3KW With Cooling Fan Standard Hydraulic Power Unit Pack

Sebagai salah satu produsen, pemasok, dan eksportir silinder hidrolik, Kami menawarkan silinder hidrolik dan banyak produk lainnya.

Silakan hubungi kami untuk informasi lebih lanjut.

Surat:sales@hydraulic-cylinders.net

Produsen pemasok eksportir silinder hidrolik.

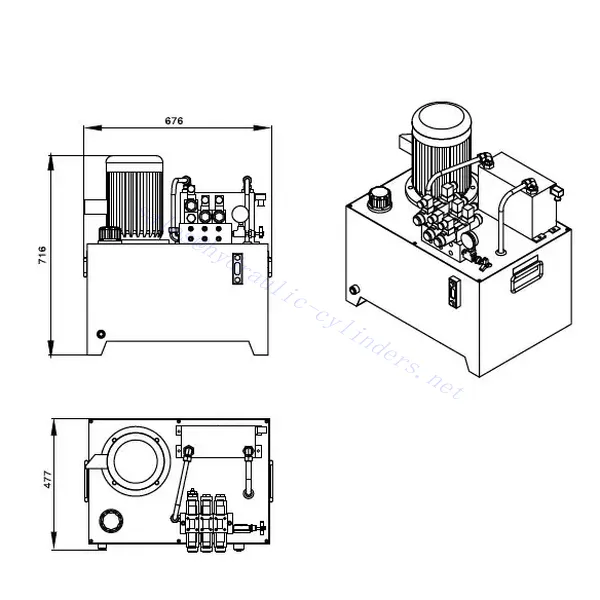

3KW With Cooling Fan Standard Hydraulic Power Unit Pack

The 3KW standard hydraulic power unit package with a cooling fan is a cutting-edge solution designed to deliver superior power and efficiency for a wide range of industrial applications. This hydraulic power unit offers a powerful 3KW motor, an integrated cooling fan, and a standard configuration that ensures optimal performance, reliable cooling, and ease of use. From machine tools to material handling equipment, the 3KW standard hydraulic power unit package with a cooling fan provides consistent power delivery, efficient cooling, and increased productivity.

Standard Hydraulic Power Unit Packs Model Description:

3KW With Cooling Fan Standard Hydraulic Power Unit Pack Parameter:

Standard Hydraulic Power Unit Packs Specification:

Standard Hydraulic Power Unit Packs Optional Parts:

Standard Hydraulic Power Unit Packs Schematic Diagram:

Standard Hydraulic Power Unit Packs Maintenance:

Regular Inspections:

- Perform routine inspections to identify any signs of leakage, damage, or wear in the 3KW cooling fan standard hydraulic power unit package.

- Inspect hydraulic hoses, fittings, and seals to ensure they function correctly and replace worn or damaged parts.

Cooling Fan Maintenance:

- Keep the cooling fan clean and debris-free to ensure the best heat dissipation effect.

- Check the fan blades regularly for damage or blockage, and clean them if necessary.

Fluid Level Check:

- Regularly monitor and maintain the hydraulic fluid level within the recommended operating range.

- Check hydraulic oil for signs of contamination or degradation and replace it if necessary.

Filter Maintenance:

- Clean or replace hydraulic filters as recommended by the manufacturer.

- Check the filter regularly for signs of blockage or damage that could affect the performance of the power unit.

How Does A One Way Hydraulic Cylinder Work?

A one-way, single-acting hydraulic cylinder uses a hydraulic system to generate linear motion in one direction. It consists of a cylinder barrel, piston, piston rod, and hydraulic fluid. Here’s how it works:

- Hydraulic Fluid Supply:

- The hydraulic system supplies pressurized fluid, typically oil, to the cylinder through a hydraulic pump or power source.

- Cylinder Extension:

- When hydraulic fluid is supplied to the cylinder, it enters the cylinder barrel through an inlet port.

- The pressurized fluid pushes against the piston, causing it to move in the desired direction (typically extending the piston rod).

- As the fluid pressure increases, it overcomes the resistance or load on the piston, resulting in the extension of the piston rod.

- Sealing Mechanism:

- The cylinder barrel is sealed to prevent fluid leakage. It typically incorporates seals around the piston and piston rod, such as O-rings or lip seals.

- These seals ensure that the pressurized fluid acts only on one side of the piston, creating a pressure imbalance that drives the piston in the desired direction.

- Return Stroke:

- After the extension stroke, the hydraulic fluid is released or vented from the cylinder.

- The hydraulic system may use gravity, a spring, or an external force to retract the piston and piston rod to their initial positions.

- During the return stroke, the hydraulic fluid flows out of the cylinder through an outlet port.

- Load Support:

- The piston rod of the hydraulic cylinder is often connected to a load or mechanism that requires linear motion or force.

- As the piston extends or retracts, it provides the necessary force to move or support the load.

- Control and Valves:

- To control the extension and retraction of the one-way hydraulic cylinder, the hydraulic system incorporates valves, such as check valves or directional control valves.

- These valves regulate the flow of hydraulic fluid, allowing it to enter and exit the cylinder in the desired direction.

- Application Specifics:

- One-way hydraulic cylinders are commonly used in applications where force or motion is required in only one direction, such as lifting, pushing, or clamping.

- They are often found in hydraulic jacks, hydraulic presses, dump trucks, and various other industrial and mobile equipment.

Kemampuan & Kapasitas Pabrik:

(1) Perakitan

Kami memiliki platform perakitan penelitian dan pengembangan independen kelas satu. Bengkel produksi silinder hidrolik memiliki empat jalur perakitan silinder pengangkat semi-otomatis dan satu jalur perakitan silinder kemiringan otomatis, dengan kapasitas produksi tahunan yang dirancang sebesar 1 juta keping. Bengkel silinder khusus dilengkapi dengan berbagai spesifikasi sistem perakitan pembersihan semi-otomatis dengan kapasitas produksi tahunan yang dirancang sebesar 200.000 dan dilengkapi dengan peralatan permesinan CNC yang terkenal, pusat permesinan, peralatan khusus pemrosesan silinder presisi tinggi, mesin las robot, mesin pembersih otomatis, mesin perakitan silinder otomatis, dan jalur produksi pengecatan otomatis. Peralatan penting yang ada lebih dari 300 set (set). Alokasi optimal dan penggunaan sumber daya peralatan yang efisien memastikan persyaratan akurasi produk dan memenuhi kebutuhan produk berkualitas tinggi.

(2) Pemesinan

Bengkel permesinan dilengkapi dengan pusat pembubutan rel miring yang disesuaikan, pusat permesinan, mesin pengasah berkecepatan tinggi, robot pengelasan, dan peralatan terkait lainnya, yang dapat menangani pemrosesan tabung silinder dengan diameter bagian dalam maksimum 400mm dan panjang maksimum 6 meter.

(3) Pengelasan

(4) Pengecatan & pelapisan

Dengan jalur pelapisan cat berbasis air otomatis silinder kecil dan menengah, untuk mencapai bongkar muat robot otomatis dan penyemprotan otomatis, kapasitas desain 4000 buah per shift;

Kami juga memiliki lini produksi cat semi-otomatis untuk silinder besar yang ditenagai oleh rantai daya, dengan kapasitas desain 60 kasus per shift.

(5) Pengujian

Kami memiliki fasilitas inspeksi kelas satu dan test bed untuk memastikan bahwa kinerja silinder memenuhi persyaratan.

We are one of the best hydraulic power unit pack manufacturers. We can offer comprehensive hydraulic power unit pack stock. We also provide corresponding gearbox pertanian. Kami telah mengekspor produk kami ke klien di seluruh dunia dan mendapatkan reputasi yang baik karena kualitas produk dan layanan purna jual kami yang unggul. Kami menyambut pelanggan di dalam dan luar negeri untuk menghubungi kami untuk menegosiasikan bisnis, bertukar informasi, dan bekerja sama dengan kami!

Ikuti Tur Pabrik VR Kami:

Ikuti tur ke pabrik VR kami dengan yang berikut ini

Bagaimana Cara Kerja Silinder Hidrolik Forklift?

Aplikasi Silinder Hidraulik: