Head suorakulmainen laippa tyyppi Metallurginen hydraulinen sylinteri

Yhtenä hydraulisylinterien valmistajista, toimittajista ja mekaanisten tuotteiden viejistä tarjoamme hydraulisylintereitä ja monia muita tuotteita.

Ota yhteyttä meihin saadaksesi lisätietoja.

Posti:sales@hydraulic-cylinders.net

Valmistaja toimittaja viejä hydraulisylinterit.

Head suorakulmainen laippa tyyppi Metallurginen hydraulinen sylinteri

The rectangular flange type metallurgical hydraulic cylinder is a state-of-the-art element specially designed for metallurgical applications. With its innovative design, superior performance, and rugged construction, this hydraulic cylinder ensures precise control, reliable operation, and exceptional durability in demanding industrial environments. Whether used in steel mills, foundries, or other metallurgical processes, head rectangular flange-type cylinders provide efficiency and productivity.

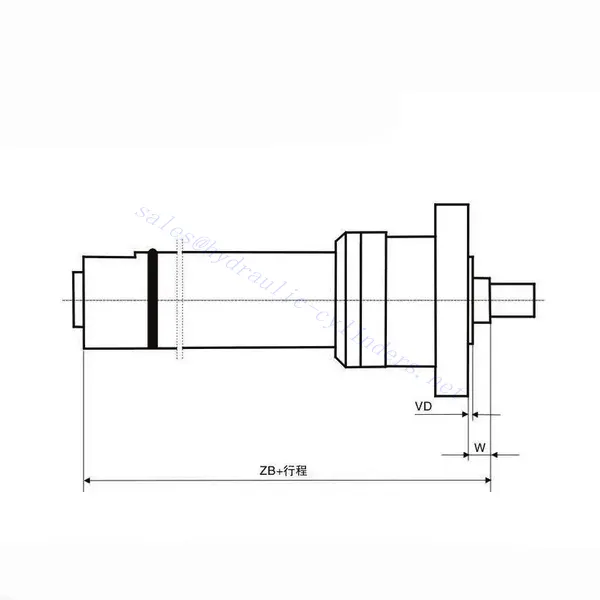

The hydraulic cylinder of Y-HG1 series metallurgical equipment is a double-acting piston cylinder; the cylinder diameter is generally within the range of 40~320mm, and the working pressure is <=16MPA. The hydraulic oil system can transport the active medium, such as emulsion, and install different models, such as flanges, earrings, pins, and release devices (base).

High precision CNC honing machine, automatic welding machine, vertical, horizontal machining center, gantry machining center, CNC lathe, and other processing equipment, product quality is stable and guaranteed.

Head Rectangular Flange Type Metallurgical Hydraulic Cylinder Parameter:

Head suorakulmainen laippa tyyppi Metallurginen hydraulinen sylinteri Käyttömenetelmä:

- Asennus ja asennus:

- Identify the appropriate mounting location for the metallurgical hydraulic cylinder based on the specific requirements of the metallurgical equipment.

- Ensure that the mounting surface is clean, flat, and capable of supporting the weight and load of the cylinder.

- Connection to Hydraulic System:

- Connect the metallurgical hydraulic cylinder to the hydraulic system using compatible hydraulic hoses or pipes.

- Ensure proper alignment and secure connections to prevent leaks.

- System Integration and Calibration:

- Integrate the metallurgical hydraulic cylinder into the metallurgical equipment or system following the manufacturer’s guidelines.

- Calibrate the system to achieve optimal performance and desired operation parameters.

- Operating the Cylinder:

- Activate the hydraulic system to apply pressure and initiate the movement of the hydraulic cylinder.

- Utilize the hydraulic control system to control the cylinder’s extension, retraction, and precise positioning for efficient metallurgical operations.

Characteristics Of Head Rectangular Flange Type Metallurgical Hydraulic Cylinder:

- Head Rectangular Flange Design: The unique rectangular flange design provides enhanced stability, precise alignment, and improved load distribution during operation, ensuring optimal performance in metallurgical processes.

- Metallurgical Application Focus: This metallurgical hydraulic cylinder is precisely engineered to meet the demanding requirements of metallurgical applications, offering reliability and durability in extreme conditions.

- Superior Performance: The cylinder delivers exceptional performance, enabling accurate positioning, smooth operation, and efficient productivity in metallurgical processes.

- Vankka rakenne: Constructed from high-quality materials and designed to withstand heavy loads and harsh operating conditions, this metallurgical hydraulic cylinder ensures long-term durability and reliable performance.

- Safety Features: The design incorporates overload protection and emergency stop mechanisms, prioritizing operator safety during metallurgical processes.

How To Find Seal Kit For Hydraulic Cylinder?

Finding the correct seal kit for a hydraulic cylinder is crucial to ensure proper fit, functionality, and performance. Here are some steps to help you find the appropriate seal kit:

- Identify the Cylinder Manufacturer and Model:

- Determine the manufacturer of the hydraulic cylinder. This information is often stamped or engraved on the cylinder body.

- If possible, note down the model number or any other identifying markings on the cylinder.

- Gather Cylinder Specifications:

- Measure the dimensions of the cylinder, including the bore diameter, rod diameter, and stroke length.

- Note any specific features or configurations unique to the cylinder, such as flanges, ports, or mounting styles.

- Research the Manufacturer’s Resources:

- Visit the manufacturer’s website or contact customer support to inquire about available seal kits for your specific cylinder model.

- Provide the manufacturer with the cylinder specifications and any identifying information you have gathered.

- Explore Online Hydraulic Seal Suppliers:

- Search for reputable online hydraulic seal suppliers or distributors.

- Utilize search filters or navigation menus on their websites to narrow down the selection based on cylinder specifications or manufacturer.

- Utilize Seal Kit Cross-Reference Tools:

- Some seal kit suppliers offer cross-reference tools or databases that help match cylinder models with compatible seal kits.

- Enter the cylinder manufacturer, model, or other specifications into the cross-reference tool to find suitable seal kits.

- Consult Hydraulic System Maintenance Manuals:

- Check if the equipment or machinery that uses the hydraulic cylinder has a maintenance manual.

- The manual may include information on recommended seal kits or part numbers.

- Seek Assistance from Hydraulic Experts:

- Reach out to hydraulic system specialists, maintenance professionals, or engineers with expertise in hydraulic systems.

- They can guide and recommend finding the correct seal kit for your hydraulic cylinder.

- Consider Custom Seal Kits:

- If you cannot find a seal kit specifically designed for your cylinder model, consider contacting a manufacturer or supplier that offers custom seal kits.

- Please provide them with accurate measurements and cylinder specifications to have a seal kit tailored to your requirements.

- Purchase and Install the Seal Kit:

- Once you have identified the appropriate seal kit, place an order with the supplier or manufacturer.

- Follow the installation instructions with the seal kit carefully to ensure proper installation and optimal performance.

Tehtaan kapasiteetti ja kapasiteetti:

(1) Kokoonpano

Meillä on ensiluokkainen riippumaton tutkimus- ja kehitystyön kokoonpanoalusta. Hydraulisylinterien tuotantopajassa on neljä puoliautomaattista nostosylinterin kokoonpanolinjaa ja yksi automaattinen kallistussylinterin kokoonpanolinja, joiden suunniteltu vuotuinen tuotantokapasiteetti on 1 miljoona kappaletta. Erikoissylinterin työpaja on varustettu erilaisilla eritelmillä puoliautomaattisen puhdistusasennuksen kokoonpanojärjestelmällä, jonka suunniteltu vuotuinen tuotantokapasiteetti on 200 000, ja se on varustettu kuuluisilla CNC-työstölaitteilla, työstökeskuksella, korkean tarkkuuden sylinterin käsittelyyn tarkoitetuilla erityislaitteilla, robottihitsauskoneella, automaattisella puhdistuslaitteella, automaattisella sylinterin kokoonpanokoneella ja automaattisella maalaustuotantolinjalla. Olemassa olevat kriittiset laitteet yli 300 sarjaa (sarjaa). Laiteresurssien optimaalinen kohdentaminen ja tehokas käyttö varmistavat tuotteiden tarkkuusvaatimukset ja täyttävät tuotteiden laatuvaatimukset.

(2) Koneistus

Työstöpaja on varustettu räätälöidyllä kaltevalla kiskosorvauskeskuksella, työstökeskuksella, suurnopeus-hiontakoneella, hitsausrobotilla ja muilla vastaavilla laitteilla, joilla voidaan käsitellä sylinteriputkia, joiden sisähalkaisija on enintään 400 mm ja enimmäispituus on 6 metriä.

(3) Hitsaus

(4) Maalaus ja pinnoitus

Pienillä ja keskisuurilla sylinterin automaattisilla vesipohjaisilla maalipinnoituslinjoilla automaattisen robotin lastaus- ja purku- ja automaattisen ruiskutuksen saavuttamiseksi, suunnittelukapasiteetti on 4000 kappaletta vuorossa;

Meillä on myös puoliautomaattinen maalauslinja suurille sylintereille, joka toimii voimaketjulla ja jonka suunnittelukapasiteetti on 60 laatikkoa työvuorossa.

(5) Testaus

Meillä on ensiluokkaiset tarkastustilat ja testialustat, joilla varmistetaan, että sylinterin suorituskyky täyttää vaatimukset.

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding maatalousvaihteistot. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and tehdä yhteistyötä kanssamme!

Tutustu VR-tehtaaseemme:

Tutustu VR-tehtaaseemme seuraavalla kierroksella

Miten haarukkatrukin hydraulisylinteri toimii?

Hydraulisylinteri Sovellus: