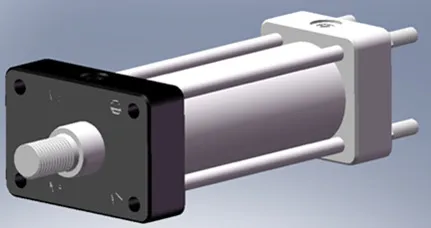

Low-Pressure Hydraulic Cylinder Front Flange

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

Low-Pressure Hydraulic Cylinder Front Flange

Looking for a reliable and durable solution for your low-pressure hydraulic systems? Our Low-Pressure Hydraulic Cylinder Front Flange is designed to deliver exceptional performance and longevity, making it the perfect choice for a wide range of applications. Engineered for low-pressure hydraulic systems, this front flange ensures reliable operation even in demanding environments. With its durable construction, it is built to withstand harsh conditions, providing long-lasting performance and reducing the need for frequent replacements. Whether you need an affordable front flange for hydraulic systems or a durable front flange for low-pressure applications, our product is easy to install and maintain, significantly reducing downtime and improving operational efficiency. Upgrade your hydraulic systems today with our Low-Pressure Hydraulic Cylinder Front Flange and experience unmatched reliability and performance!

Looking for a reliable and durable solution for your low-pressure hydraulic systems? Our Low-Pressure Hydraulic Cylinder Front Flange is designed to deliver exceptional performance and longevity, making it the perfect choice for a wide range of applications. Engineered for low-pressure hydraulic systems, this front flange ensures reliable operation even in demanding environments. With its durable construction, it is built to withstand harsh conditions, providing long-lasting performance and reducing the need for frequent replacements. Whether you need an affordable front flange for hydraulic systems or a durable front flange for low-pressure applications, our product is easy to install and maintain, significantly reducing downtime and improving operational efficiency. Upgrade your hydraulic systems today with our Low-Pressure Hydraulic Cylinder Front Flange and experience unmatched reliability and performance!

Low-pressure Hydraulic Cylinder Front Flange Technical Specifications:

Key Features of Our Hydraulic Cylinder Front Flange:

Our Low-Pressure Hydraulic Cylinder Front Flange is engineered to deliver exceptional performance and durability for your hydraulic systems. Here’s what makes it stand out:

- Reliable Performance: Designed specifically for low-pressure hydraulic systems, this front flange ensures smooth and efficient operation, even in demanding conditions.

- Durable Construction: Built with high-quality materials, our Hydraulic Cylinder Front Flange for Low-pressure Systems is resistant to wear and tear, making it ideal for use in harsh environments.

- Easy Installation & Maintenance: The user-friendly design of our Front Flange for Hydraulic Cylinders allows for quick installation and hassle-free maintenance, minimizing downtime and maximizing productivity.

- Cost-Effective Solution: As one of the best low-pressure hydraulic cylinder front flanges on the market, our product offers a perfect balance of quality and affordability.

- Versatile Applications: Whether you need an affordable front flange for hydraulic systems or a durable front flange for low-pressure applications, this component is suitable for a wide range of industrial and marine uses.

Upgrade your hydraulic systems with our Low-Pressure Hydraulic Cylinder Front Flange and experience unmatched reliability, durability, and ease of use!

Applications Of Low-Pressure Hydraulic Cylinder Front Flange:

- Low-pressure hydraulic cylinders with front flanges find applications in various industries and systems that operate under lower hydraulic pressures.

- They are commonly used in industrial machinery, mobile equipment, and other systems where space constraints or specific mounting requirements exist.

- These cylinders are suitable for material handling, lifting mechanisms, conveyor systems, and other equipment requiring linear force or motion.

How To Control Hydraulic Cylinder Speed?

Controlling the speed of a hydraulic cylinder can be achieved through various methods. Here are a few common approaches:

- Flow Control Valves: Flow control valves are specifically designed to regulate the flow rate of hydraulic fluid entering or exiting the cylinder. These valves can be adjustable or fixed and are typically installed in the hydraulic lines connected to the cylinder. By adjusting the valve’s opening or restriction, you can control the amount of fluid allowed to pass through, thus regulating the speed of the cylinder’s movement.

- Throttle Valves: Throttle valves, also known as speed control valves, are specifically designed to control the velocity of hydraulic actuators. They are typically placed in the hydraulic lines near the cylinder. Throttle valves restrict the flow of hydraulic fluid, creating a pressure drop and controlling the speed of the cylinder’s movement.

- Variable Displacement Pump or Motor: Using a variable displacement pump or motor in the hydraulic system allows for control over the flow rate and, consequently, the speed of the cylinder. By adjusting the displacement of the pump or motor, the amount of hydraulic fluid being supplied to the cylinder can be controlled, affecting the cylinder’s speed.

- Proportional Valves: Proportional valves offer precise control over the flow rate and speed of the hydraulic cylinder. These valves use electronic or electrical signals to modulate the valve opening, allowing for accurate and proportional control of the cylinder’s speed.

- Accumulators: Hydraulic accumulators store pressurized hydraulic fluid, which can be released to supplement the flow rate during periods of high demand. By incorporating accumulators into the system, you can enhance the speed control of the hydraulic cylinder, particularly during acceleration or deceleration phases.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces; Special cylinder workshop is equipped with various specifications semi-automatic cleaning assembly system, designed annual production capacity of 200,000. Equipped with famous CNC machining equipment, machining center, high-precision cylinder processing special equipment, robot welding machine, automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing key equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality requirements of products.

(2)Machining

The machining shop is equipped with customized inclined rail turning center, machining center, high-speed honing machine, welding robot and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating line, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift; We also have a semi-automatic paint production line for large cylinders, powered by a power chain, with a design capacity of 60 cases per shift.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.  We are one of the best low-pressure hydraulic cylinder manufacturers. We can offer wide low-pressure hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

We are one of the best low-pressure hydraulic cylinder manufacturers. We can offer wide low-pressure hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: