Replacement Of 5HG620104 Boom Hinge Hydraulic Cylinder

Yhtenä hydraulisylinterien valmistajista, toimittajista ja mekaanisten tuotteiden viejistä tarjoamme hydraulisylintereitä ja monia muita tuotteita.

Ota yhteyttä meihin saadaksesi lisätietoja.

Posti:sales@hydraulic-cylinders.net

Valmistaja toimittaja viejä hydraulisylinterit.

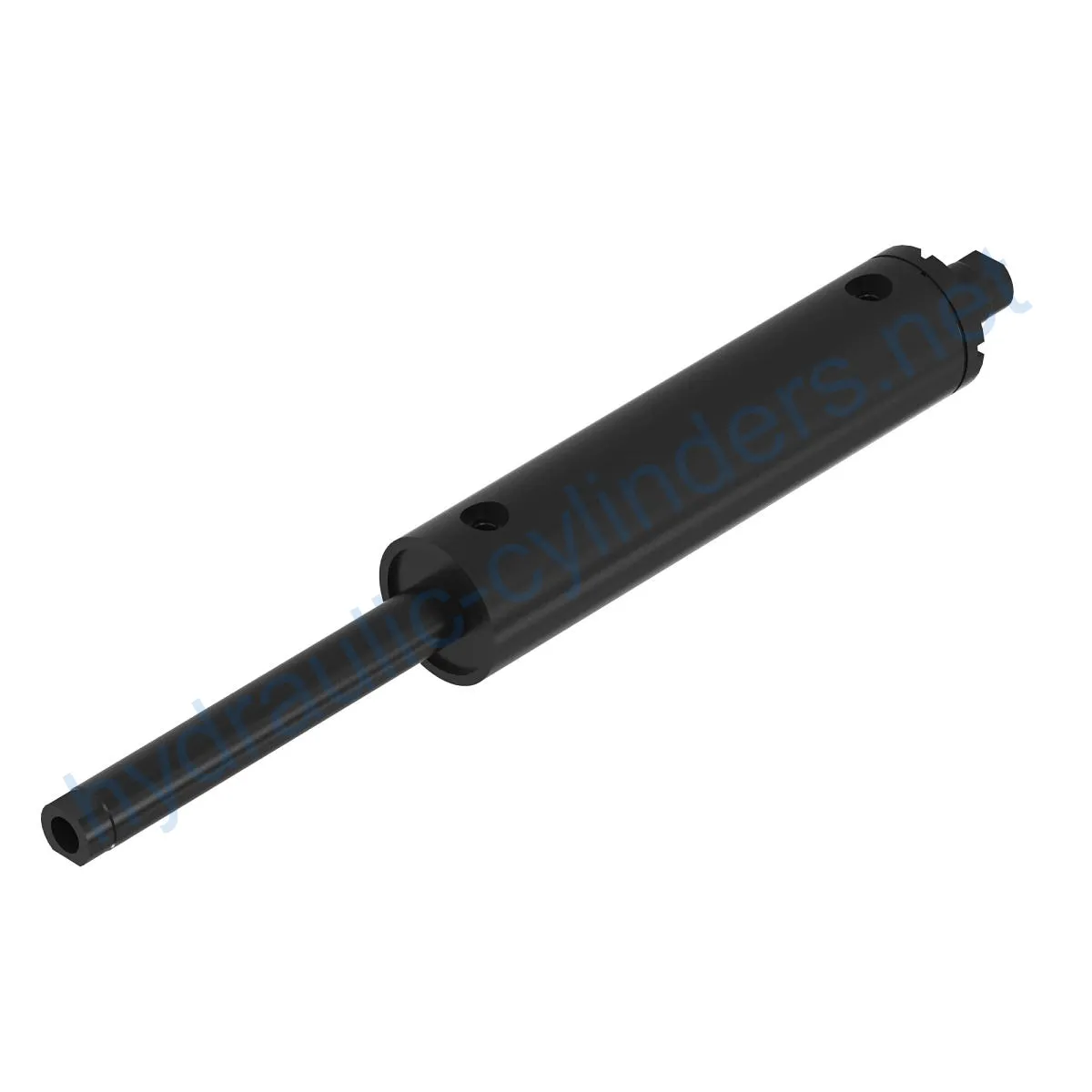

Replacement Of 5HG620104 Boom Hinge Hydraulic Cylinder

The Replacement Of 5HG620104 Boom Hinge Hydraulic Cylinder is a hydraulic cylinder replacement part used for various applications. The hydraulic cylinder weighs 2.22 lb, has a height of 1.7 in, and length of 8.7 in. This hydraulic cylinder is designed to be compatible with different models of equipment.

Product Specifications

Weight

The hydraulic cylinder weighs 2.22 lb.

Height

The hydraulic cylinder has a height of 1.7 in.

Length

The hydraulic cylinder has a length of 8.7 in.

Product Features

The Replacement Of 5HG620104 Boom Hinge Hydraulic Cylinder has various features, including:

1. Improved Equipment Performance

Replacing damaged or worn hydraulic cylinders can restore the equipment’s normal operational capability and ensure performance in various applications.

2. Enhanced Safety

Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failures and ensure the safety of operators and equipment.

3. Overload Protection

New cylinder designs usually consider better overload protection mechanisms, improving safety.

4. Quick Installation

Modern hydraulic cylinders are designed for easy installation and replacement, reducing downtime.

5. Standardized Parts

Many hydraulic cylinders are standardized products, making it easy to obtain replacement parts in the market.

We manufacture hydraulic cylinders and have the capability to produce the Replacement Of 5HG620104 Boom Hinge Hydraulic Cylinder. Our product can perfectly replace these hydraulic cylinders.

Applications

The Replacement Of 5HG620104 Boom Hinge Hydraulic Cylinder is used in various applications, including:

1. Excavators

In excavator arms or buckets, hydraulic cylinders may be damaged due to long-term use or overload and need replacement to restore normal operation.

2. Cranes

The crane’s boom hydraulic cylinders are prone to wear during frequent lifting and lowering and require regular replacement to ensure safety.

3. Tractors

The front-end loader hydraulic cylinders of tractors may leak or experience performance degradation during continuous lifting and tilting operations, requiring replacement.

For each application, the following is a more detailed description:

Excavators

In an excavator, the hydraulic cylinder is used to help operate the arms and bucket. The hydraulic cylinder can become damaged due to long-term use or overload. Replacing the damaged hydraulic cylinder with the Replacement Of 5HG620104 Boom Hinge Hydraulic Cylinder can restore normal operation to the excavator.

Cranes

A crane’s boom hydraulic cylinders are used to lift and lower the load. Frequent lifting and lowering can cause wear and tear on the hydraulic cylinder, requiring regular replacement to ensure safety. The Replacement Of 5HG620104 Boom Hinge Hydraulic Cylinder can help maintain the crane’s safe operation.

Tractors

The front-end loader hydraulic cylinders of tractors are used to lift and tilt the bucket. The hydraulic cylinder may leak or experience performance degradation during continuous lifting and tilting operations, requiring replacement. The Replacement Of 5HG620104 Boom Hinge Hydraulic Cylinder can help restore the tractor’s normal operation.

Maintenance Tasks

The following are common maintenance tasks for hydraulic cylinders:

1. Regular Inspection

Regular inspection of hydraulic cylinders ensures that they are functioning correctly and can detect problems before they cause failure.

2. Proper Lubrication

Proper lubrication of hydraulic cylinders ensures they operate smoothly and extends their lifespan. Hydraulic cylinders require regular oiling to maintain their performance.

3. Seal Replacement and Calibration Check

Replacing seals and checking the calibration of hydraulic cylinders ensures their proper function and prevents leakage. Proper installation, lubrication, and adjustment are critical to the hydraulic cylinder’s performance. Properly aligning the cylinder and using appropriate installation brackets to secure it is important during installation. We recommend regular inspection, repair, and replacement services to improve the hydraulic cylinder’s lifespan.

Safety Considerations and Environmental Factors

When using hydraulic cylinders, safety measures are essential to protect the operator and the equipment. Proper installation, use, and maintenance of hydraulic cylinders can help avoid safety hazards and potential environmental damage.

Troubleshooting and Common Issues

The following are common issues with hydraulic cylinders:

1. Leaking Hydraulic Fluid

When there is a leak in the hydraulic cylinder, it may indicate an issue with the seals or valve. Replacing the seals or valves may solve the problem.

2. Slow Operation

Slow hydraulic cylinder operation can be due to low fluid levels or a damaged piston. Refilling the fluid or replacing the piston may solve the problem.

3. Noisy Operation

Noisy hydraulic cylinder operation can be due to a damaged bearing or bushing. Replacement of the bearing or bushing may solve the problem.

Preventive measures include regular inspection, lubrication, and replacement of seals, pistons, bearings, and bushings. Proper installation, alignment, and calibration are also essential.

Design Considerations and Selection Criteria

When selecting hydraulic cylinders, it is essential to consider the cylinder’s load-bearing capacity, sealing, durability, safety, and repairability. Hydraulic cylinders have to withstand a high load, and their seals should be made of wear-resistant materials such as polyurethane and nitrile rubber. The cylinder surfaces should be precisely machined to increase wear resistance. Regular oiling of the cylinder is essential to maintain its performance.

Regular inspection and preventive maintenance can prevent cylinder failure and extend its lifespan.

Company Overview

We are a hydraulic cylinder manufacturer specializing in hydraulic cylinder replacements. With a complete range of products, we have become one of the leading manufacturers and wholesale distributors of hydraulic cylinders in domestic and international markets. Our company is known for its professionalism, international certification, customized services, advanced production equipment, and excellent after-sales service.

Author: lyl

Tutustu VR-tehtaaseemme:

Tutustu VR-tehtaaseemme seuraavalla kierroksella

Miten haarukkatrukin hydraulisylinteri toimii?

Hydraulisylinteri Sovellus: