Equipment Roller Press Cement Cylinder

In qualità di uno dei produttori, fornitori ed esportatori di prodotti meccanici, offriamo cilindri idraulici e molti altri prodotti.

Per maggiori dettagli, contattateci.

Posta:sales@hydraulic-cylinders.net

Produttore fornitore esportatore di cilindri idraulici.

Equipment Roller Press Cement Cylinder

The equipment roller press cement cylinder is a vital component in cement production, specifically designed to boost efficiency and productivity in manufacturing plants. Its exceptional characteristics and robust construction make it indispensable for effectively operating roller press machines.

With its high-pressure resistance, precision manufacturing, and advanced sealing technology, the equipment roller press cement cylinder ensures reliable and efficient performance. You can maximize the cylinder’s performance and longevity by adhering to recommended usage methods and maintenance practices. This not only enhances the efficiency of your cement operations but also contributes to overall productivity and profitability.

Cement Equipment Roller Press Cylinder Parameter:

| Product Name | Equipment Roller Press Cement Cylinder |

| Features: | Ensure the middle position of the clamp head |

| Bore diameter: | 200mm~700mm |

| Rod diameter: | 130mm~500mm Stroke: ≤500mm |

| Thrust force: | Max 5387KN (Cylinder diameter 700mm/pressure14MPa) |

| Cement Equipment Roller Press Cylinder Applications: | Cement Equipment |

Rod diameter: 130mm~500mm

Stroke: ≤500mm

(Cylinder diameter 700mm/pressure14MPa)

Costruzione robusta

The equipment roller press cement cylinder is crafted from high-quality materials, ensuring exceptional durability and longevity even in the demanding environments of cement plants. Its sturdy design allows it to handle heavy loads while maintaining optimal performance during continuous operation.

High Pressure Resistance

Engineered specifically for high-pressure applications, this cylinder excels in the intense conditions typical of cement roller press machines. It effectively manages the substantial forces generated while grinding and crushing raw materials, ensuring reliable and efficient operation.

Precision Manufacturing

Each cement equipment roller press cylinder is meticulously manufactured to achieve precise dimensions and tight tolerances. This level of precision facilitates smooth and accurate movement, significantly enhancing the performance and output of the roller press machine.

Advanced Sealing Technology

Featuring state-of-the-art sealing technology, this cylinder effectively prevents hydraulic fluid leakage. The reliable sealing mechanism not only minimizes downtime but also reduces maintenance costs, thus boosting the overall efficiency of the cement production process.

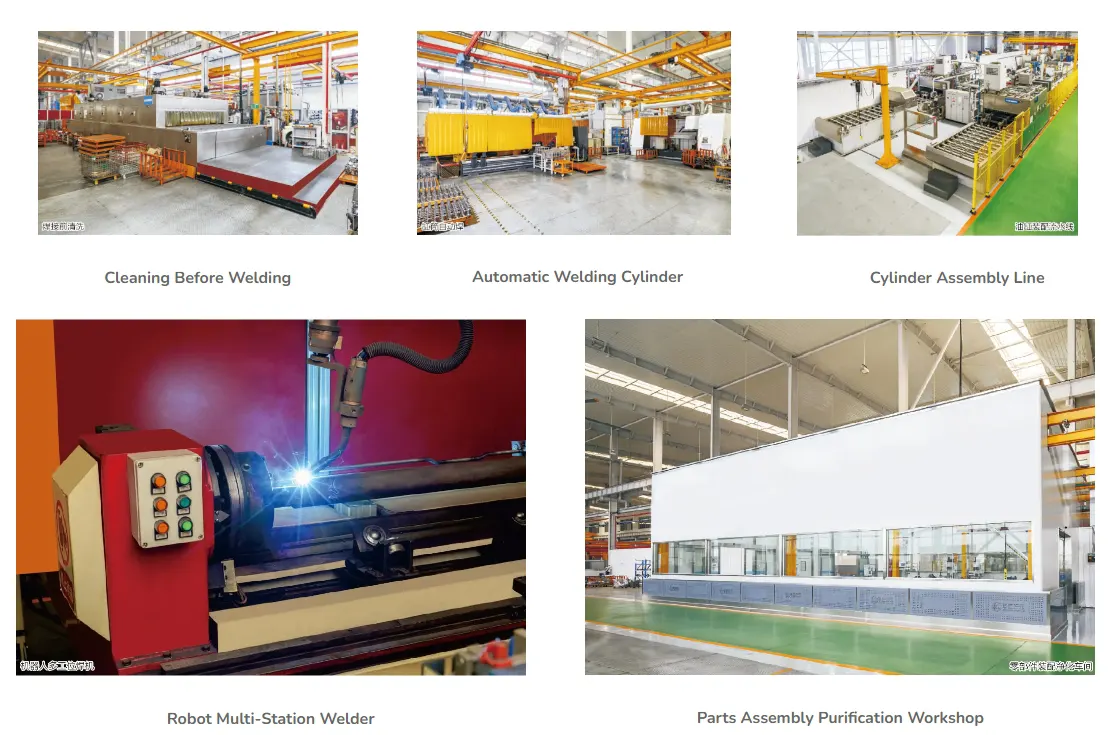

Electric Furnace Cylinder Factory:

Usage Method Of Cement Equipment Roller Press Cylinder:

Installation

Begin by following the manufacturer’s guidelines to securely install the equipment roller press cement cylinder onto the roller press machine. Ensure proper alignment and attachment to guarantee stable and safe operation.

Hydraulic Connection

Next, connect the cylinder to the hydraulic system of the roller press using the appropriate hydraulic fittings and hoses. It’s essential to verify that all connections are secure and free from leaks to maintain system integrity.

System Calibration

Calibrate the hydraulic system to ensure optimal performance from the equipment roller press cement cylinder. Adjust the pressure settings and flow rates according to the manufacturer’s recommendations to achieve the desired operational parameters.

Operation and Control

Activate the hydraulic system to initiate the operation of the roller press machine. The equipment roller press cement cylinder will engage with the pressing rollers, exerting the necessary force to efficiently grind and crush raw materials. Utilize the control panel or interface to monitor and adjust the cylinder’s position, pressure, and speed, ensuring precise and effective operation.

How Do Equipment Roller Press Cement Cylinders Improve Efficiency In Cement Production?

Enhanced Material Grinding

High-Pressure Application: The cylinders apply significant pressure on the raw materials, which helps break down the particles more effectively than conventional grinding methods. This process results in a finer product that enhances the quality of the final cement.

Improved Particle Distribution: The grinding action creates a more uniform particle size distribution, crucial for achieving consistent cement properties.

Reduced Energy Consumption

Lower Energy Costs: Due to their efficient grinding capability, these cylinders consume less energy, reducing operational costs. The energy savings can be substantial over long production runs.

Less Wear on Equipment: Efficient grinding reduces the strain on other components of the production line, leading to lower energy requirements for overall operations.

Continuous Operation

Robust Design: Built to withstand harsh conditions, equipment roller press cement cylinders can operate continuously without frequent breakdowns. This longevity is essential for maintaining high production rates.

Minimized Downtime: With less frequent maintenance needs and the ability to run continuously, production downtime is significantly reduced, allowing for a more consistent output.

Controllo di precisione

Tailored Processing: Operators can adjust parameters such as pressure and flow rates to suit specific materials and production requirements. This flexibility helps optimize the grinding process for different types of cement.

Quality Consistency: Precise control over the grinding process ensures that the quality of the cement remains consistent, which is critical for meeting industry standards and customer expectations.

Space Efficiency

Compact Design: The smaller footprint of roller press cylinders compared to traditional mills allows for more efficient use of space within the production facility. This can lead to better workflow and process integration.

Flexible Layouts: Their design allows for flexibility in plant layouts, enabling manufacturers to adapt to changing production needs or expand without significant structural changes.

Environmental Benefits

Lower CO2 Emissions: By consuming less energy and improving the efficiency of the grinding process, equipment roller press cement cylinders contribute to lower carbon emissions associated with cement production.

Resource Conservation: Efficient processing means less raw material waste, supporting more sustainable production practices.

Integration with Modern Technology

Automation and Monitoring: Many modern roller press systems have advanced monitoring and control systems that allow for real-time data analysis and adjustments. This integration enhances operational efficiency and responsiveness to production needs.

Compatibility with Other Technologies: These cylinders can be easily integrated into existing production lines, allowing for upgrades without complete system overhauls.

Capacità e capacità della fabbrica:

(1) Montaggio

Our facility boasts a top-tier independent research and development assembly platform dedicated to hydraulic cylinder production. We operate four semi-automatic lifting cylinder assembly lines and one fully automatic tilt cylinder assembly line, with an impressive annual production capacity of 1 million cylinders.

In our specialized cylinder workshop, we utilize a semi-automatic cleaning assembly system designed for various specifications, capable of producing 200,000 cylinders annually. Our workshop is equipped with advanced CNC machining equipment, a machining center, high-precision cylinder processing tools, robot welding machines, automatic cleaning systems, and an automated cylinder assembly line. Additionally, we have a fully automated painting production line.

With over 300 pieces of critical equipment, our optimal resource allocation ensures that we meet the strict accuracy and quality standards required by our clients. This commitment to efficiency and precision positions us as a leader in the hydraulic cylinder industry.

(2) Lavorazione

Our machining shop features state-of-the-art equipment, including a customized inclined rail turning center, a precision machining center, a high-speed honing machine, and advanced welding robots. This sophisticated setup enables us to efficiently process cylinder tubes with a maximum inner diameter of 400mm and a length of up to 6 meters.

With our cutting-edge technology, we ensure high-quality machining that meets the diverse needs of hydraulic cylinder production.

(3) Saldatura

(4) Painting & Coating

Our facility features advanced automatic water-based paint coating lines specifically designed for small and medium-sized cylinders. These lines utilize robotic technology for efficient loading, unloading, and spraying, achieving a remarkable production capacity of 4,000 pieces per shift.

In addition, we operate a semi-automatic paint production line for large cylinders, powered by a robust power chain, with a designed capacity of 60 cases per shift. This combination of automation and efficiency ensures high-quality finishes for all our hydraulic cylinders.

(5) Test

Disponiamo di strutture di ispezione e banchi di prova di prim'ordine per garantire che le prestazioni del cilindro siano conformi ai requisiti.

We are a renowned manufacturer of cilindri idraulici, recognized as one of the best in the industry. Our extensive product line includes a wide range of hydraulic cylinders tailored to meet various applications. In addition to hydraulic cylinders, we also provide high-quality agricultural gearboxes, ensuring our customers have access to comprehensive solutions for their machinery needs.

With a commitment to excellence, we have successfully exported our products to clients worldwide, earning a strong reputation for superior product quality and exceptional after-sales service. Our dedication to customer satisfaction has positioned us as a trusted partner in both domestic and international markets.

Why Choose Us?

Professional Expertise: Our team comprises industry professionals with extensive knowledge and experience in hydraulic systems, ensuring that we deliver top-notch products and services.

International Certifications: We adhere to strict quality standards and hold various international certifications, demonstrating our commitment to delivering reliable and safe hydraulic solutions.

Custom Solutions: We understand that each customer’s needs are unique. That’s why we offer customized hydraulic cylinders and gearboxes tailored to meet specific requirements.

Advanced Production Equipment: Our state-of-the-art manufacturing facilities utilize the latest technology and equipment, enabling us to produce high-quality products efficiently.

Comprehensive After-Sales Support: Our commitment to our customers extends beyond the sale. We provide ongoing support and maintenance services to ensure optimal performance of our products.

We invite customers from around the globe to reach out to us for business negotiations, information exchange, and collaboration opportunities. Together, we can achieve greater success in the hydraulic industry!

Visitate la nostra fabbrica VR:

Fate un tour della nostra fabbrica VR con quanto segue

Come funziona il cilindro idraulico del carrello elevatore?

Cilindro idraulico Applicazione: