Y-HG1 Metallurgical Hydraulic Cylinder

In qualità di uno dei produttori, fornitori ed esportatori di prodotti meccanici, offriamo cilindri idraulici e molti altri prodotti.

Per maggiori dettagli, contattateci.

Posta:sales@hydraulic-cylinders.net

Produttore fornitore esportatore di cilindri idraulici.

Y-HG1 Metallurgical Hydraulic Cylinder

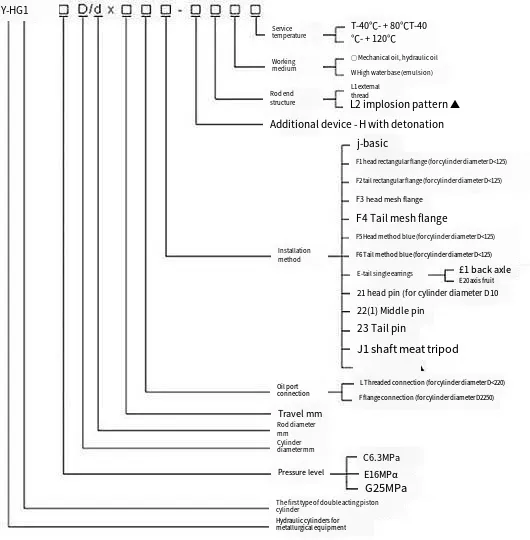

Y-HG1 series metallurgical equipment hydraulic cylinder is a double-acting piston cylinder, and the cylinder diameter is generally in the range of 40~320mm, the working pressure <=16MPA, the hydraulic oil mechanical system can be used for milk transport and other working medium, installation flange, earrings, pins, release device (base) and different types.

High precision CNC honing machine, automatic welding machine, vertical, horizontal machining center, gantry machining center, CNC lathe, and other processing equipment, product quality is stable and guaranteed.

Metallurgical Hydraulic Cylinder Parameter:

(1)Axial Tripod Type Metallurgical Hydraulic Cylinder Parameter

(2)Head Method Orchid Type Metallurgical Hydraulic Cylinder

(3)Head Pin Type Metallurgical Hydraulic Cylinder

(4)Head Rectangular Flange Type Metallurgical Hydraulic Cylinder

(5)Head Round Flange Type Metallurgical Hydraulic Cylinder

(6) Middle Pin Type Metallurgical Hydraulic Cylinder

(7)Rear Method Orchid Type Metallurgical Hydraulic Cylinder

(8)Rear Pin Type Metallurgical Hydraulic Cylinder

(9)Rear Rectangular Flange Type Metallurgical Hydraulic Cylinder

(10)Rear Round Flange Type Metallurgical Hydraulic Cylinder

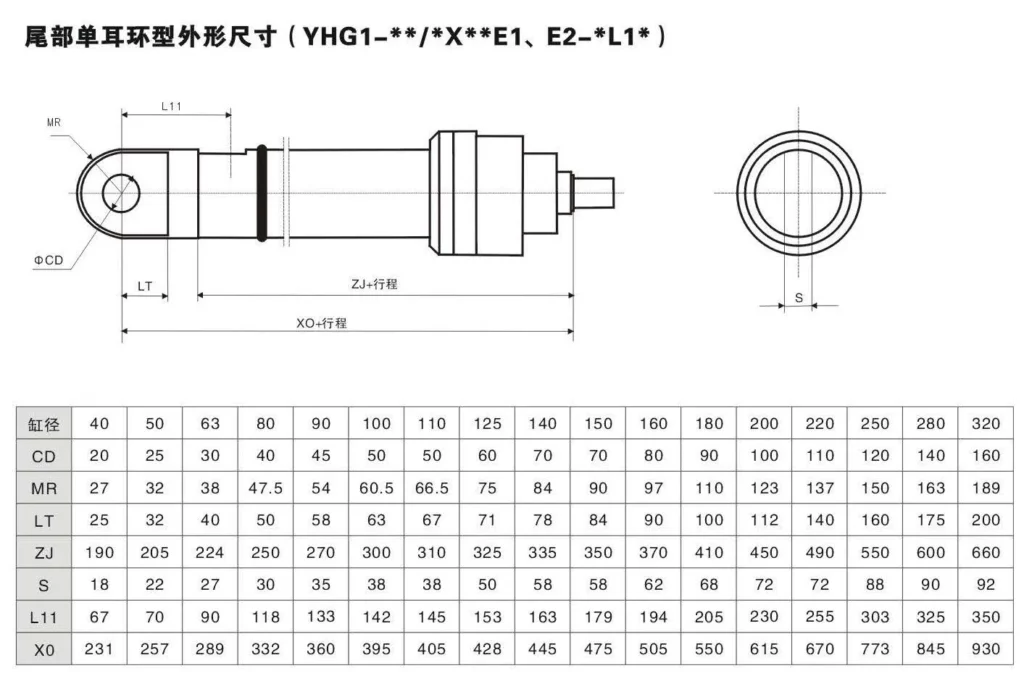

(11)Rear Single Earring Type Metallurgical Hydraulic Cylinder

(12) Y-HG1 Noraml Metallurgical Hydraulic Cylinder

Metallurgical Hydraulic Cylinder Technical Parameter:

Model example: Y-HG1-E40/22*50LJ1L10T1

Cilindro idraulico metallurgico Scope Of Application:

The hydraulic cylinder of Y-HG1 series metallurgical equipment is a double-acting piston cylinder. The cylinder diameter is generally in the range of 40~320mm, and the working pressure <=16MPA; its basic parameters include cylinder diameter, rod diameter, stroke, oil port size, and so on.

Come smontare un cilindro idraulico?

Taking apart a hydraulic cylinder requires careful disassembly to avoid damage and ensure safe handling. Here are the general steps to follow:

- Safety Precautions:

- Ensure the hydraulic system is depressurized and the cylinder is in a retracted position.

- Use appropriate personal protective equipment, such as gloves and safety glasses.

- Prepare a clean and organized workspace with adequate lighting and ventilation.

- Identify Cylinder Components:

- Familiarize yourself with the different parts of the hydraulic cylinder, including the cylinder body, piston, rod, seals, and end caps.

- Remove External Connections:

- Disconnect any hydraulic hoses, fittings, or other external connections attached to the cylinder.

- Use appropriate tools, such as wrenches or pliers, to loosen and remove the connections carefully.

- Secure the Cylinder:

- Place the cylinder securely in a vise or similar holding fixture, ensuring it is stable and won’t move during disassembly.

- Remove the Rod End Cap:

- Locate the rod end cap, which is typically situated at the end of the cylinder opposite the piston.

- Use the appropriate wrench or socket to loosen and remove the bolts securing the rod end cap.

- Tap the end cap gently with a rubber mallet if needed to break any seal or adhesive bond.

- Separate the Rod and Piston Assembly:

- Once the rod end cap is removed, carefully slide the rod and piston assembly out of the cylinder body.

- Support the weight of the assembly to prevent it from falling or causing damage.

- Disassemble the Rod and Piston Assembly:

- Examine the rod and piston assembly for retaining rings, snap rings, or other retaining devices.

- Use appropriate tools, such as pliers or snap ring pliers, to remove these retaining devices, allowing the disassembly of the assembly into its individual components.

- Take note of the order and orientation of each component for reassembly.

- Inspect and Clean:

- Inspect all the disassembled components for wear, damage, or signs of leakage.

- Clean each component thoroughly using an appropriate solvent or cleaning agent to remove dirt, debris, and hydraulic fluid residue.

- Dry the components completely before reassembly.

- Reassembly or Component Replacement:

- If necessary, replace any damaged or worn components with new ones following the manufacturer’s specifications.

- Reassemble the hydraulic cylinder in the reverse order of disassembly, ensuring proper alignment and orientation of components.

- Tighten bolts or fasteners to the manufacturer’s recommended torque specifications.

Capacità e capacità della fabbrica:

(1) Montaggio

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Lavorazione

L'officina di lavorazione è dotata di un centro di tornitura su rotaia inclinata personalizzato, di un centro di lavorazione, di una levigatrice ad alta velocità, di un robot di saldatura e di altre attrezzature correlate, in grado di gestire la lavorazione di tubi cilindrici con un diametro interno massimo di 400 mm e una lunghezza massima di 6 metri.

(3) Saldatura

(4) Verniciatura e rivestimento

Con linee automatiche di verniciatura a base d'acqua a cilindro di piccole e medie dimensioni, per realizzare il carico e lo scarico automatico con robot e la spruzzatura automatica, la capacità di progettazione è di 4000 pezzi per turno;

Disponiamo anche di una linea di produzione semiautomatica di vernici per cilindri di grandi dimensioni alimentata da una catena di potenza, con una capacità di progettazione di 60 casse per turno.

(5) Test

Disponiamo di strutture di ispezione e banchi di prova di prim'ordine per garantire che le prestazioni del cilindro siano conformi ai requisiti.

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding riduttori agricoli. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and collaborare con noi!

Visitate la nostra fabbrica VR:

Fate un tour della nostra fabbrica VR con quanto segue

Cilindro idraulico Applicazione: