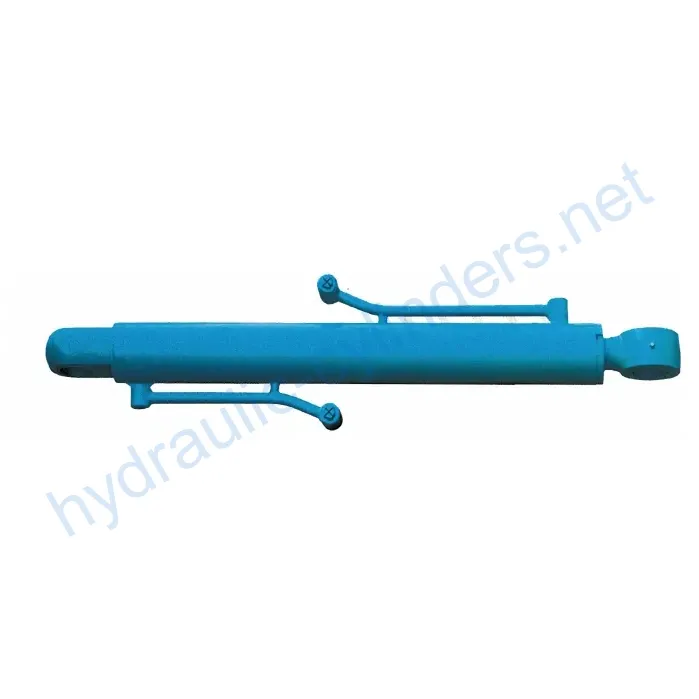

Bucket Cylinder For Bada WYS40

Mint a hidraulikus hengerek egyik gyártója, szállítója és exportőre a mechanikai termékek, kínálunk hidraulikus hengerek és sok más termék.

Kérjük, lépjen kapcsolatba velünk a részletekért.

Posta:sales@hydraulic-cylinders.net

Hidraulikus hengerek gyártója, szállítója és exportőre.

Bucket Cylinder For Bada WYS40

Introduction

The bucket cylinder is a specialized hydraulic cylinder designed for controlling the movement of the bucket in heavy machinery such as excavators, backhoe excavators, and front-end loaders. Its primary function is to enable the bucket to lift, lower, and tilt, making it easier to handle various material handling tasks. In the hydraulic system, the bucket cylinder uses the pressure change of the hydraulic oil to precisely control the bucket, allowing operators to efficiently handle heavy loads and adapt to complex work environments and diverse job requirements.

Features

- High Strength and Durability: Typically made of high-strength steel or aluminum, it can withstand high pressure and heavy loads, adapt to harsh working environments, and design for wear resistance and corrosion resistance to extend service life.

- Efficient Hydraulic Operations: Using the pressure of hydraulic oil to achieve smooth expansion and contraction, it can quickly respond to control commands, provide powerful pushing and pulling forces, and is suitable for handling heavy loads and complex job tasks.

- Various Types: Single-acting (hydraulic only used in one direction) or double-acting (hydraulic used in both directions) cylinders can be selected according to needs to meet different operating requirements. Some models are telescopic, allowing greater extension without increasing external dimensions, suitable for applications with limited space.

- Can be used as a replacement for other hydraulic cylinders.

- Easy to install and maintain.

Applications

The bucket cylinder is widely used in various heavy machinery, including:

- Construction Equipment: In excavators, they are essential for excavation, loading, and moving soil or debris. In backhoe excavators, the bucket cylinder helps with both excavation and lifting.

- Agricultural machinery: Used in front-end loaders for scooping, lifting, and transporting soil, hay, and other materials.

- Excavators: Bucket cylinders achieve excavation actions by allowing buckets to penetrate the soil.

- Loaders: In front-end loaders, they help with lifting and dumping goods efficiently.

Each application of the cylinder is described in detail below:

Construction Equipment

Bucket cylinders play a crucial role in excavators, as they are responsible for digging, scooping, and moving soil and debris. They allow excavators to complete their work efficiently and handle even the most challenging excavations. Backhoe excavators also use bucket cylinders to help with excavation and lifting. In these machines, the cylinder is instrumental in controlling the movement and position of the bucket, allowing operators to achieve precise results.

Agricultural Machinery

Bucket cylinders are used in front-end loaders for scooping, lifting, and transporting soil, hay, and other materials. The cylinder allows the loader to complete these tasks efficiently and with great precision. By controlling the position and movement of the bucket, the cylinder enables the loader to lift and transport even the heaviest loads.

Excavators

In excavators, the bucket cylinder allows the bucket to penetrate the soil to achieve excavation actions. The cylinder controls the movement and position of the bucket, allowing operators to achieve precise results. Excavators are used in a wide range of applications, including mining, construction, and demolition.

Loaders

Front-end loaders use bucket cylinders to help with lifting and dumping goods efficiently. By controlling the movement and position of the bucket, the cylinder allows the loader to handle heavy loads with ease. Loaders are used in a wide range of applications, including agriculture, construction, and mining.

Design Considerations and Selection Criteria

When designing bucket cylinders, factors such as load capacity, sealing, durability, safety, and maintainability must be considered. Below are the design considerations:

- Load Capacity: The cylinder should be designed to withstand the maximum load that it will be subjected to.

- Sealing: High-quality sealing materials should be used to prevent leakage of hydraulic fluid and ensure smooth operation.

- Durability: The cylinder should be designed to withstand the harsh working environment and minimize wear and tear.

- Safety: The cylinder should be designed to ensure operator safety and prevent accidents.

- Maintainability: The cylinder should be easy to maintain, with replaceable parts and clear instructions for maintenance procedures.

Sealing and Lubrication

Various seals, such as piston seals and rod seals, should be used to ensure the cylinder’s sealing. The seals should be made of wear-resistant materials such as polyurethane and nitrile rubber to ensure a long service life. The cylinder should be designed with a finely processed cylinder body and thread end surface to improve wear resistance. Regular lubrication with hydraulic oil is necessary to ensure smooth operation and extend the cylinder’s life.

Maintenance and Repair

Regular maintenance and repair are required to ensure the cylinder’s proper functioning and extend its lifespan. Common maintenance tasks include regular inspection, appropriate lubrication, seal replacement, and calibration checks. Proper installation, lubrication, and adjustment are essential to ensure the cylinder’s correct functioning. It is recommended to use appropriate installation brackets to secure the cylinder. Recommended inspection, repair, and replacement procedures should be followed, and rebuild services should be used, if necessary, to improve the cylinder’s lifespan.

Safety and Environmental Considerations

When using the bucket cylinder, safety measures should be taken to prevent accidents. It is essential to follow the manufacturer’s instructions and ensure that the cylinder is installed correctly, maintained regularly, and inspected frequently. Handling the cylinder with care and wearing protective gear can help prevent accidents. Environmental factors should also be considered when using the cylinder. Proper disposal of hydraulic oil and other hazardous materials is necessary to minimize the impact on the environment.

Fault Diagnosis and Troubleshooting

Common problems with the bucket cylinder include leakage, slow or unresponsive movement, and abnormal noise. To diagnose and troubleshoot these issues, it is necessary to inspect the cylinder regularly and use appropriate tools to identify the issue. Regular maintenance and repair can help prevent these problems from occurring.

Company Introduction

We are a manufacturer of replacement hydraulic cylinders, offering a comprehensive range of products and services to meet the diverse needs of our customers. With a focus on excellent quality, we rely on a refined manufacturing workshop and industrialized production management strategies to constantly improve our manufacturing platform and perfect our product quality production line. We have a strong ability to create high-efficiency, high-precision, and high-quality products, meeting the diverse needs of our customers.

Our company is characterized by:

- Professionalism: We have a team of highly skilled professionals who are experts in hydraulic cylinder design and production.

- International Certification: Our products have been certified by various international organizations, ensuring their quality and safety.

- Customization Services: We provide customized services to meet the specific needs of our customers.

- Production Equipment: We have advanced manufacturing equipment and testing systems to ensure the quality of our products.

- After-sales Service: We provide comprehensive after-sales service, including maintenance, repair, and replacement services.

We are committed to providing our customers with the best products and services, and we strive to improve our manufacturing capabilities and product quality continuously. Our goal is to become a leading hydraulic cylinder manufacturer and wholesaler in the domestic and international markets.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: