydraulic Cylinder.

- Use hydraulic control systems, such as valves or levers, to precisely control the extension and contraction of the cylinder for efficient operation.

How Do You Size A Hydraulic Cylinder?

의자에서 유압 실린더를 제거하려면 다음 단계를 따르세요:

- 작업 공간을 준비합니다:

- 의자 주변을 치워 안전하고 방해받지 않는 작업 공간을 만드세요.

- 의자나 주변 표면이 손상되지 않도록 바닥에 보호 커버나 천을 깔아주세요.

- 의자를 내립니다:

- 의자의 조절 레버 또는 제어 메커니즘을 사용하여 의자를 가장 낮은 위치로 내립니다.

- 이 단계를 거치면 실린더가 완전히 압축되어 쉽게 제거할 수 있습니다.

- 실린더를 찾습니다:

- 의자에 있는 유압 실린더를 확인합니다. 일반적으로 의자 바닥 근처에 위치하며 좌석 또는 의자의 메커니즘에 연결됩니다.

- 의자 시트를 제거합니다:

- 의자 시트를 분리할 수 있는 경우 실린더 또는 의자 베이스에 고정하는 장착 나사 또는 볼트를 찾습니다.

- 드라이버나 렌치 등 적절한 도구를 사용하여 나사나 볼트를 제거합니다.

- 의자에서 시트를 들어 올려 유압 실린더를 노출합니다.

- 의자를 지지합니다:

- 좌석이 없으면 의자가 불안정해지므로 의자가 넘어지지 않도록 받침대를 설치하세요.

- 상자나 나무 블록과 같은 튼튼한 물체를 사용하여 의자의 남은 구조물을 받쳐주세요.

- 실린더를 분리합니다:

- 유압 실린더와 의자 메커니즘 또는 베이스 사이의 연결 지점을 검사합니다.

- 의자 디자인에 따라 실린더를 고정하는 마운팅 브래킷, 클립 또는 나사가 있을 수 있습니다.

- 적절한 도구를 사용하여 실린더를 제자리에 고정하는 모든 패스너를 제거합니다.

- 패스너가 제거되면 실린더를 부드럽게 당기거나 흔들어 의자에서 분리합니다.

- Replace or Dispose of the Cylinder:

- If you are replacing the hydraulic cylinder, ensure you have a compatible replacement that matches the specifications of the old cylinder.

- Consult the chair manufacturer or a professional to obtain the correct replacement cylinder if necessary.

- If you are disposing of the cylinder, follow your local regulations and guidelines for proper disposal.

- Reassemble the Chair:

- Reattach the chair seat by aligning the screw holes and securing them with the appropriate screws or bolts if you removed the chair seat.

- Ensure the seat is firmly attached and stable before using the chair again.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best compact hydraulic cylinder manufacturers. We can offer comprehensive compact hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: