Silinder Hidraulik Metalurgi Tipe Pin Tengah

Sebagai salah satu produsen, pemasok, dan eksportir silinder hidrolik, Kami menawarkan silinder hidrolik dan banyak produk lainnya.

Silakan hubungi kami untuk informasi lebih lanjut.

Surat:sales@hydraulic-cylinders.net

Produsen pemasok eksportir silinder hidrolik.

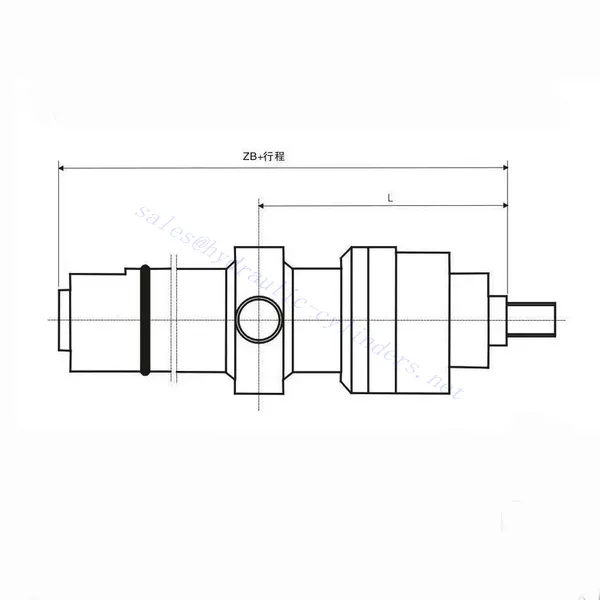

Silinder Hidraulik Metalurgi Tipe Pin Tengah

Medium pin type metallurgical hydraulic cylinder is a cutting-edge hydraulic component designed to meet the strict requirements of metallurgical applications. With superior performance, rugged construction, and innovative design, this hydraulic cylinder provides precise control, durability and efficiency in demanding industrial environments. Whether used in steel mills, foundries, or other metallurgical processes, intermediate pin type cylinders provide outstanding results.

Y-HG1 series of metallurgical equipment hydraulic cylinder for the double acting piston cylinder, cylinder diameter is generally in the range of 40~320mm, the working pressure <=16MPA, the hydraulic oil mechanical system can be used to lose emulsion and other working media, the installation of the flange, earrings, pins, trippers (base) and different types.

High precision CNC honing machine, automatic welding machine, vertical, horizontal machining center, gantry machining center, CNC lathe, and other processing equipment, product quality is stable and guaranteed.

Middle Pin Type Metallurgical Hydraulic Cylinder Parameter:

Silinder Hidraulik Metalurgi Tipe Pin Tengah Usage Method:

- Mounting and Installation:

- According to the specific requirements of metallurgical equipment, determine the appropriate installation position of the hydraulic cylinder.

- Ensure that the mounting surface is clean, flat, and able to withstand the weight and load of the cylinder.

- Connection to Hydraulic System:

- Connect the hydraulic cylinder to the hydraulic system using a compatible hydraulic hose or pipe.

- Ensure proper alignment and secure connections to prevent leaks and ensure optimal performance.

- System Integration and Calibration:

- Integrate hydraulic cylinders into metallurgical equipment or systems by the manufacturer’s guidelines.

- Calibrate the system to achieve desired operating parameters and ensure smooth functioning.

- Operating the Cylinder:

- Start the hydraulic system. Apply pressure to start the movement of the hydraulic cylinder.

- The hydraulic control system controls cylinder extension, contraction, and positioning for efficient metallurgical operations.

Silinder Hidraulik Metalurgi Tipe Pin Tengah Characteristics:

- Middle Pin Design: The unique center pin design provides enhanced stability, precise alignment, and improved load distribution during operation, ensuring optimal performance in metallurgical processes.

- Metallurgical Application Focus: The cylinders are precisely designed to meet the stringent requirements of metallurgical applications, providing reliability and durability under extreme conditions.

- Superior Performance: Cylinders provide excellent performance, enabling accurate positioning, smooth operation, and increased productivity in metallurgical processes.

- Robust Construction: Manufactured from high-quality materials, the cylinders can withstand heavy loads and harsh operating conditions, ensuring long-term durability and reliable performance.

- Safety Features: The design combines overload protection and an emergency shutdown mechanism, prioritizing operator safety in the metallurgical process.

How To Measure Hydraulic Cylinder?

Measuring a hydraulic cylinder is a straightforward process that requires a few essential tools. Here’s a step-by-step guide on how to measure a hydraulic cylinder accurately:

- Gather the Necessary Tools:

- Tape measure or caliper: Use a reliable measuring tool to obtain precise measurements.

- Safety equipment: Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards.

- Determine the Measuring Points:

- Identify the key measuring points on the hydraulic cylinder that will provide the necessary information for accurate measurement.

- The main measuring points typically include the cylinder’s stroke length, bore diameter, and rod diameter.

- Measure the Stroke Length:

- Extend the hydraulic cylinder fully to its maximum length.

- Position the tape measure or caliper at one end of the cylinder, aligning it with the reference point.

- Measure from the reference point to the opposite end of the cylinder.

- Record the size as the stroke length.

- Measure the Bore Diameter:

- Locate the cylinder’s bore, which is the inner diameter of the cylinder tube.

- Position the tape measure or caliper across the bore, ensuring it is perpendicular to the cylinder’s axis.

- Measure one side of the bore from the inner wall to the opposite inner wall.

- Record the measurement as the bore diameter.

- Measure the Rod Diameter:

- Identify the rod, which is the piston rod extending from the hydraulic cylinder.

- Position the tape measure or caliper across the rod’s diameter, perpendicular to its axis.

- Measure one side of the rod, from the outer surface to the opposite outer surface.

- Record the measurement as the rod diameter.

- Additional Measurements:

- Depending on the specific requirements or applications, you may need to measure additional parameters, such as the overall length of the cylinder, the distance between mounting points, or the thread size of the rod.

- Document and Verify Measurements:

- Double-check all recorded measurements to ensure accuracy.

- Document the measurements clearly and organize them for future reference or ordering purposes.

Kemampuan & Kapasitas Pabrik:

(1) Perakitan

Kami memiliki platform perakitan penelitian dan pengembangan independen kelas satu. Bengkel produksi silinder hidrolik memiliki empat jalur perakitan silinder pengangkat semi-otomatis dan satu jalur perakitan silinder kemiringan otomatis, dengan kapasitas produksi tahunan yang dirancang sebesar 1 juta keping. Bengkel silinder khusus dilengkapi dengan berbagai spesifikasi sistem perakitan pembersihan semi-otomatis dengan kapasitas produksi tahunan yang dirancang sebesar 200.000 dan dilengkapi dengan peralatan permesinan CNC yang terkenal, pusat permesinan, peralatan khusus pemrosesan silinder presisi tinggi, mesin las robot, mesin pembersih otomatis, mesin perakitan silinder otomatis, dan jalur produksi pengecatan otomatis. Peralatan penting yang ada lebih dari 300 set (set). Alokasi optimal dan penggunaan sumber daya peralatan yang efisien memastikan persyaratan akurasi produk dan memenuhi kebutuhan produk berkualitas tinggi.

(2) Pemesinan

Bengkel permesinan dilengkapi dengan pusat pembubutan rel miring yang disesuaikan, pusat permesinan, mesin pengasah berkecepatan tinggi, robot pengelasan, dan peralatan terkait lainnya, yang dapat menangani pemrosesan tabung silinder dengan diameter bagian dalam maksimum 400mm dan panjang maksimum 6 meter.

(3) Pengelasan

(4) Pengecatan & pelapisan

Dengan jalur pelapisan cat berbasis air otomatis silinder kecil dan menengah, untuk mencapai bongkar muat robot otomatis dan penyemprotan otomatis, kapasitas desain 4000 buah per shift;

Kami juga memiliki lini produksi cat semi-otomatis untuk silinder besar yang ditenagai oleh rantai daya, dengan kapasitas desain 60 kasus per shift.

(5) Pengujian

Kami memiliki fasilitas inspeksi kelas satu dan test bed untuk memastikan bahwa kinerja silinder memenuhi persyaratan.

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding gearbox pertanian. Kami telah mengekspor produk kami ke klien di seluruh dunia dan mendapatkan reputasi yang baik karena kualitas produk dan layanan purna jual kami yang unggul. Kami menyambut pelanggan di dalam dan luar negeri untuk menghubungi kami untuk menegosiasikan bisnis, bertukar informasi, dan bekerja sama dengan kami!

Ikuti Tur Pabrik VR Kami:

Ikuti tur ke pabrik VR kami dengan yang berikut ini

Bagaimana Cara Kerja Silinder Hidrolik Forklift?

Aplikasi Silinder Hidraulik: