Mobile Crane Counterweight Cylinder

Yhtenä hydraulisylinterien valmistajista, toimittajista ja mekaanisten tuotteiden viejistä tarjoamme hydraulisylintereitä ja monia muita tuotteita.

Ota yhteyttä meihin saadaksesi lisätietoja.

Posti:sales@hydraulic-cylinders.net

Valmistaja toimittaja viejä hydraulisylinterit.

Mobile Crane Counterweight Cylinder

The mobile crane counterweight cylinder is a vital component that plays a crucial role in achieving balance and stability during lifting operations. Designed specifically for mobile cranes, this hydraulic cylinder ensures the controlled movement and positioning of the counterweight, optimizing the crane’s lifting capacity and enhancing overall safety.

The mobile crane counterweight cylinder is an indispensable component that enables balance, stability, and enhanced safety in mobile crane lifting operations. With its robust construction, precise hydraulic control, and ability to adjust the counterweight position, this hydraulic cylinder optimizes the crane’s lifting capacity and ensures controlled movement, minimizing the risk of accidents and ensuring safe and efficient lifting. Following proper usage methods and adhering to recommended maintenance practices, operators can maximize the lifespan and reliability of the mobile crane counterweight cylinder, leading to successful and secure lifting operations. Choose this essential hydraulic component for balance, stability, and safety in your mobile crane lifting endeavors.

Mobile Crane Counterweight Cylinder Key Characteristics:

- Robust Construction and Durability:

- The mobile crane counterweight cylinder boasts a robust construction, utilizing high-quality materials to ensure strength and durability.

- It is engineered to withstand heavy loads, shocks, and harsh environmental conditions, guaranteeing reliable performance even in demanding work environments.

- Hydraulic Control and Precision:

- This cylinder operates through a hydraulic control system, allowing for precise movement and adjustment of the counterweight.

- The hydraulic control ensures smooth and controlled operation, enabling operators to achieve the desired balance with utmost precision.

- Optimal Counterweight Positioning:

- The mobile crane counterweight cylinder facilitates the controlled movement and positioning of the counterweight.

- Adjusting the counterweight’s position allows operators to achieve improved stability and enhance the crane’s lifting capacity, enabling safe and efficient lifting operations.

- Enhanced Safety and Stability:

- The counterweight plays a significant role in counterbalancing the lifted load maintaining the crane’s stability throughout the operation.

- The mobile crane counterweight cylinder enables precise control over the counterweight, ensuring balanced and stable lifting, reducing the risk of accidents, and enhancing overall safety.

Mobile Crane Counterweight Cylinder Parameter:

| Product Name | Mobile Crane Counterweight Cylinder |

| Features: | For the installation of counterweights, |

| Bore diameter: | 85mm~320mm |

| Rod diameter: | 55mm~180mm Stroke≤1500mm |

| Pressure: | Maximum 35MPa |

| Telescopic Cylinder Applications: | Mobile Crane |

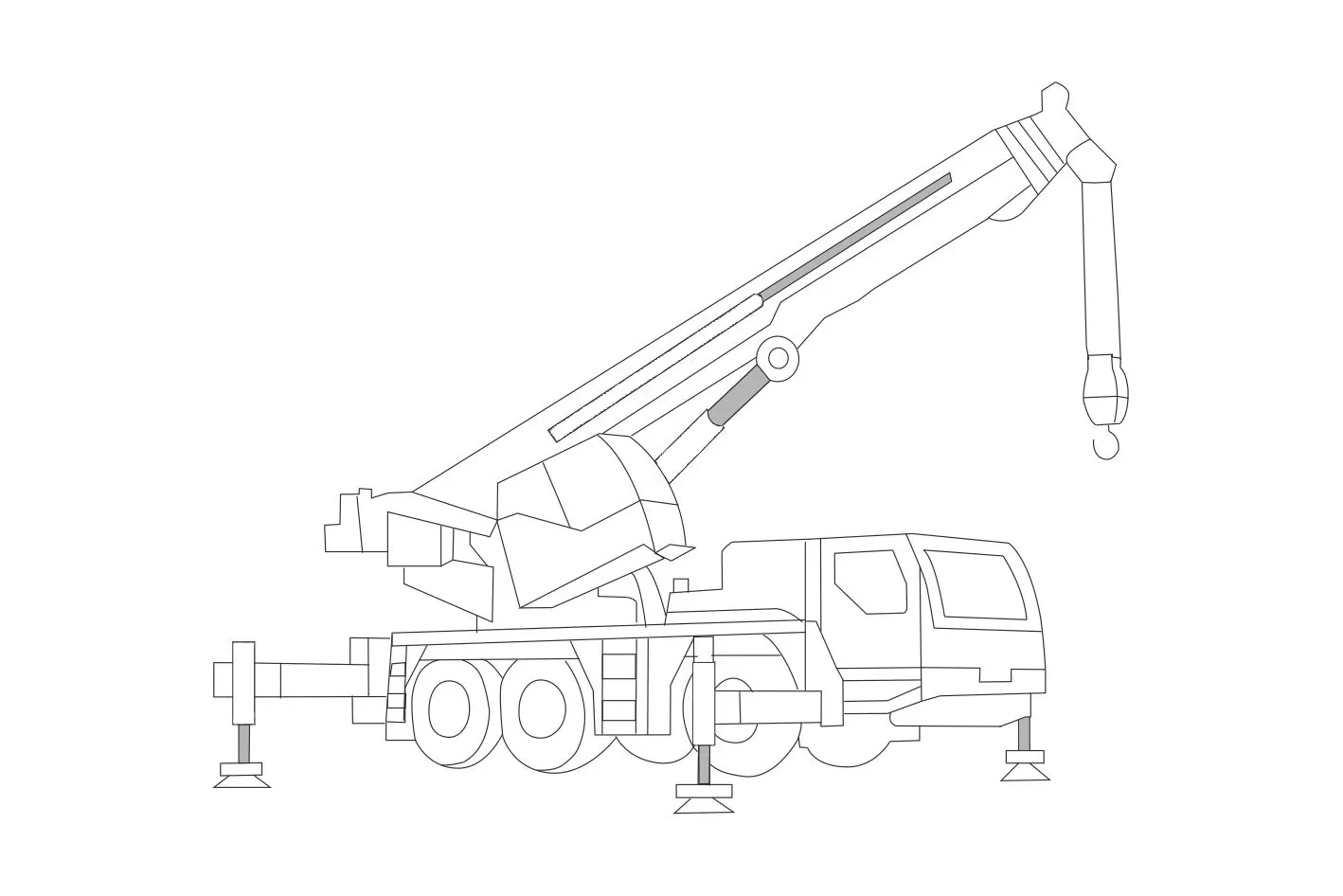

Mobile Crane Identification Diagram:

Usage Method Of Mobile Crane Counterweight Cylinder:

- Familiarize with Controls and Safety Guidelines:

- Before operating the mobile crane counterweight cylinder, operators must familiarize themselves with the crane’s controls and safety guidelines.

- Ensure that all safety procedures and precautions, including proper counterweight positioning, are followed to ensure safe lifting operations.

- Adjusting the Counterweight:

- The hydraulic controls adjust the counterweight’s position per the lifting requirements.

- Gradually move the counterweight to achieve the desired balance and stability.

- Monitor the crane’s performance and adjust the counterweight position during the lifting operation as needed.

- Fine-Tuning the Balance:

- Throughout the lifting operation, operators should continuously monitor the crane’s stability.

- If required, make minor adjustments to the counterweight position to maintain the crane’s balance and ensure safe lifting.

What Are The Main Components Of A Hydraulic System?

A hydraulic system consists of several key components that work together to transmit power and control the movement of fluids. The main components of a hydraulic system are:

- Hydraulic Fluid:

- Hydraulic fluid is the medium through which power is transmitted in a hydraulic system.

- It is typically a specially formulated oil with excellent lubricating and pressure transmission properties.

- The hydraulic fluid transfers force from one component to another and plays a vital role in the overall system performance.

- Hydraulic Pump:

- The hydraulic pump generates flow and provides the necessary pressure to move the hydraulic fluid.

- It converts mechanical energy into hydraulic energy, typically from an electric motor or an engine.

- The pump draws in hydraulic fluid from the reservoir and delivers it to the rest of the hydraulic system at high pressure.

- Reservoir:

- The reservoir, also known as the hydraulic tank, stores the hydraulic fluid.

- It provides a fluid supply for the pump and helps dissipate heat generated during system operation.

- The reservoir usually contains a filter to remove contaminants and a halt to maintain the proper fluid level and prevent the entry of contaminants or air.

- Hydraulic Actuators:

- Hydraulic actuators are devices that convert hydraulic energy into mechanical force or motion.

- The two most common hydraulic actuators are hydraulic cylinders and hydraulic motors.

- Hydraulic cylinders utilize the pressure of the hydraulic fluid to generate linear motion, while hydraulic motors convert fluid pressure into rotary motion.

- Control Valves:

- Control valves regulate the flow and pressure of hydraulic fluid throughout the system.

- They direct the fluid to different actuators and control the speed and direction of movement.

- Control valves can be manually operated or automated using solenoids or other control mechanisms.

- Hydraulic Lines and Hoses:

- Hydraulic lines and hoses transport the hydraulic fluid between various components of the system.

- They are designed to withstand high-pressure conditions and are constructed from materials that are compatible with hydraulic fluids.

- Proper installation and maintenance of hydraulic lines and hoses are crucial to prevent leaks and ensure optimal system performance.

- Accumulators:

- Accumulators store pressurized hydraulic fluid for future use.

- They help maintain system pressure, absorb shocks, and provide additional power during peak demand.

- Accumulators are often used in applications where rapid or intermittent hydraulic energy is required.

- Filters:

- Filters remove contaminants and impurities from the hydraulic fluid.

- They prevent particles, debris, and other contaminants from causing damage to system components and ensure fluid cleanliness.

- Filters are typically installed in the hydraulic lines or within the reservoir.

Tehtaan kapasiteetti ja kapasiteetti:

(1) Kokoonpano

Meillä on ensiluokkainen riippumaton tutkimus- ja kehitystyön kokoonpanoalusta. Hydraulisylinterien tuotantopajassa on neljä puoliautomaattista nostosylinterin kokoonpanolinjaa ja yksi automaattinen kallistussylinterin kokoonpanolinja, joiden suunniteltu vuotuinen tuotantokapasiteetti on 1 miljoona kappaletta. Erikoissylinterin työpaja on varustettu erilaisilla eritelmillä puoliautomaattisen puhdistusasennuksen kokoonpanojärjestelmällä, jonka suunniteltu vuotuinen tuotantokapasiteetti on 200 000, ja se on varustettu kuuluisilla CNC-työstölaitteilla, työstökeskuksella, korkean tarkkuuden sylinterin käsittelyyn tarkoitetuilla erityislaitteilla, robottihitsauskoneella, automaattisella puhdistuslaitteella, automaattisella sylinterin kokoonpanokoneella ja automaattisella maalaustuotantolinjalla. Olemassa olevat kriittiset laitteet yli 300 sarjaa (sarjaa). Laiteresurssien optimaalinen kohdentaminen ja tehokas käyttö varmistavat tuotteiden tarkkuusvaatimukset ja täyttävät tuotteiden laatuvaatimukset.

(2) Koneistus

Työstöpaja on varustettu räätälöidyllä kaltevalla kiskosorvauskeskuksella, työstökeskuksella, suurnopeus-hiontakoneella, hitsausrobotilla ja muilla vastaavilla laitteilla, joilla voidaan käsitellä sylinteriputkia, joiden sisähalkaisija on enintään 400 mm ja enimmäispituus on 6 metriä.

(3) Hitsaus

(4) Maalaus ja pinnoitus

Pienillä ja keskisuurilla sylinterin automaattisilla vesipohjaisilla maalipinnoituslinjoilla automaattisen robotin lastaus- ja purku- ja automaattisen ruiskutuksen saavuttamiseksi, suunnittelukapasiteetti on 4000 kappaletta vuorossa;

Meillä on myös puoliautomaattinen maalauslinja suurille sylintereille, joka toimii voimaketjulla ja jonka suunnittelukapasiteetti on 60 laatikkoa työvuorossa.

(5) Testaus

Meillä on ensiluokkaiset tarkastustilat ja testialustat, joilla varmistetaan, että sylinterin suorituskyky täyttää vaatimukset.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding maatalousvaihteistot. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and tehdä yhteistyötä kanssamme!

Tutustu VR-tehtaaseemme:

Tutustu VR-tehtaaseemme seuraavalla kierroksella

Miten haarukkatrukin hydraulisylinteri toimii?

Hydraulisylinteri Sovellus: