50-100 Double Acting Single Axis MDC Series Compact Mold Cylinder

Yhtenä hydraulisylinterien valmistajista, toimittajista ja mekaanisten tuotteiden viejistä tarjoamme hydraulisylintereitä ja monia muita tuotteita.

Ota yhteyttä meihin saadaksesi lisätietoja.

Posti:sales@hydraulic-cylinders.net

Valmistaja toimittaja viejä hydraulisylinterit.

50-100 Double Acting Single Axis MDC Series Compact Mold Cylinder

The double acting single axis MDC Series compact mold cylinder is an advanced hydraulic cylinder designed specifically for die applications. With its innovative features, reliable performance and compact design, this cylinder offers superior functionality and efficiency in a variety of industrial environments. Whether used in injection molding machines, die casting equipment, or other die-related applications, the double-acting single-axis MDC series compact mold cylinders provide precise control and optimal productivity.

· MDC is a compact hydraulic cylinder (cx) with an electrical box and ram rod to control the neutron position of the mold accurately.

· Hydraulic cylinder suitable for plastic mold use.

Compact Mold Cylinder Model Description:

Compact Mold Cylinder Characteristic Data:

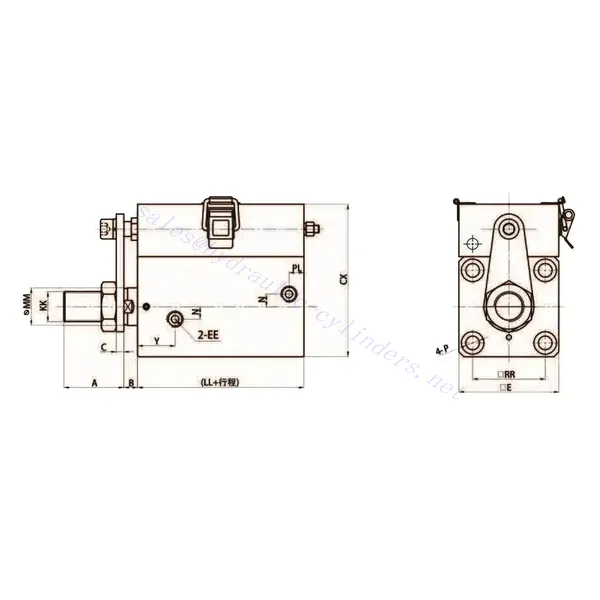

Compact Mold Cylinder Structure Chart:

Piston Rod Connection Size Diagram:

Electrical Box Buckle Position, Oil Port Position, And Distribution Outlet Position:

50-100 Double Acting Single Axis MDC Series Compact Mold Cylinder Parameter:

50-100 Double Acting Single Axis MDC Series Compact Mold Cylinder Key Characteristics and Benefits:

- Double Acting Design:

- The double-acting single-axis MDC series compact cylinders operate in both directions, allowing two-way movement.

- This design can effectively and accurately control the mold’s opening and closing action and improve the operation’s flexibility.

- Single Axis Configuration:

- This cylinder is designed for uniaxial motion, providing straight-line motion in a single direction.

- The single-axis configuration simplifies installation and operation, making it suitable for various die applications.

- Compact and Space-Saving:

- The MDC Series compact mold cylinders’ compact design optimizes the mold system’s space utilization with limited clearance.

- Its space-saving structure can be easily integrated into tight Spaces, ensuring efficient use of available workspace.

- High Precision and Stability:

- The cylinder provides precise and stable movement, ensuring accurate control of mold action during manufacturing.

- It provides consistent and repeatable results that ultimately contribute to high-quality production and reduced waste.

How Hard Is It To Rebuild A Hydraulic Cylinder?

Rebuilding a hydraulic cylinder can be a complex task that requires mechanical knowledge, experience, and the right tools. The difficulty level involved in the process can vary depending on the specific design and condition of the cylinder. Here are some factors to consider:

- Expertise and Experience:

Rebuilding a hydraulic cylinder requires a good understanding of its components, functionality, and assembly. The process may be more manageable if you have experience working with hydraulic systems or have previously rebuilt hydraulic cylinders. However, if you’re new to hydraulic systems, seeking professional assistance or guidance is recommended. - Cylinder Design:

The complexity of rebuilding a hydraulic cylinder can depend on its design. Some cylinders have more straightforward construction with fewer internal components, making them relatively easier to rebuild. However, more advanced techniques, such as those with multiple stages or integrated features, can be more intricate and challenging to disassemble, reseal, and reassemble correctly. - Condition of the Cylinder:

The overall condition of the hydraulic cylinder also affects the rebuilding process. If the cylinder has severe damage, extensive wear, or corrosion, it may require additional repairs or part replacements, which can add complexity to the rebuild. Assessing the cylinder’s condition beforehand will help determine the level of work needed. - Tools and Equipment:

Rebuilding a hydraulic cylinder often requires specialized tools and equipment. These include hydraulic presses, seal installation tools, snap ring pliers and torque wrenches. Having the necessary tools and knowing how to use them properly is crucial for a successful rebuild. - Seal Replacement and Assembly:

One of the critical steps in rebuilding a hydraulic cylinder is replacing the seals. Ensuring the correct selection and installation of seals is critical for proper functioning and preventing leaks. It requires precision and attention to detail. Additionally, reassembling the cylinder components in the correct order and alignment is crucial for its optimal performance. - Testing and Verification:

After rebuilding the hydraulic cylinder, it’s essential to perform thorough testing to ensure it operates as intended. This can involve pressure testing, checking for leaks, and verifying the cylinder’s range of motion and performance. Proper testing helps identify issues and ensures the cylinder is safe and reliable.

Tehtaan kapasiteetti ja kapasiteetti:

(1) Kokoonpano

Meillä on ensiluokkainen riippumaton tutkimus- ja kehitystyön kokoonpanoalusta. Hydraulisylinterien tuotantopajassa on neljä puoliautomaattista nostosylinterin kokoonpanolinjaa ja yksi automaattinen kallistussylinterin kokoonpanolinja, joiden suunniteltu vuotuinen tuotantokapasiteetti on 1 miljoona kappaletta. Erikoissylinterin työpaja on varustettu erilaisilla eritelmillä puoliautomaattisen puhdistusasennuksen kokoonpanojärjestelmällä, jonka suunniteltu vuotuinen tuotantokapasiteetti on 200 000, ja se on varustettu kuuluisilla CNC-työstölaitteilla, työstökeskuksella, korkean tarkkuuden sylinterin käsittelyyn tarkoitetuilla erityislaitteilla, robottihitsauskoneella, automaattisella puhdistuslaitteella, automaattisella sylinterin kokoonpanokoneella ja automaattisella maalaustuotantolinjalla. Olemassa olevat kriittiset laitteet yli 300 sarjaa (sarjaa). Laiteresurssien optimaalinen kohdentaminen ja tehokas käyttö varmistavat tuotteiden tarkkuusvaatimukset ja täyttävät tuotteiden laatuvaatimukset.

(2) Koneistus

Työstöpaja on varustettu räätälöidyllä kaltevalla kiskosorvauskeskuksella, työstökeskuksella, suurnopeus-hiontakoneella, hitsausrobotilla ja muilla vastaavilla laitteilla, joilla voidaan käsitellä sylinteriputkia, joiden sisähalkaisija on enintään 400 mm ja enimmäispituus on 6 metriä.

(3) Hitsaus

(4) Maalaus ja pinnoitus

Pienillä ja keskisuurilla sylinterin automaattisilla vesipohjaisilla maalipinnoituslinjoilla automaattisen robotin lastaus- ja purku- ja automaattisen ruiskutuksen saavuttamiseksi, suunnittelukapasiteetti on 4000 kappaletta vuorossa;

Meillä on myös puoliautomaattinen maalauslinja suurille sylintereille, joka toimii voimaketjulla ja jonka suunnittelukapasiteetti on 60 laatikkoa työvuorossa.

(5) Testaus

Meillä on ensiluokkaiset tarkastustilat ja testialustat, joilla varmistetaan, että sylinterin suorituskyky täyttää vaatimukset.

We are one of the best compact hydraulic cylinder manufacturers. We can offer comprehensive compact hydraulic cylinder stock. We also provide corresponding maatalousvaihteistot. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and tehdä yhteistyötä kanssamme!

Tutustu VR-tehtaaseemme:

Tutustu VR-tehtaaseemme seuraavalla kierroksella

Miten haarukkatrukin hydraulisylinteri toimii?

Hydraulisylinteri Sovellus: