Double Shield TBM Support Shoe Cylinder

Sebagai salah satu produsen, pemasok, dan eksportir silinder hidrolik, Kami menawarkan silinder hidrolik dan banyak produk lainnya.

Silakan hubungi kami untuk informasi lebih lanjut.

Surat:sales@hydraulic-cylinders.net

Produsen pemasok eksportir silinder hidrolik.

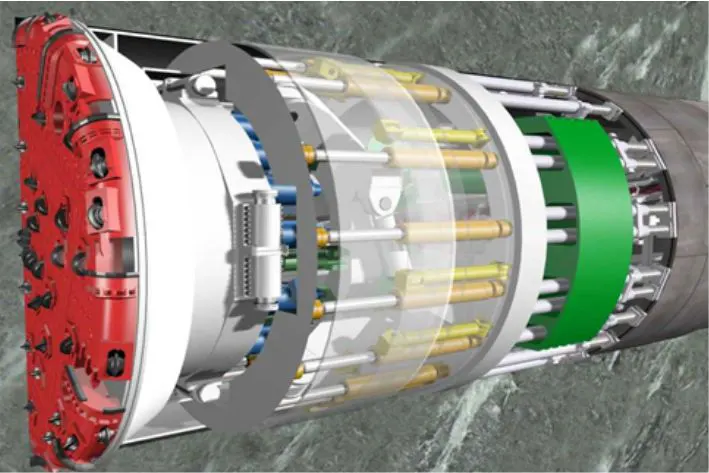

Double Shield TBM Support Shoe Cylinder

The double shield TBM support shoe cylinder is a cutting-edge hydraulic component designed to enhance tunnel boring operations’ efficiency and safety. This specialized cylinder plays a crucial role in supporting the shield of a double-shield tunnel boring machine (TBM), ensuring stability and protection during excavation. This informative article will explore the key characteristics, usage methods, and maintenance guidelines for the double shield tbm support shoe cylinder.

The double shield TBM support shoe cylinder is a vital component that enhances the efficiency and safety of double shield tunnel boring operations. With its improved stability, precise control, dual-acting design, durability, and reliability, this cylinder ensures secure support and protection of the TBM shield during excavation. By following the recommended usage methods and adhering to regular maintenance practices, the double shield tbm support shoe cylinder will continue to deliver outstanding performance, contributing to the success of tunneling projects. Experience the efficiency and safety of the double shield tbm support shoe cylinder, revolutionizing tunnel boring operations with advanced technology and reliability.

Double Shield TBM Support Shoe Cylinder Key Characteristics:

- Enhanced Stability and Load Bearing: The double shield TBM support shoe cylinder is engineered to provide exceptional stability and load-bearing capacity to the TBM shield. Its robust construction and precise engineering ensure that the shield remains securely in place during excavation, minimizing the risk of ground collapse and ensuring the safety of the tunneling crew.

- Precise Control and Positioning: Equipped with advanced hydraulic control systems, this cylinder offers precise control over the positioning of the support shoes. This allows operators to adjust the shoe’s orientation and alignment to match the specific ground conditions, ensuring accurate and efficient excavation.

- Dual-Acting Design: The double shield tbm support shoe cylinder features a dual-acting design, which means it can exert force in both the extension and retraction directions. This capability allows for versatile and controlled movement of the support shoes, providing optimal support and stability during the tunneling process.

- Durability and Reliability: Built with high-quality materials, the double shield tbm support shoe cylinder is designed to withstand the demanding conditions encountered during tunneling operations. It can withstand heavy loads, vibrations, and shocks, providing long-term durability, minimizing downtime, and reducing maintenance costs.

Double Shield TBM Support Shoe Cylinder Parameter:

| Product Name | Double Shield Tunnel Boring Machine Support Shoe Cylinder |

| Features: | Provides the thrust of cutterhead tunneling |

| Bore diameter: | 320mm~700mm |

| Rod diameter: | 220mm~500mm Stroke: 300mm~1200mm |

| Pressure: | up to 35MPa |

| Applications: | Double Shield Tunnel Boring Machine |

Double Shield TBM Cylinder Application:

Usage Method Of Double Shield TBM Support Shoe Cylinder:

- Cylinder Installation: Install the double shield tbm support shoe cylinder according to the manufacturer’s instructions. Use suitable mounting brackets or accessories to ensure proper alignment and secure attachment to the TBM’s support shoe structure.

- Hydraulic System Integration: Connect the cylinder to the TBM’s hydraulic system using compatible hoses and fittings. Verify that all connections are secure, leak-free, and adequately tightened to ensure optimal hydraulic performance.

- Control and Positioning: Familiarize yourself with the rules specific to the double shield tbm support shoe cylinder. Use these controls to adjust the support shoes’ position, alignment, and angle as necessary. Follow the TBM manufacturer’s guidelines and recommendations for optimal support shoe positioning based on the ground conditions.

- Safety Precautions: Adhere to all safety protocols and guidelines provided by the TBM manufacturer. Ensure that operators are trained in the safe operation of the tbm and the double shield tbm support shoe cylinder. Regularly inspect safety mechanisms and perform maintenance as recommended to ensure proper functioning.

How To Build A Hydraulic Cylinder?

Building a hydraulic cylinder requires advanced engineering knowledge, specialized equipment, and access to high-quality materials. Due to the complexity and precision involved, it is typically a task undertaken by professional manufacturers. However, here is a general overview of the steps involved in building a hydraulic cylinder:

- Design and Engineering:

- Determine the specific requirements and specifications of the hydraulic cylinder, such as stroke length, bore diameter, operating pressure, and load capacity.

- Use computer-aided design (CAD) software to create a detailed plan that includes the cylinder’s dimensions, internal components, and seals.

- Material Selection:

- Choose high-quality materials for hydraulic applications, such as steel or aluminum for the cylinder barrel, piston, and end caps.

- Select appropriate seals, such as O-rings or piston seals, that can withstand the operating conditions and fluid compatibility.

- Machining:

- Use precision machining equipment, such as lathes, mills, and grinders, to fabricate the cylinder components according to the design specifications.

- Machine the cylinder barrel, end caps, piston, rod, and other internal components to the required dimensions and tolerances.

- Assembly:

- Clean all components thoroughly to remove any contaminants or debris.

- Install seals into the designated grooves on the piston, end caps, and rod.

- Carefully insert the piston into the cylinder barrel, ensuring proper alignment and clearance.

- Attach the end caps to the cylinder barrel, ensuring a secure and leak-free connection.

- Insert the rod into the piston and secure it with appropriate fasteners.

- Attach hydraulic fittings or ports to the end caps for fluid connections.

- Testing and Quality Control:

- Conduct pressure testing to ensure the cylinder can withstand the specified operating pressure without leaks or failures.

- Verify the proper functioning of the cylinder by extending and retracting it under controlled conditions.

- Inspect all components for defects or imperfections, ensuring they meet the required specifications.

- Perform quality control checks to ensure the cylinder meets safety and regulatory requirements.

Kemampuan & Kapasitas Pabrik:

(1) Perakitan

Kami memiliki platform perakitan penelitian dan pengembangan independen kelas satu. Bengkel produksi silinder hidrolik memiliki empat jalur perakitan silinder pengangkat semi-otomatis dan satu jalur perakitan silinder kemiringan otomatis, dengan kapasitas produksi tahunan yang dirancang sebesar 1 juta keping. Bengkel silinder khusus dilengkapi dengan berbagai spesifikasi sistem perakitan pembersihan semi-otomatis dengan kapasitas produksi tahunan yang dirancang sebesar 200.000 dan dilengkapi dengan peralatan permesinan CNC yang terkenal, pusat permesinan, peralatan khusus pemrosesan silinder presisi tinggi, mesin las robot, mesin pembersih otomatis, mesin perakitan silinder otomatis, dan jalur produksi pengecatan otomatis. Peralatan penting yang ada lebih dari 300 set (set). Alokasi optimal dan penggunaan sumber daya peralatan yang efisien memastikan persyaratan akurasi produk dan memenuhi kebutuhan produk berkualitas tinggi.

(2) Pemesinan

Bengkel permesinan dilengkapi dengan pusat pembubutan rel miring yang disesuaikan, pusat permesinan, mesin pengasah berkecepatan tinggi, robot pengelasan, dan peralatan terkait lainnya, yang dapat menangani pemrosesan tabung silinder dengan diameter bagian dalam maksimum 400mm dan panjang maksimum 6 meter.

(3) Pengelasan

(4) Pengecatan & pelapisan

Dengan jalur pelapisan cat berbasis air otomatis silinder kecil dan menengah, untuk mencapai bongkar muat robot otomatis dan penyemprotan otomatis, kapasitas desain 4000 buah per shift;

Kami juga memiliki lini produksi cat semi-otomatis untuk silinder besar yang ditenagai oleh rantai daya, dengan kapasitas desain 60 kasus per shift.

(5) Pengujian

Kami memiliki fasilitas inspeksi kelas satu dan test bed untuk memastikan bahwa kinerja silinder memenuhi persyaratan.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding gearbox pertanian. Kami telah mengekspor produk kami ke klien di seluruh dunia dan mendapatkan reputasi yang baik karena kualitas produk dan layanan purna jual kami yang unggul. Kami menyambut pelanggan di dalam dan luar negeri untuk menghubungi kami untuk menegosiasikan bisnis, bertukar informasi, dan bekerja sama dengan kami!

Ikuti Tur Pabrik VR Kami:

Ikuti tur ke pabrik VR kami dengan yang berikut ini

Bagaimana Cara Kerja Silinder Hidrolik Forklift?

Aplikasi Silinder Hidraulik: