Large Excavator Stick Cylinder

Sebagai salah satu produsen, pemasok, dan eksportir silinder hidrolik, Kami menawarkan silinder hidrolik dan banyak produk lainnya.

Silakan hubungi kami untuk informasi lebih lanjut.

Surat:sales@hydraulic-cylinders.net

Produsen pemasok eksportir silinder hidrolik.

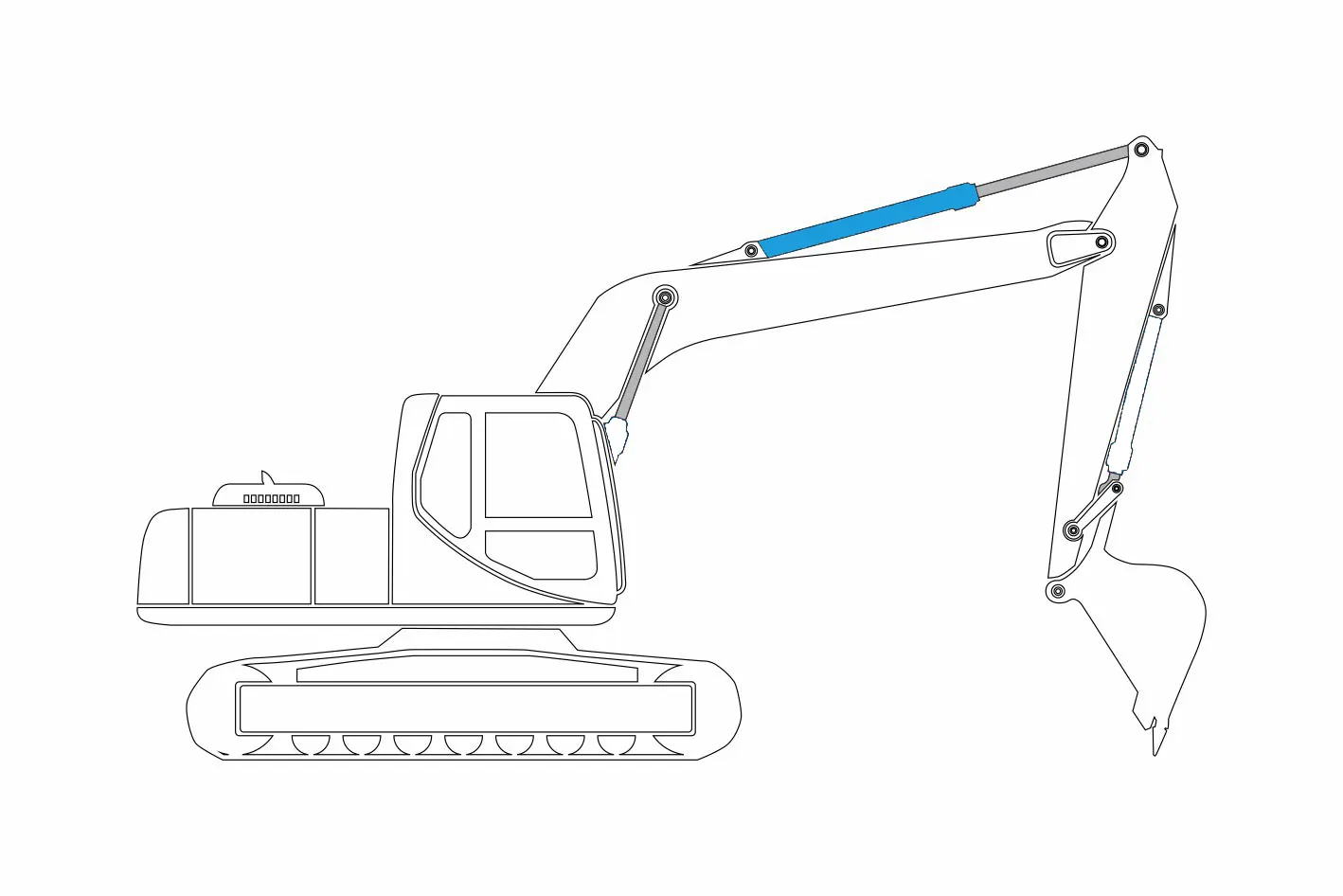

Large Excavator Stick Cylinder

The large excavator stick cylinder is an essential hydraulic component designed to enhance the excavation capabilities of large excavators. This cylinder is vital in extending and retracting the stick, providing optimal control and power for various digging and lifting operations.

The large excavator stick cylinder is a powerful hydraulic component that significantly enhances the excavation capabilities of large excavators. With its robust construction, powerful extension, precise control, and adaptability, this cylinder empowers operators to tackle various excavation tasks easily. Following the recommended usage methods and maintenance practices, operators can ensure optimal performance and longevity of the large excavator stick cylinder, resulting in increased productivity and successful completion of heavy-duty excavation projects. Invest in this exceptional hydraulic cylinder to unlock the full potential of your large excavator and experience superior efficiency and performance in your excavation operations.

Large Excavator Bucket Cylinder Key Characteristics:

- Robust Construction and Durability:

- The large excavator stick cylinder is built with robust materials to withstand rigorous excavation tasks.

- Its durable construction enhances longevity, reducing downtime and maintenance costs.

- Powerful Extension and Retraction:

- This cylinder offers powerful extension and retraction capabilities, enabling the excavator to reach greater depths and maneuver precisely.

- It provides the necessary force to efficiently dig through various soil conditions, increasing productivity on the job site.

- Enhanced Control and Accuracy:

- The large excavator stick cylinder delivers precise control over the stick movement, allowing operators to position and manipulate materials accurately.

- It offers smooth and responsive operation, ensuring seamless digging and lifting operations.

- Adaptability and Compatibility:

- The cylinder is designed to be compatible with a wide range of large excavator models, making it a versatile choice for contractors and operators.

- It can be easily integrated into existing excavator systems, saving time and effort during installation.

Large Excavator Stick Cylinder Parameter:

| Product Name | Large Excavator Stick Cylinder |

| Features: | Control the movement of the forearm |

| Bore diameter: | 210mm~360mm |

| Rod diameter: | 145mm~260mm Stroke≤2600mm |

| Thrust force: | Maximum 3560.8KN |

| Bore diameter: | 360mm/pressure35MPa |

Large Excavator Stick Cylinder Identification Diagram:

Usage Method Of Large Excavator Stick Cylinder:

- Installation and Configuration:

- Follow the manufacturer’s guidelines for proper installation of the large excavator stick cylinder.

- Ensure compatibility and securely attach the cylinder to the excavator’s stick assembly.

- Use the recommended torque specifications and appropriate mounting hardware to establish a reliable connection.

- Operational Considerations:

- Familiarize yourself with the controls and operation of the large excavator, including the stick cylinder.

- Practice operating the excavator and cylinder in a controlled environment before excavating.

- Adhere to safety guidelines and operate within the excavator’s load limits to prevent accidents and equipment damage.

- Optimal Excavation Techniques:

- Utilize the precise control the large excavator stick cylinder offers to optimize excavation performance.

- Extend and retract the stick according to the specific digging requirements, ensuring efficient soil penetration and material handling.

- Adjust the stick angle and height to achieve optimal reach while maintaining stability and balance.

How To Remove Hydraulic Cylinder From Excavator?

Removing a hydraulic cylinder from an excavator requires careful attention and adherence to proper procedures to ensure safety and prevent damage to the equipment. Here are general steps to guide you through the process:

- Preparation:

- Ensure the excavator is turned off and parked on a level surface.

- Engage the safety lock and secure the boom and arm in a stable position.

- Put on appropriate personal protective equipment, such as gloves and safety glasses.

- Identify the Cylinder:

- Locate the hydraulic cylinder you wish to remove. It may be attached to the boom, arm, or other excavator components.

- Relieve Hydraulic Pressure:

- Before disconnecting any hydraulic lines or fittings, it’s crucial to release the pressure in the system to prevent sudden movements or fluid spray.

- Start by locating your excavator model’s pressure relief valve or pressure release procedure.

- Follow the manufacturer’s guidelines to depressurize the hydraulic system properly.

- Disconnect Hydraulic Lines:

- Identify the hydraulic lines connected to the cylinder. These lines carry hydraulic fluid to and from the cylinder.

- Use appropriate wrenches or fittings to loosen and disconnect the hydraulic lines from the cylinder.

- Place a container or absorbent material beneath the disconnected lines to catch residual hydraulic fluid.

- Remove Mounting Hardware:

- Locate the mounting points of the cylinder. These may be bolts or pins securing the cylinder to the excavator’s structure.

- Use the appropriate tools to remove the mounting hardware depending on the specific design.

- Ensure proper support for the cylinder during removal to prevent it from falling or causing damage.

- Detach the Cylinder:

- Carefully slide or maneuver the cylinder out of its mounting position. If it’s tightly fitted, you may need to gently tap it with a rubber mallet or use a hydraulic cylinder puller for assistance.

- Ensure that no other components or structures are obstructing the cylinder’s removal.

- Inspection and Maintenance:

- Once the cylinder is removed, inspect it for any signs of damage, leaks, or wear.

- Clean the cylinder and inspect the rod, seals, and other components for any signs of corrosion, scoring, or excessive wear.

- Perform any necessary maintenance or repairs before reinstalling the cylinder.

- Reinstallation or Replacement:

- To reinstall the hydraulic cylinder, follow the reverse steps of the removal process, ensuring proper alignment and torque specifications.

- If the cylinder is being replaced, carefully install the new cylinder according to the manufacturer’s instructions and guidelines.

Kemampuan & Kapasitas Pabrik:

(1) Perakitan

Kami memiliki platform perakitan penelitian dan pengembangan independen kelas satu. Bengkel produksi silinder hidrolik memiliki empat jalur perakitan silinder pengangkat semi-otomatis dan satu jalur perakitan silinder kemiringan otomatis, dengan kapasitas produksi tahunan yang dirancang sebesar 1 juta keping. Bengkel silinder khusus dilengkapi dengan berbagai spesifikasi sistem perakitan pembersihan semi-otomatis dengan kapasitas produksi tahunan yang dirancang sebesar 200.000 dan dilengkapi dengan peralatan permesinan CNC yang terkenal, pusat permesinan, peralatan khusus pemrosesan silinder presisi tinggi, mesin las robot, mesin pembersih otomatis, mesin perakitan silinder otomatis, dan jalur produksi pengecatan otomatis. Peralatan penting yang ada lebih dari 300 set (set). Alokasi optimal dan penggunaan sumber daya peralatan yang efisien memastikan persyaratan akurasi produk dan memenuhi kebutuhan produk berkualitas tinggi.

(2) Pemesinan

Bengkel permesinan dilengkapi dengan pusat pembubutan rel miring yang disesuaikan, pusat permesinan, mesin pengasah berkecepatan tinggi, robot pengelasan, dan peralatan terkait lainnya, yang dapat menangani pemrosesan tabung silinder dengan diameter bagian dalam maksimum 400mm dan panjang maksimum 6 meter.

(3) Pengelasan

(4) Pengecatan & pelapisan

Dengan jalur pelapisan cat berbasis air otomatis silinder kecil dan menengah, untuk mencapai bongkar muat robot otomatis dan penyemprotan otomatis, kapasitas desain 4000 buah per shift;

Kami juga memiliki lini produksi cat semi-otomatis untuk silinder besar yang ditenagai oleh rantai daya, dengan kapasitas desain 60 kasus per shift.

(5) Pengujian

Kami memiliki fasilitas inspeksi kelas satu dan test bed untuk memastikan bahwa kinerja silinder memenuhi persyaratan.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding gearbox pertanian. Kami telah mengekspor produk kami ke klien di seluruh dunia dan mendapatkan reputasi yang baik karena kualitas produk dan layanan purna jual kami yang unggul. Kami menyambut pelanggan di dalam dan luar negeri untuk menghubungi kami untuk menegosiasikan bisnis, bertukar informasi, dan bekerja sama dengan kami!

Ikuti Tur Pabrik VR Kami:

Ikuti tur ke pabrik VR kami dengan yang berikut ini

Bagaimana Cara Kerja Silinder Hidrolik Forklift?

Aplikasi Silinder Hidraulik: