3KW With Cooling Fan Standard Hydraulic Power Unit Pack

Mint a hidraulikus hengerek egyik gyártója, szállítója és exportőre a mechanikai termékek, kínálunk hidraulikus hengerek és sok más termék.

Kérjük, lépjen kapcsolatba velünk a részletekért.

Posta:sales@hydraulic-cylinders.net

Hidraulikus hengerek gyártója, szállítója és exportőre.

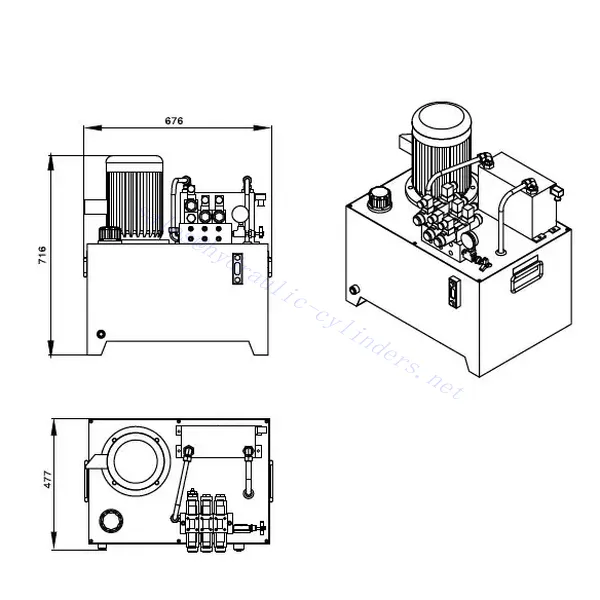

3KW With Cooling Fan Standard Hydraulic Power Unit Pack

The 3KW standard hydraulic power unit package with a cooling fan is a cutting-edge solution designed to deliver superior power and efficiency for a wide range of industrial applications. This hydraulic power unit offers a powerful 3KW motor, an integrated cooling fan, and a standard configuration that ensures optimal performance, reliable cooling, and ease of use. From machine tools to material handling equipment, the 3KW standard hydraulic power unit package with a cooling fan provides consistent power delivery, efficient cooling, and increased productivity.

Standard Hydraulic Power Unit Packs Model Description:

3KW With Cooling Fan Standard Hydraulic Power Unit Pack Parameter:

Standard Hydraulic Power Unit Packs Specification:

Standard Hydraulic Power Unit Packs Optional Parts:

Standard Hydraulic Power Unit Packs Schematic Diagram:

Standard Hydraulic Power Unit Packs Karbantartás:

Regular Inspections:

- Perform routine inspections to identify any signs of leakage, damage, or wear in the 3KW cooling fan standard hydraulic power unit package.

- Inspect hydraulic hoses, fittings, and seals to ensure they function correctly and replace worn or damaged parts.

Cooling Fan Maintenance:

- Keep the cooling fan clean and debris-free to ensure the best heat dissipation effect.

- Check the fan blades regularly for damage or blockage, and clean them if necessary.

Fluid Level Check:

- Regularly monitor and maintain the hydraulic fluid level within the recommended operating range.

- Check hydraulic oil for signs of contamination or degradation and replace it if necessary.

Filter Maintenance:

- Clean or replace hydraulic filters as recommended by the manufacturer.

- Check the filter regularly for signs of blockage or damage that could affect the performance of the power unit.

How Does A One Way Hydraulic Cylinder Work?

A one-way, single-acting hydraulic cylinder uses a hydraulic system to generate linear motion in one direction. It consists of a cylinder barrel, piston, piston rod, and hydraulic fluid. Here’s how it works:

- Hydraulic Fluid Supply:

- The hydraulic system supplies pressurized fluid, typically oil, to the cylinder through a hydraulic pump or power source.

- Cylinder Extension:

- When hydraulic fluid is supplied to the cylinder, it enters the cylinder barrel through an inlet port.

- The pressurized fluid pushes against the piston, causing it to move in the desired direction (typically extending the piston rod).

- As the fluid pressure increases, it overcomes the resistance or load on the piston, resulting in the extension of the piston rod.

- Sealing Mechanism:

- The cylinder barrel is sealed to prevent fluid leakage. It typically incorporates seals around the piston and piston rod, such as O-rings or lip seals.

- These seals ensure that the pressurized fluid acts only on one side of the piston, creating a pressure imbalance that drives the piston in the desired direction.

- Return Stroke:

- After the extension stroke, the hydraulic fluid is released or vented from the cylinder.

- The hydraulic system may use gravity, a spring, or an external force to retract the piston and piston rod to their initial positions.

- During the return stroke, the hydraulic fluid flows out of the cylinder through an outlet port.

- Load Support:

- The piston rod of the hydraulic cylinder is often connected to a load or mechanism that requires linear motion or force.

- As the piston extends or retracts, it provides the necessary force to move or support the load.

- Control and Valves:

- To control the extension and retraction of the one-way hydraulic cylinder, the hydraulic system incorporates valves, such as check valves or directional control valves.

- These valves regulate the flow of hydraulic fluid, allowing it to enter and exit the cylinder in the desired direction.

- Application Specifics:

- One-way hydraulic cylinders are commonly used in applications where force or motion is required in only one direction, such as lifting, pushing, or clamping.

- They are often found in hydraulic jacks, hydraulic presses, dump trucks, and various other industrial and mobile equipment.

A gyár kapacitása és kapacitása:

(1) Összeszerelés

Első osztályú független kutatási és fejlesztési összeszerelési platformmal rendelkezünk. A hidraulikus hengergyártó műhely négy félautomata emelőhenger-összeszerelő sorral és egy automata billenőhenger-összeszerelő sorral rendelkezik, tervezett éves gyártási kapacitása 1 millió darab. A speciális henger műhely különböző specifikációjú félautomata tisztító összeszerelő rendszerrel van felszerelve, amelynek tervezett éves termelési kapacitása 200.000, és híres CNC megmunkáló berendezéssel, megmunkáló központtal, nagy pontosságú hengerfeldolgozó speciális berendezéssel, robothegesztő géppel, automatikus tisztítógéppel, automatikus henger összeszerelő géppel és automatikus festési gyártósorral van felszerelve. A meglévő kritikus berendezések több mint 300 készlet (készlet). A berendezések erőforrásainak optimális elosztása és hatékony felhasználása biztosítja a termékek pontossági követelményeit és megfelel a termékek minőségi igényeinek.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic power unit pack manufacturers. We can offer comprehensive hydraulic power unit pack stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: