Small Excavator Rotary Actuator

Sebagai salah satu produsen, pemasok, dan eksportir silinder hidrolik, Kami menawarkan silinder hidrolik dan banyak produk lainnya.

Silakan hubungi kami untuk informasi lebih lanjut.

Surat:sales@hydraulic-cylinders.net

Produsen pemasok eksportir silinder hidrolik.

Small Excavator Rotary Actuator

The small excavator rotary actuator is a powerful hydraulic component designed to enhance the versatility and performance of small excavators. This actuator is precisely engineered to provide precise rotation and control, enabling efficient operation in various construction and excavation tasks.

The small excavator rotary actuator is a crucial hydraulic component that enhances the versatility and performance of small excavators. With its compact design, precise rotation and control, versatile attachment compatibility, and smooth operation, this actuator empowers operators to tackle various construction and excavation tasks efficiently. By following the recommended usage methods and maintenance practices, operators can ensure optimal performance and longevity of the small excavator rotary actuator, resulting in increased productivity and successful completion of projects. Invest in this exceptional hydraulic actuator to elevate the capabilities of your small excavator and achieve superior results in your construction and excavation operations.

Small Excavator Rotary Actuator Key Characteristics:

- Compact Design and Robust Construction

- The Small Excavator Rotary Actuator features a compact design, making it ideal for small excavators without compromising power and performance.

- Built with high-quality materials and robust construction, this actuator ensures durability and longevity, even in demanding working conditions.

- Precise Rotation and Control

- This actuator delivers precise rotation and control, allowing operators to easily position and maneuver attachments such as buckets, augers, and grapples.

- It enables accurate and efficient operation, enhancing productivity and reducing the time required to complete excavation tasks.

- Versatile Attachment Compatibility

- The Small Excavator Rotary Actuator is compatible with various attachments, making it suitable for multiple applications.

- It can be used with buckets for digging, grapples for material handling, and augers for drilling, providing versatility and flexibility on the job site.

- Smooth and Efficient Operation

- Equipped with advanced hydraulic technologies, this actuator ensures smooth and efficient operation.

- It delivers excellent responsiveness, allowing operators to perform precise movements with ease and control.

Small Excavator Rotary Actuator Parameter:

| Product Name | Small Excavator Stick Cylinder |

| Features: | Control the movement of the forearm |

| Bore diameter: | 50mm~115mm |

| Rod diameter: | 25mm~70mm Stroke≤1000mm |

| Thrust force: | Maximum 305KN |

| Bore diameter: | 115mm/pressure29.4MPa) |

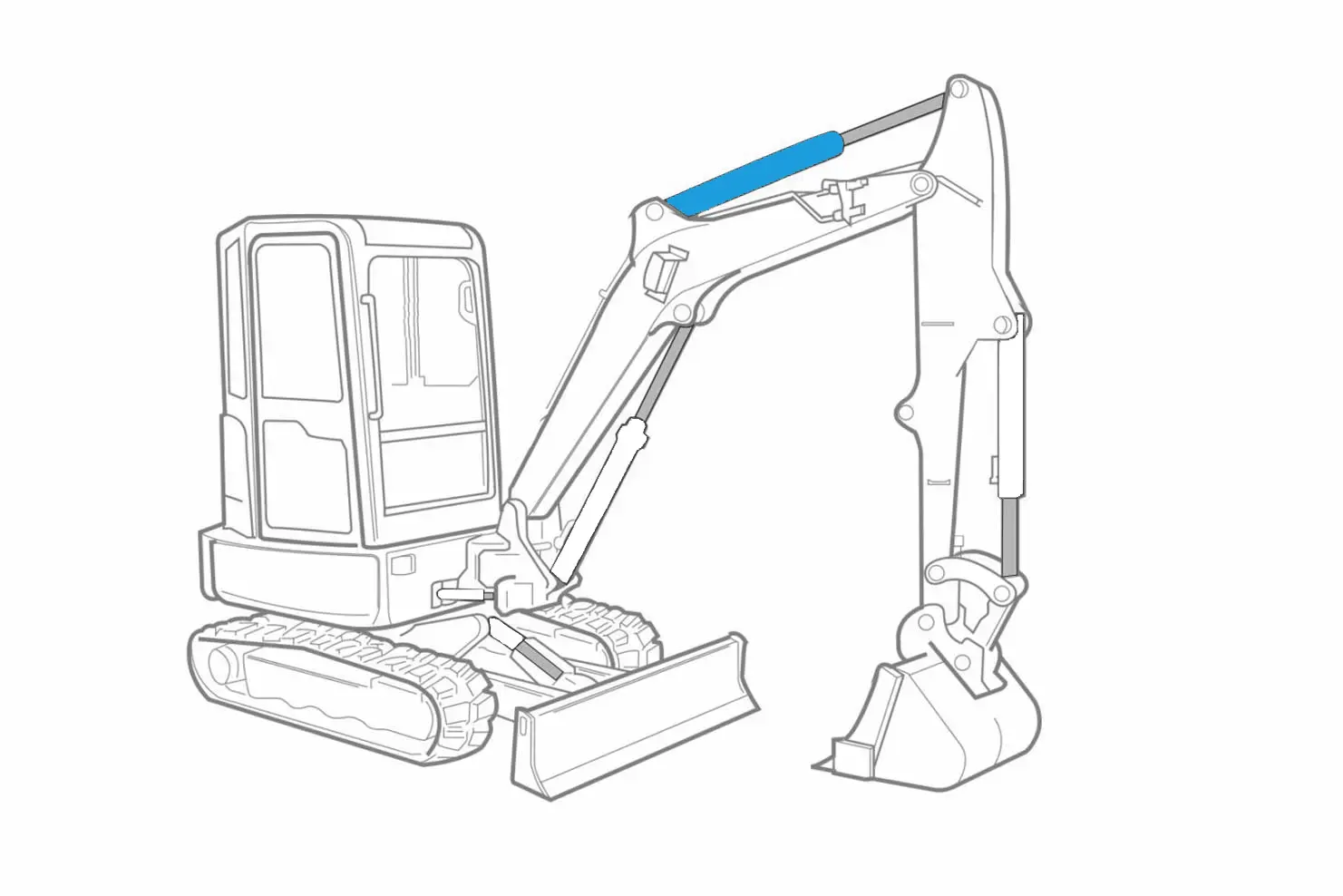

Small Excavator Rotary Actuator Identification Diagram:

Usage Method Of Small Excavator Rotary Actuator:

- Installation and Integration

- Begin by referring to the manufacturer’s instructions for proper installation of the Small Excavator Rotary Actuator.

- Ensure compatibility and securely attach the actuator to the excavator’s attachment mounting point.

- Follow the recommended torque specifications and use appropriate mounting hardware for a secure and reliable connection.

- Operational Considerations

- Familiarize yourself with the controls and operation of the small excavator, including the rotary actuator.

- Practice operating the excavator and actuator in a controlled environment before undertaking actual tasks.

- Adhere to safety guidelines and operate within the excavator’s load limits to prevent accidents and equipment damage.

- Attachment Usage and Control

- Attach the desired tool or accessory to the Small Excavator Rotary Actuator, such as a bucket, grapple, or auger.

- Utilize the actuator’s precise control to position and manipulate the attachment as required for the task at hand.

- Adjust the rotation speed and direction according to the specific requirements of the excavation or construction project.

What Size Cylinder For Excavator Thumb?

The size of the cylinder for an excavator’s thumb can vary depending on the specific requirements of the excavator and the intended use of the thumb attachment. The appropriate size of the cylinder is typically determined by considering factors such as the excavator’s operating weight, the desired lifting capacity of the thumb, and compatibility with the excavator’s hydraulic system.

To determine the suitable cylinder size for an excavator thumb, it is recommended to consult the manufacturer or supplier of the thumb attachment. They can provide guidance based on the excavator’s specifications and the thumb’s intended application.

It’s worth noting that excavator thumbs are available in various sizes and configurations to accommodate different excavator models and sizes. The thumb attachment typically consists of a central structure or frame that mounts to the excavator’s boom and a hydraulic cylinder that provides the gripping or clamping action. The cylinder size should be selected to ensure compatibility with the thumb attachment and to provide the required gripping force for the intended tasks.

When considering the cylinder size for an excavator’s thumb, it’s essential to strike a balance between having sufficient lifting capacity and ensuring that the excavator’s hydraulic system can adequately support the operation of the thumb. Oversizing the cylinder may strain the excavator’s hydraulic system excessively, while under sizing, may result in limited lifting capacity and reduced performance.

In summary, the size of the cylinder for an excavator thumb should be determined based on factors such as the excavator’s operating weight, desired lifting capacity, and compatibility with the thumb attachment and hydraulic system. Consulting the manufacturer or supplier of the thumb attachment is recommended to ensure proper sizing and optimal performance.

Kemampuan & Kapasitas Pabrik:

(1) Perakitan

Kami memiliki platform perakitan penelitian dan pengembangan independen kelas satu. Bengkel produksi silinder hidrolik memiliki empat jalur perakitan silinder pengangkat semi-otomatis dan satu jalur perakitan silinder kemiringan otomatis, dengan kapasitas produksi tahunan yang dirancang sebesar 1 juta keping. Bengkel silinder khusus dilengkapi dengan berbagai spesifikasi sistem perakitan pembersihan semi-otomatis dengan kapasitas produksi tahunan yang dirancang sebesar 200.000 dan dilengkapi dengan peralatan permesinan CNC yang terkenal, pusat permesinan, peralatan khusus pemrosesan silinder presisi tinggi, mesin las robot, mesin pembersih otomatis, mesin perakitan silinder otomatis, dan jalur produksi pengecatan otomatis. Peralatan penting yang ada lebih dari 300 set (set). Alokasi optimal dan penggunaan sumber daya peralatan yang efisien memastikan persyaratan akurasi produk dan memenuhi kebutuhan produk berkualitas tinggi.

(2) Pemesinan

Bengkel permesinan dilengkapi dengan pusat pembubutan rel miring yang disesuaikan, pusat permesinan, mesin pengasah berkecepatan tinggi, robot pengelasan, dan peralatan terkait lainnya, yang dapat menangani pemrosesan tabung silinder dengan diameter bagian dalam maksimum 400mm dan panjang maksimum 6 meter.

(3) Pengelasan

(4) Pengecatan & pelapisan

Dengan jalur pelapisan cat berbasis air otomatis silinder kecil dan menengah, untuk mencapai bongkar muat robot otomatis dan penyemprotan otomatis, kapasitas desain 4000 buah per shift;

Kami juga memiliki lini produksi cat semi-otomatis untuk silinder besar yang ditenagai oleh rantai daya, dengan kapasitas desain 60 kasus per shift.

(5) Pengujian

Kami memiliki fasilitas inspeksi kelas satu dan test bed untuk memastikan bahwa kinerja silinder memenuhi persyaratan.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding gearbox pertanian. Kami telah mengekspor produk kami ke klien di seluruh dunia dan mendapatkan reputasi yang baik karena kualitas produk dan layanan purna jual kami yang unggul. Kami menyambut pelanggan di dalam dan luar negeri untuk menghubungi kami untuk menegosiasikan bisnis, bertukar informasi, dan bekerja sama dengan kami!

Ikuti Tur Pabrik VR Kami:

Ikuti tur ke pabrik VR kami dengan yang berikut ini

Bagaimana Cara Kerja Silinder Hidrolik Forklift?

Aplikasi Silinder Hidraulik: