Mobile Crane Telescopic Cylinder

En tant que fabricant, fournisseur et exportateur de produits mécaniques, nous proposons des vérins hydrauliques et de nombreux autres produits.

N'hésitez pas à nous contacter pour plus de détails.

Courrier :sales@hydraulic-cylinders.net

Fabricant fournisseur exportateur de vérins hydrauliques.

Mobile Crane Telescopic Cylinder

The mobile crane telescopic cylinder is vital in mobile crane systems and is specifically designed to enhance reach and lifting performance. This hydraulic cylinder enables crane operators to extend the boom sections of the crane, allowing for increased vertical and horizontal reach and improved lifting capacity.

The mobile crane telescopic cylinder is a crucial component that enhances mobile cranes’ reach, lifting capacity, and overall performance. With its robust construction, telescopic design, extended reach, and improved lifting capacity, this hydraulic cylinder empowers operators to tackle diverse lifting tasks easily and efficiently. By following the recommended usage methods and maintenance practices, operators can maximize the longevity and performance of the mobile crane telescopic cylinder, contributing to increased productivity, versatility, and safety on construction sites and industrial applications. Invest in this essential hydraulic component to elevate the capabilities of your mobile crane, ensuring successful and efficient lifting operations.

Mobile Crane Telescopic Cylinder Key Characteristics:

- Robust Construction:

- The mobile crane telescopic cylinder is engineered with high-quality materials, ensuring durability and longevity even in demanding operating conditions.

- It is designed to withstand heavy loads, vibrations, and extreme weather conditions, providing reliable performance throughout its lifespan.

- Telescopic Design:

- This hydraulic cylinder features a telescoping mechanism that allows for the extension and retraction of multiple boom sections.

- The telescopic design enables the crane to reach greater heights and distances, making it suitable for a wide range of lifting tasks.

- Enhanced Reach and Flexibility:

- By extending the boom sections, the telescopic cylinder significantly increases the crane’s reach, both vertically and horizontally.

- It enables operators to access elevated work areas, maneuver around obstacles, and reach over obstacles, enhancing the crane’s versatility on the job site.

- Improved Lifting Capacity:

- The telescopic cylinder enhances the crane’s lifting capacity by providing greater stability and reducing the stress on individual boom sections.

- It distributes the load more evenly across the extended boom, allowing for safer and more efficient lifting operations.

Mobile Crane Telescopic Cylinder Parameter:

| Product Name | Mobile Crane Telescopic Cylinder |

| Features: | Realize the linear telescopic movement of the boom |

| Bore diameter: | 75mm~360mm |

| Rod diameter: | 50mm~320mm Stroke≤22000mm |

| Pressure: | Maximum 42MPa |

| Hydraulic Steering Cylinder Applications: | Mobile Crane |

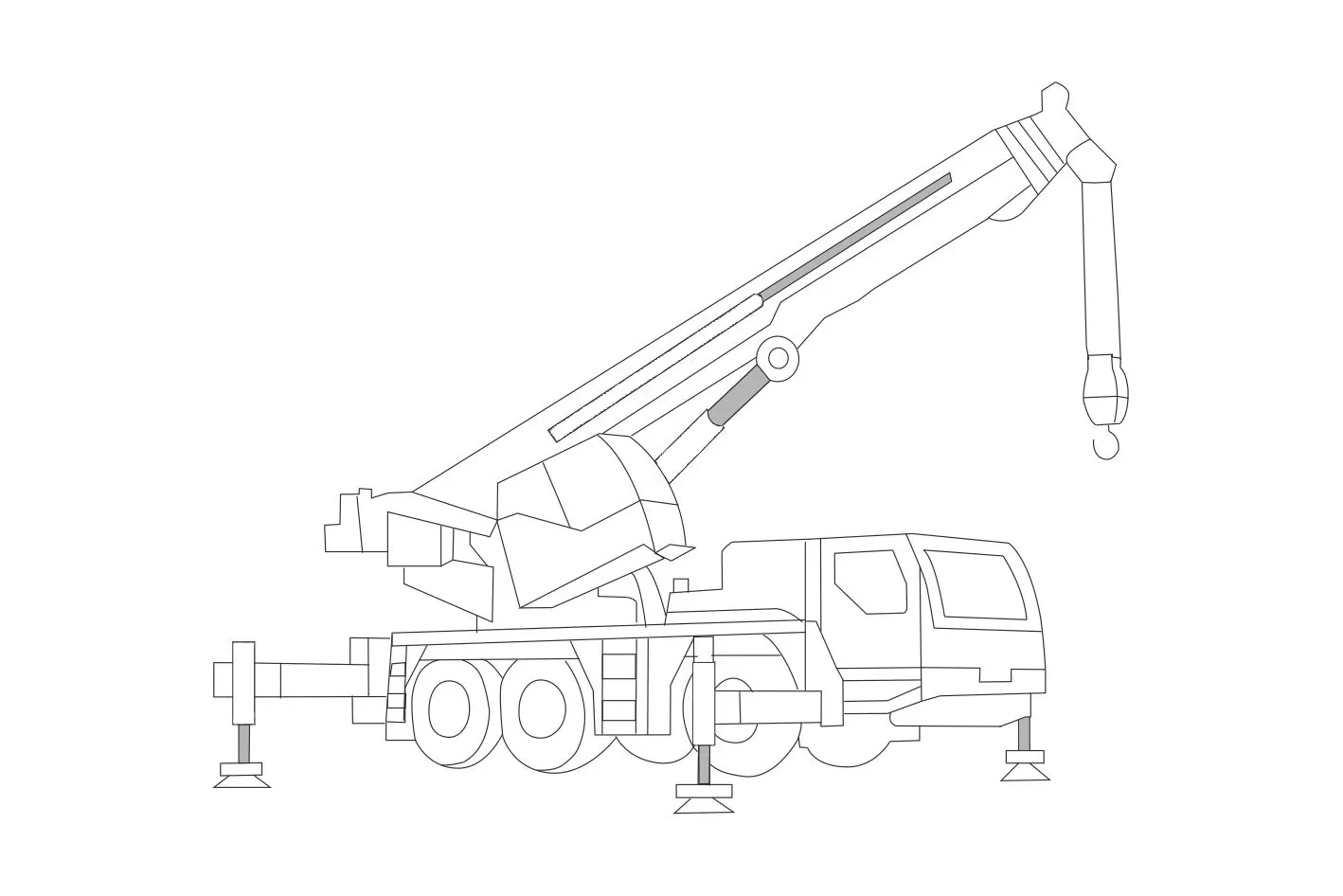

Mobile Crane Identification Diagram:

Usage Method Of Mobile Crane Telescopic Cylinder:

- Safety Precautions:

- Before operating the mobile crane, ensure all safety guidelines and regulations are followed.

- Conduct a thorough inspection of the crane and its components, including the telescopic cylinder, to ensure they are in proper working condition.

- Familiarize with Controls:

- Understand the control mechanisms and operating procedures specific to your mobile crane model.

- Identify the controls responsible for extending and retracting the telescopic boom sections.

- Extending the Boom:

- Activate the appropriate control to extend the telescopic cylinder, allowing the boom sections to develop fully.

- Follow the manufacturer’s guidelines and load charts to determine the safe extension limits based on the load weight and radius.

- Retracting the Boom:

- When the lifting operation is complete, activate the control to retract the telescopic cylinder, bringing the boom sections back to their resting position.

- Ensure that each section retracts smoothly and aligns properly with the adjacent areas.

How To Bleed Air From A Hydraulic System?

Bleeding air from a hydraulic system is necessary to ensure proper operation and prevent issues such as reduced performance, spongy response, or erratic behavior. Here’s a step-by-step guide on how to bleed air from a hydraulic system:

- Identify Bleed Points:

- Determine the locations in the hydraulic system where air can be trapped. Common bleed points include air bleed valves, bleed screws, or fittings with removable caps.

- Consult the system’s manual or manufacturer guidelines for specific information on bleed points.

- Prepare the System:

- Ensure the hydraulic system is turned off and the pressure is fully released.

- If applicable, locate the hydraulic fluid reservoir and check the fluid level. Maintain the liquid level within the recommended range.

- Start at the Lowest Point:

- Begin the bleeding process at the lowest point in the system where air can accumulate.

- Loosen the air bleed valve or remove the fitting cap to expose the bleed screw.

- Open the Bleed Point:

- Use an appropriate tool, such as a wrench or screwdriver, to slowly open the air bleed valve or loosen the bleed screw.

- Be cautious not to remove the valve or screw, which may result in fluid leakage.

- Purge the Air:

- As the bleed point is opened, air bubbles may start to escape along with hydraulic fluid.

- Allow the air to purge from the system until a steady fluid flow without air bubbles is observed.

- Keep a container or absorbent material handy to catch any fluid that may spill during this process.

- Close the Bleed Point:

- Once the air is purged, close the air bleed valve or tighten the bleed screw securely.

- Ensure the valve or screw is adequately sealed to prevent further air entry.

- Move to the Next Bleed Point:

- Proceed to the next highest point in the system where air can accumulate, and repeat steps 4-6.

- Continue bleeding the system at each identified bleed point, working your way up to the highest point.

- Check Fluid Level:

- Monitor the fluid level in the reservoir throughout the bleeding process and top up if necessary.

- Use the recommended hydraulic fluid specified in the system’s manual or by the manufacturer.

- Test and Verify:

- After bleeding all the identified points, operate the hydraulic system to ensure proper functionality.

- Check for any signs of spongy response, abnormal noises, or erratic behavior.

- Repeat the bleeding process if issues persist or consult a qualified technician for further assistance.

Capacité de l'usine :

(1) Assemblage

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Usinage

L'atelier d'usinage est équipé d'un centre de tournage sur rail incliné personnalisé, d'un centre d'usinage, d'une machine à honer à grande vitesse, d'un robot de soudage et d'autres équipements connexes, qui peuvent traiter des tubes cylindriques d'un diamètre intérieur maximal de 400 mm et d'une longueur maximale de 6 mètres.

(3) Soudage

(4) Peinture et revêtement

Avec des lignes de revêtement de peinture à base d'eau automatiques à cylindre de petite et moyenne taille, pour réaliser le chargement et le déchargement automatiques par robot et la pulvérisation automatique, la capacité de conception est de 4 000 pièces par équipe ;

Nous disposons également d'une ligne de production de peinture semi-automatique pour gros cylindres, alimentée par une chaîne de traction, d'une capacité de conception de 60 caisses par équipe.

(5) Essais

Nous disposons d'installations d'inspection et de bancs d'essai de premier ordre pour garantir que les performances de la bouteille sont conformes aux exigences.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding boîtes de vitesses agricoles. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and coopérer avec nous!

Visitez notre usine de RV :

Visitez notre usine de RV avec les éléments suivants

Comment fonctionne le vérin hydraulique d'un chariot élévateur ?

Vérin hydraulique Application :