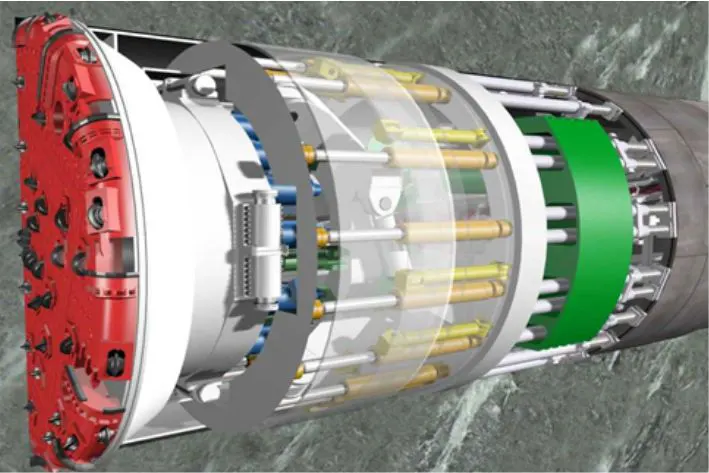

Double Shield TBM Auxiliary Thrust Cylinder

Yhtenä hydraulisylinterien valmistajista, toimittajista ja mekaanisten tuotteiden viejistä tarjoamme hydraulisylintereitä ja monia muita tuotteita.

Ota yhteyttä meihin saadaksesi lisätietoja.

Posti:sales@hydraulic-cylinders.net

Valmistaja toimittaja viejä hydraulisylinterit.

Double Shield TBM Auxiliary Thrust Cylinder

The double shield TBM auxiliary thrust cylinder is a cutting-edge hydraulic component that is vital in optimizing tunnel boring machines’ performance. This specialized cylinder is designed to provide auxiliary thrust force, supporting the main thrust cylinder and enhancing the efficiency of the tunneling process. This comprehensive article will delve into the key characteristics, usage methods, and maintenance guidelines for the double shield tbm auxiliary thrust cylinder.

The double shield TBM auxiliary thrust cylinder is a crucial component that empowers tunnel boring machines to achieve unparalleled efficiency and productivity. With its enhanced thrust support, robust construction, compact design, and precise control mechanisms, this cylinder ensures tunneling operations’ smooth and efficient advancement. By following the recommended usage methods and adhering to regular maintenance practices, the double shield tbm auxiliary thrust cylinder will continue to deliver exceptional performance, contributing to the success of tunneling projects. Embrace the power and reliability of the double shield tbm auxiliary thrust cylinder, revolutionizing tunnel boring with unmatched efficiency and effectiveness.

Double Shield TBM Auxiliary Thrust Cylinder Key Characteristics:

- Enhanced Thrust Support: The double shield auxiliary thrust cylinder is engineered to deliver exceptional auxiliary thrust support to the main thrust cylinder. By providing additional force, it ensures stable and efficient advancement of the tunnel boring machine, even in challenging ground conditions.

- Robust Construction: This cylinder features a robust and durable construction, built to withstand the demanding environments encountered during tunneling operations. Its high-quality materials and meticulous craftsmanship ensure longevity and reliability, even in the harshest conditions.

- Compact Design: The double shield TBM auxiliary thrust cylinder boasts a compact design, allowing for easy integration into the tunnel boring machine. Its space-efficient construction ensures minimal interference with other components, maximizing the overall efficiency of the tunneling process.

- Precise Control Mechanisms: Equipped with advanced control mechanisms, this cylinder offers precise and responsive operation. Operators can adjust the auxiliary thrust force according to specific ground conditions, ensuring optimal performance and minimizing the risk of disruptions.

Double Shield TBM Auxiliary Thrust Cylinder Parameter:

| Product Name | Double Shield Tunnel Boring Machine Auxiliary Thrust Cylinder |

| Features: | Relying on the reaction force of the auxiliary push cylinder to push the tube piece to make the TBM move forward |

| Bore diameter: | 220mm~320mm |

| Rod diameter: | 180mm~240mm Stroke: 2100mm~2600mm |

| Pressure: | up to 35MPa Special requirements up to 45MPa |

| Applications: | Double Shield Tunnel Boring Machine |

Double Shield TBM Cylinder Application:

Usage Method Of Double Shield TBM Auxiliary Thrust Cylinder:

- Cylinder Integration: Install the double shield tbm auxiliary thrust cylinder in the designated location within the tunnel boring machine, following the manufacturer’s guidelines and specifications. Ensure proper alignment and secure attachment to the tbm’s structure using suitable mounting brackets or accessories.

- Hydraulijärjestelmän integrointi: Connect the cylinder to the TBM’s hydraulic system using compatible hoses and fittings. Verify that all connections are secure, leak-free, and properly tightened to ensure optimal hydraulic performance.

- Ohjaus ja toiminta: Familiarize yourself with the TBM’s control system and the specific controls associated with the double shield tbm auxiliary thrust cylinder. Utilize these controls to activate, regulate, and monitor the auxiliary thrust force, adjusting it to match the requirements of the tunneling process and ground conditions.

- Monitoring and Adjustment: Continuously monitor the performance of the double shield tbm auxiliary thrust cylinder and the overall behavior of the tunnel boring machine. Make necessary adjustments to the auxiliary thrust force, taking into account ground conditions, geological variations, and other factors that may impact the tunneling process.

How To Change A Seal On A Hydraulic Cylinder?

Before starting, ensure you have the necessary tools, replacement seals, and a clean working area. Additionally, follow safety precautions to avoid accidents, such as relieving system pressure.

- Prepare the Cylinder:

- Disconnect the hydraulic cylinder from the system and ensure it is depressurized.

- Clean the exterior of the cylinder to prevent dirt or debris from entering during disassembly.

- Place the cylinder on a stable work surface and secure it using clamps or a vise.

- Remove the Retaining Components:

- Identify the retaining components that secure the cylinder head or cap, such as bolts or snap rings.

- Use the appropriate tools (wrenches, sockets, pliers) to loosen and remove these retaining components.

- Set aside the components in a safe place for reassembly.

- Separate the Cylinder Components:

- Gently tap the cylinder head or cap using a soft mallet to break any seal or adhesive bond.

- Slowly and carefully remove the cylinder head or cap, exposing the piston and seal.

- Pay attention to any shims, spacers, or other components present and remove them for later reassembly.

- Remove the Old Seal:

- Inspect the old seal for any damage or wear and identify the type of seal used.

- Depending on the seal type, you may need to use seal removal tools (picks, hooks) or carefully pry it out using a flat-blade screwdriver.

- Take note of the seal orientation for proper installation of the new seal.

- Clean and Inspect:

- Thoroughly clean the cylinder bore, piston, and surrounding components using a lint-free cloth or solvent appropriate for your hydraulic system.

- Inspect all components for any signs of damage, wear, or scoring. Replace any worn or damaged parts as necessary.

- Install the New Seal:

- Lubricate the new seal with hydraulic fluid or a compatible seal lubricant.

- Carefully position the new seal in the seal groove or on the piston, ensuring it is properly oriented as noted during seal removal.

- Use a seal installation tool or a soft mallet to gently press the seal into place, ensuring it is seated correctly and evenly.

- Reassemble the Cylinder:

- Reinstall shims, spacers, or other components removed during disassembly.

- Carefully align the cylinder head or cap with the cylinder body and guide the piston through it.

- Apply a suitable thread sealant or thread-locking compound to the retaining components and reattach them securely.

- Follow the manufacturer’s torque specifications for tightening the retaining components to ensure proper sealing and alignment.

- Test and Verify:

- Reconnect the hydraulic cylinder to the system and ensure all connections are secure.

- Gradually restore system pressure, checking for any leaks or abnormal behavior.

- Fully cycle the hydraulic cylinder to confirm proper operation and seal integrity.

Tehtaan kapasiteetti ja kapasiteetti:

(1) Kokoonpano

Meillä on ensiluokkainen riippumaton tutkimus- ja kehitystyön kokoonpanoalusta. Hydraulisylinterien tuotantopajassa on neljä puoliautomaattista nostosylinterin kokoonpanolinjaa ja yksi automaattinen kallistussylinterin kokoonpanolinja, joiden suunniteltu vuotuinen tuotantokapasiteetti on 1 miljoona kappaletta. Erikoissylinterin työpaja on varustettu erilaisilla eritelmillä puoliautomaattisen puhdistusasennuksen kokoonpanojärjestelmällä, jonka suunniteltu vuotuinen tuotantokapasiteetti on 200 000, ja se on varustettu kuuluisilla CNC-työstölaitteilla, työstökeskuksella, korkean tarkkuuden sylinterin käsittelyyn tarkoitetuilla erityislaitteilla, robottihitsauskoneella, automaattisella puhdistuslaitteella, automaattisella sylinterin kokoonpanokoneella ja automaattisella maalaustuotantolinjalla. Olemassa olevat kriittiset laitteet yli 300 sarjaa (sarjaa). Laiteresurssien optimaalinen kohdentaminen ja tehokas käyttö varmistavat tuotteiden tarkkuusvaatimukset ja täyttävät tuotteiden laatuvaatimukset.

(2) Koneistus

Työstöpaja on varustettu räätälöidyllä kaltevalla kiskosorvauskeskuksella, työstökeskuksella, suurnopeus-hiontakoneella, hitsausrobotilla ja muilla vastaavilla laitteilla, joilla voidaan käsitellä sylinteriputkia, joiden sisähalkaisija on enintään 400 mm ja enimmäispituus on 6 metriä.

(3) Hitsaus

(4) Maalaus ja pinnoitus

Pienillä ja keskisuurilla sylinterin automaattisilla vesipohjaisilla maalipinnoituslinjoilla automaattisen robotin lastaus- ja purku- ja automaattisen ruiskutuksen saavuttamiseksi, suunnittelukapasiteetti on 4000 kappaletta vuorossa;

Meillä on myös puoliautomaattinen maalauslinja suurille sylintereille, joka toimii voimaketjulla ja jonka suunnittelukapasiteetti on 60 laatikkoa työvuorossa.

(5) Testaus

Meillä on ensiluokkaiset tarkastustilat ja testialustat, joilla varmistetaan, että sylinterin suorituskyky täyttää vaatimukset.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding maatalousvaihteistot. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and tehdä yhteistyötä kanssamme!

Tutustu VR-tehtaaseemme:

Tutustu VR-tehtaaseemme seuraavalla kierroksella

Miten haarukkatrukin hydraulisylinteri toimii?

Hydraulisylinteri Sovellus: