Mobile Crane Luffing Cylinder

In qualità di uno dei produttori, fornitori ed esportatori di prodotti meccanici, offriamo cilindri idraulici e molti altri prodotti.

Per maggiori dettagli, contattateci.

Posta:sales@hydraulic-cylinders.net

Produttore fornitore esportatore di cilindri idraulici.

Mobile Crane Luffing Cylinder

The mobile crane luffing cylinder is essential in mobile crane systems and is designed to enhance these powerful machines’ vertical reach and lifting efficiency. This hydraulic cylinder plays a crucial role in adjusting the angle of the crane’s boom, allowing operators to extend or retract the boom smoothly and precisely.

The mobile crane luffing cylinder is vital for enhancing the vertical reach, lifting efficiency, and overall performance of mobile cranes. With its robust construction, precise angle adjustment, extended vertical space, and improved lifting capacity, this hydraulic cylinder empowers operators to navigate challenging construction sites and industrial environments with ease and safety. By following the recommended usage methods and maintenance practices, operators can maximize the longevity and performance of the mobile crane luffing cylinder, contributing to increased productivity, efficiency, and operator confidence in completing various lifting tasks. Invest in this essential hydraulic component to elevate the capabilities of your mobile crane, ensuring successful and efficient operations in diverse construction and industrial applications.

Mobile Crane Luffing Cylinder Key Characteristics:

- Robust Construction:

- The mobile crane luffing cylinder is built with high-quality materials, ensuring durability, strength, and resistance to heavy loads and harsh environmental conditions.

- It is designed to withstand the rigors of demanding construction sites and maintain optimal performance over extended periods.

- Precise Angle Adjustment:

- This hydraulic cylinder enables precise angle adjustment of the crane’s boom, providing operators with fine control over vertical reach and positioning.

- It offers smooth and responsive movement, allowing for accurate load placement and minimizing the risk of collisions or accidents.

- Extended Vertical Reach:

- The mobile crane luffing cylinder extends the crane’s vertical reach by adjusting the angle of the boom.

- It enhances the crane’s flexibility in accessing elevated work areas, such as high-rise construction sites or industrial installations.

- Lifting Efficiency:

- By optimizing the angle of the boom, the luffing cylinder enhances the lifting efficiency of the mobile crane.

- It allows for better load distribution, reducing stress on the crane’s components and improving overall lifting capacity.

Mobile Crane Luffing Cylinder Parameter:

| Product Name | Mobile Crane Luffing Cylinder |

| Features: | Realizing the up-and-down pitching rotation of the boom is the main driving force for lifting |

| Bore diameter: | 100mm~560mm |

| Rod diameter: | 50mm~480mm Stroke≤5000 mm |

| Pressure: | Maximum 36MPa |

| Luffing Cylinder Applications: | Mobile Crane |

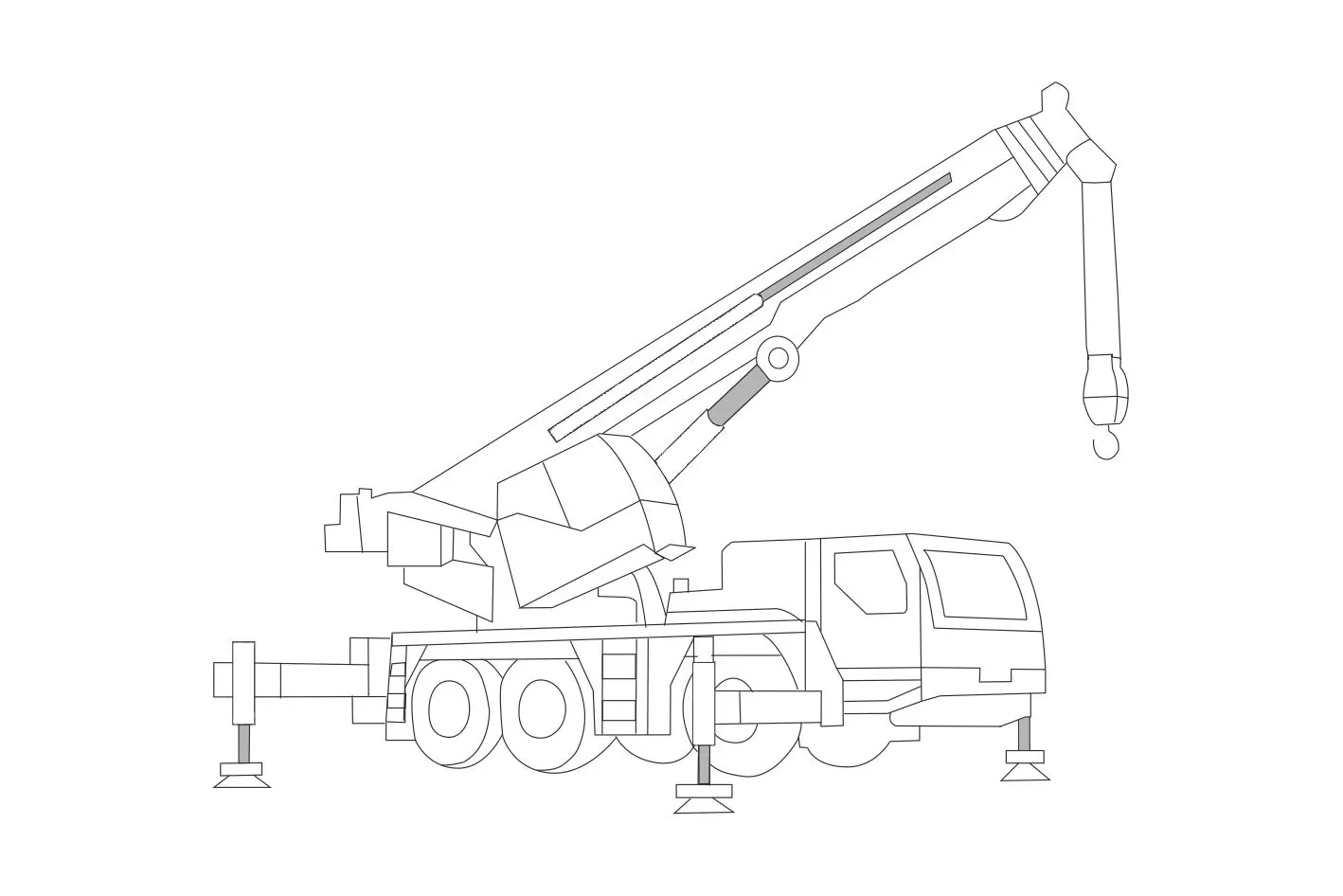

Mobile Crane Identification Diagram:

Usage Method Of Mobile Crane Luffing Cylinder:

- Safety Precautions:

- Before operating the mobile crane, ensure all safety guidelines and regulations are followed.

- Conduct a thorough inspection of the crane and its components, including the luffing cylinder, to ensure they are in proper working condition.

- Familiarize with Controls:

- Understand the control mechanisms and operating procedures specific to your mobile crane model.

- Identify the control for adjusting the luffing angle and ensure it functions properly.

- Luffing Angle Adjustment:

- Activate the control for the luffing cylinder, typically located in the operator’s cabin.

- Use the control to extend or retract the boom, adjusting the luffing angle as required for the lifting operation.

- Follow the load charts and manufacturer’s guidelines for the appropriate luffing angles based on the load weight and radius.

- Load Placement and Monitoring:

- Once the desired luffing angle is achieved, carefully position the load using the crane’s other controls, such as the hoist and swing mechanisms.

- Continuously monitor the load and adjust the luffing angle to maintain stability and safety during the lifting operation.

How To Release Pressure On Hydraulic System?

Releasing pressure from a hydraulic system is a necessary safety procedure that should be followed whenever maintenance or repair work is performed. Here are the general steps to release pressure from a hydraulic system:

- Identify the Power Source:

- Determine the power source supplying pressure to the hydraulic system, such as an electric motor, an engine-driven pump, or a manual pump.

- Locate the power switch or control valve associated with the power source.

- Shut Down the Power Source:

- Turn off the power switch or control valve to stop the power source from supplying pressure to the hydraulic system.

- If an engine powers the hydraulic system, shut off the engine completely.

- Engage the System Controls:

- Operate the control valves or switches on the hydraulic system to move actuators or components to neutral or resting positions.

- This step helps relieve residual pressure and allows the hydraulic fluid to flow back to the reservoir.

- Release Pressure at the Pump:

- If the hydraulic system has a pump with a pressure relief valve, locate the valve.

- Turn the pressure relief valve counterclockwise (or as specified by the manufacturer) to release pressure gradually.

- If available, check the system pressure gauge to ensure that pressure is relieved.

- Bleed Air from the System:

- Some hydraulic systems may have air trapped within the system, which can cause pressure buildup.

- To release air, open the air bleed valves or loosen fittings strategically to allow air to escape.

- Start from the lowest points in the system and work your way up to the highest points.

- Keep bleeding the system until a steady flow of hydraulic fluid is observed without air bubbles.

- Verify Pressure Release:

- Check the pressure gauge, if available, to ensure that the pressure has been fully released.

- Double-check the system controls to ensure that all actuators and components are neutral or resting.

Capacità e capacità della fabbrica:

(1) Montaggio

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Lavorazione

L'officina di lavorazione è dotata di un centro di tornitura su rotaia inclinata personalizzato, di un centro di lavorazione, di una levigatrice ad alta velocità, di un robot di saldatura e di altre attrezzature correlate, in grado di gestire la lavorazione di tubi cilindrici con un diametro interno massimo di 400 mm e una lunghezza massima di 6 metri.

(3) Saldatura

(4) Verniciatura e rivestimento

Con linee automatiche di verniciatura a base d'acqua a cilindro di piccole e medie dimensioni, per realizzare il carico e lo scarico automatico con robot e la spruzzatura automatica, la capacità di progettazione è di 4000 pezzi per turno;

Disponiamo anche di una linea di produzione semiautomatica di vernici per cilindri di grandi dimensioni alimentata da una catena di potenza, con una capacità di progettazione di 60 casse per turno.

(5) Test

Disponiamo di strutture di ispezione e banchi di prova di prim'ordine per garantire che le prestazioni del cilindro siano conformi ai requisiti.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding riduttori agricoli. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and collaborare con noi!

Visitate la nostra fabbrica VR:

Fate un tour della nostra fabbrica VR con quanto segue

Come funziona il cilindro idraulico del carrello elevatore?

Cilindro idraulico Applicazione: