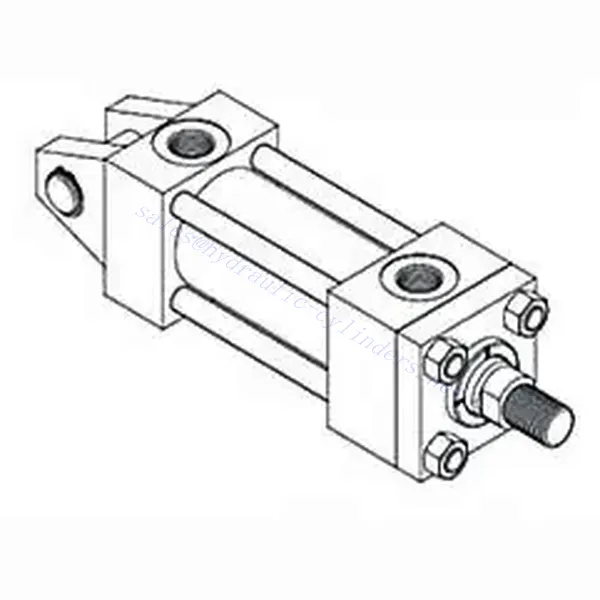

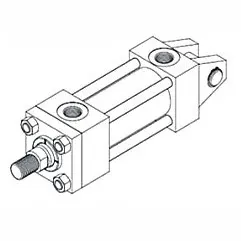

Rear Double Earring Four Rod Hydraulic Cylinder

En tant que fabricant, fournisseur et exportateur de produits mécaniques, nous proposons des vérins hydrauliques et de nombreux autres produits.

N'hésitez pas à nous contacter pour plus de détails.

Courrier :sales@hydraulic-cylinders.net

Fabricant fournisseur exportateur de vérins hydrauliques.

Rear Double Earring Four Rod Hydraulic Cylinder

The rear double earring four rod hydraulic cylinder is an advanced hydraulic component that provides exceptional performance and reliability in various industrial applications. With its innovative rear double earring and four rod configuration, this four rod hydraulic cylinder offers precise and efficient linear motion control, making it an ideal choice for demanding tasks.

Essential Characteristics Of Four Rod Hydraulic Cylinder:

Rear Double Earring Design:

- The four rod hydraulic cylinder features a rear double earring design, providing a secure and stable mounting solution.

- The rear double earring enhances the cylinder’s structural integrity, ensuring reliable operation even under heavy loads and extreme conditions.

- Four Rod Configuration:

- The four rod configuration of this hydraulic cylinder enhances stability and load distribution.

- The rods work in tandem to prevent deflection, resulting in precise and consistent linear motion control.

- High Performance:

- The rear double earring four rod hydraulic cylinder delivers exceptional performance, high force output, and smooth operation.

- It provides precise control of linear motion, allowing precise positioning and efficient operation in a variety of industrial applications.

- Robust Construction:

- This four rod hydraulic cylinder is built with high-quality materials, ensuring durability and long-lasting performance.

- The robust construction enables the cylinder to withstand heavy loads, high pressures, and harsh operating conditions.

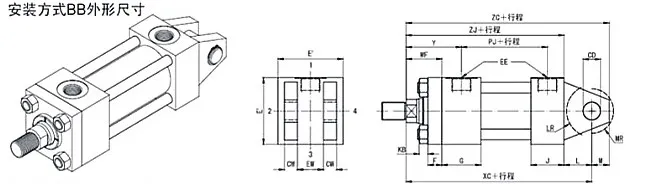

Rear Double Earring Four Rod Hydraulic Cylinder Parameter:

Rear Double Earring Four Rod Hydraulic Cylinder Usage Method:

Mounting and Installation:

- Determine the appropriate location to install hydraulic cylinders in the system or equipment.

- Ensure the installation surface is clean and free of debris or contaminants.

- Place the rear single earring flush with the mounting face and secure it with recommended bolts or fasteners.

Hydraulic Connections:

- Connect hydraulic supply line to cylinder port, ensuring proper seal to prevent leakage.

- Follow the manufacturer’s recommendations for hydraulic fluid type and fill the system accordingly.

Operation:

- Activate the hydraulic system and control the cylinder’s movement using a hydraulic control valve.

- Adjust the flow and pressure settings to achieve the desired speed and force output.

- Monitor the cylinder’s operation for any irregularities or signs of malfunction.

Rear Double Earring Four Rod Hydraulic Cylinder Maintenance:

Regular Inspection:

- Perform a routine visual inspection to check for any signs of wear, leakage, or damage.

- Check seals, tie rods, cylinder blocks, etc. for abnormalities, and replace worn or damaged parts in time.

Lubrication:

- Follow the manufacturer’s lubrication interval guidelines and use recommended lubricants to ensure smooth operation.

- Lubricate rods, seals, and other moving parts to prevent friction and extend cylinder life.

Sealing System Maintenance:

- Make sure the sealing system is in good condition to prevent leaks and maintain optimum performance.

- Check seals regularly for wear or damage and replace them if necessary.

- Clean sealing surfaces and ensure they are properly aligned when reassembled.

How Much Does It Cost To Rebuild A Hydraulic Cylinder?

The cost of rebuilding a hydraulic cylinder can vary depending on several factors, including the size of the cylinder, the extent of the damage or wear, the availability of replacement parts, and the labor costs involved. It’s difficult to provide an exact cost without specific details about the cylinder.

In general, the cost to rebuild a hydraulic cylinder typically includes:

- Replacement Parts:

- Seals, o-rings, and other wear components.

- Pistons, rods, or other damaged internal parts if necessary.

- Labor:

- Disassembly and inspection of the cylinder.

- Cleaning and preparation of the components.

- Replacement of damaged or worn parts.

- Reassembly and testing.

- Additional Services:

- Machining or honing of cylinder surfaces if needed.

- Surface treatment or coating to enhance durability.

- Hydraulic fluid or lubricant replacement.

Capacité de l'usine :

(1) Assemblage

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Usinage

L'atelier d'usinage est équipé d'un centre de tournage sur rail incliné personnalisé, d'un centre d'usinage, d'une machine à honer à grande vitesse, d'un robot de soudage et d'autres équipements connexes, qui peuvent traiter des tubes cylindriques d'un diamètre intérieur maximal de 400 mm et d'une longueur maximale de 6 mètres.

(3) Soudage

(4) Peinture et revêtement

Avec des lignes de revêtement de peinture à base d'eau automatiques à cylindre de petite et moyenne taille, pour réaliser le chargement et le déchargement automatiques par robot et la pulvérisation automatique, la capacité de conception est de 4 000 pièces par équipe ;

Nous disposons également d'une ligne de production de peinture semi-automatique pour gros cylindres, alimentée par une chaîne de traction, d'une capacité de conception de 60 caisses par équipe.

(5) Essais

Nous disposons d'installations d'inspection et de bancs d'essai de premier ordre pour garantir que les performances de la bouteille sont conformes aux exigences.

We are one of the best light four rod hydraulic cylinder manufacturers. We can offer comprehensive light four rod hydraulic cylinder stock. We also provide corresponding boîtes de vitesses agricoles. Nous avons exporté nos produits vers des clients du monde entier et avons acquis une bonne réputation grâce à la qualité supérieure de nos produits et à notre service après-vente. Nous invitons chaleureusement nos clients, tant nationaux qu'étrangers, à nous contacter pour négocier des affaires, échanger des informations, et... coopérer avec nous!

Visitez notre usine de RV :

Visitez notre usine de RV avec les éléments suivants

Comment fonctionne le vérin hydraulique d'un chariot élévateur ?

Vérin hydraulique Application :