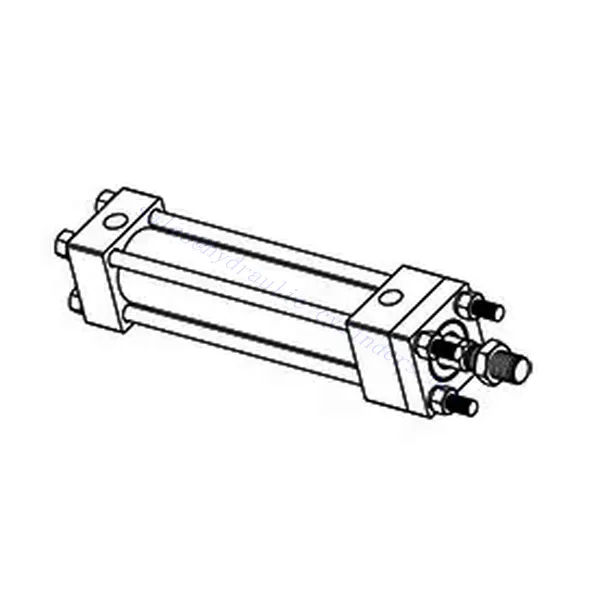

Standardne raske varda hüdrosilinder

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

Standardne raske varda hüdrosilinder

The standard heavy rod hydraulic cylinder is a robust and reliable hydraulic element that provides superior power and durability in various industrial applications. Precisely designed to withstand harsh conditions, this hydraulic cylinder is a trusted solution for heavy-duty tasks. From construction equipment to material handling machinery, standard heavy rod hydraulic cylinders are the workhorse to ensure optimal performance and productivity.

Heavy Rod Hydraulic Cylinder Key Characteristics:

1. Robust Construction: Standard heavy rod hydraulic cylinders feature a robust design and high-quality materials such as steel or alloys to withstand heavy loads and harsh operating environments. Its rugged construction ensures long-lasting durability and resistance to wear.

2. Powerful Performance: This heavy rod hydraulic cylinder offers impressive force and power output with its large piston diameter and high-pressure capability. Its ability to lift, push, or pull heavy objects makes it ideal for demanding industrial applications.

3. Versatile Applications: Standard heavy rod hydraulic cylinders suit various industries, including construction, mining, agriculture, and manufacturing. Its versatility enables it to be integrated into multiple devices and systems, providing reliable performance in different applications.

Standard Heavy Rod Hydraulic Cylinder Parameter:

Standardne raske varda hüdrosilinder Kasutamise meetod:

Mounting and Connection: Install the standard heavy-rod hydraulic cylinder safely into position using appropriate brackets or fixtures. During installation, ensure correct alignment and stability. Follow the manufacturer’s instructions and guidelines to connect hydraulic lines to cylinder ports.

Hydraulic System Integration: The cylinder is integrated into the hydraulic system by connecting it to a suitable hydraulic pump or power unit. Ensure cylinder specifications and operating requirements are met.

Control and Operation: Use the control valve to adjust the hydraulic oil flow into and out of the cylinder. Adjust the control Settings according to the desired linear motion and force output. Test the movement of the cylinder to verify its function and responsiveness.

Standardne raske varda hüdrosilinder Maintenance:

Regular maintenance is essential to maximize the lifespan and performance of the Standard Heavy Rod Hydraulic Cylinder. Here are some maintenance guidelines:

Periodic Inspection: Perform routine inspections to identify signs of wear, damage, or leaks. Check for abnormalities in cylinder blocks, piston rods, seals, and other components. Resolve any issues promptly to prevent further injury or operational inefficiencies.

Lubrication: Apply the recommended lubricant to the moving parts of the cylinder, including tie rods and seals. Regular lubrication minimizes friction, reduces wear, and ensures smooth operation. Follow the manufacturer’s guidelines for lubrication intervals and appropriate lubricant types.

Seal Replacement: If seals are found to be deteriorating or leaking, replace seals with genuine parts approved by the manufacturer. Damaged or worn seals can compromise cylinder performance and lead to hydraulic oil leakage.

Cleaning: Clean cylinders by removing dirt, debris, and other contaminants. Before reassembling, use a non-abrasive cleaner and make sure all parts are arid. Regular cleaning promotes optimal performance and prevents premature wear or damage.

How To Check If Hydraulic Cylinder Is Leaking Internally?

To check if a hydraulic cylinder is leaking internally, you can perform the following steps:

- Visual Inspection: Start by visually inspecting the exterior of the hydraulic cylinder. Look for oil or hydraulic fluid around the cylinder body, rod, or seals. External leaks may indicate internal leakage as well.

- Cylinder Operation: Operate the hydraulic cylinder through its full range of motion. Pay attention to any unusual sounds, vibrations, or jerky movements that may indicate internal leakage. If the cylinder operates smoothly without any unusual behavior, it doesn’t necessarily rule out internal leakage, but it suggests that the issue may be less severe.

- External Leakage Test: Wipe the cylinder clean and then visually inspect it for any fresh oil or hydraulic fluid after a period of inactivity. If you notice new oil or fluid on the cylinder’s exterior, it could indicate internal leakage.

- Pressure Drop Test: Perform a pressure drop test to check for internal leakage. Follow these steps:a. Ensure the hydraulic system is depressurized and the cylinder is in a safe position.b. Disconnect the hydraulic lines from the cylinder, carefully capping or plugging the openings to prevent fluid loss.c. Apply pressure to the appropriate port of the cylinder using a hand pump or another hydraulic power source.

d. Monitor the pressure gauge. If the pressure drops significantly over a short period, it suggests internal leakage within the cylinder.

e. Repeat the test on both sides of a double-acting cylinder if applicable.

- Rod Extension Test: Extend the cylinder rod partially or entirely, and then inspect the exposed portion of the rod for any signs of hydraulic fluid. If you notice oil or juice on the rod, it may indicate internal leakage past the rod seals.

- Cylinder Disassembly: If you suspect internal leakage but haven’t identified it through the previous steps, you may need to disassemble the cylinder for a detailed inspection. Disassembling the cylinder allows you to examine the piston, seals, and other internal components for signs of wear, damage, or contamination.

Tehase võimekus ja suutlikkus:

(1) Kokkupanek

Meil on esmaklassiline sõltumatu teadus- ja arendustegevuse montaažiplatvorm. Hüdrosilindrite tootmistöökojas on neli poolautomaatset tõstesilindrite koosteliini ja üks automaatne kallutussilindrite koosteliin, mille kavandatud aastane tootmisvõimsus on 1 miljon tükki. Spetsiaalsete silindrite töökoda on varustatud erinevate spetsifikatsioonidega poolautomaatse puhastusmontaažisüsteemiga, mille kavandatud aastane tootmisvõimsus on 200 000 ja mis on varustatud kuulsate CNC-töötlemisseadmete, mehaanilise töötlemise keskuse, suure täpsusega silindrite töötlemise eriseadmete, robotkeevitusmasina, automaatse puhastusmasina, automaatse silindri kokkupanemise masina ja automaatse värvimise tootmisliiniga. Olemasolevad kriitilised seadmed rohkem kui 300 komplekti (komplekti). Seadmete ressursside optimaalne jaotamine ja tõhus kasutamine tagavad toodete täpsusnõuded ja vastavad toodete kvaliteedinõuetele.

(2) Töötlemine

Töödeldav töökoda on varustatud kohandatud kallutatud rööpse treipingi keskuse, mehaanilise keskuse, kiire lihvimismasina, keevitusroboti ja muude seotud seadmetega, mis suudavad töödelda silindritorusid, mille maksimaalne siseläbimõõt on 400 mm ja maksimaalne pikkus on 6 meetrit.

(3) Keevitamine

(4) Värvimine ja katmine

Väikese ja keskmise suurusega silindri automaatse veepõhise värvipinnakattega liinide abil, et saavutada automaatne robotlaadimine ja mahalaadimine ning automaatne pihustamine, projekteerimisvõimsus 4000 tükki vahetuse kohta;

Meil on ka poolautomaatne suurte balloonide värvimise tootmisliin, mis töötab jõukettaga ja mille projekteerimisvõimsus on 60 kasti ühe vahetuse kohta.

(5) Testimine

Meil on esmaklassilised kontrolliseadmed ja katsestendid, et tagada silindri jõudlus vastavus nõuetele.

We are one of the best heavy rod hydraulic cylinder manufacturers. We can offer wide heavy rod hydraulic cylinder stock. We also provide corresponding põllumajanduslikud käigukastid. Oleme eksportinud oma tooteid klientidele üle kogu maailma ja teeninud hea maine tänu meie suurepärasele tootekvaliteedile ja müügijärgsele teenindusele. Me tervitame soojalt kliente nii kodus kui ka välismaal, et võtta meiega ühendust, et pidada läbirääkimisi äri, vahetada teavet ja teha meiega koostööd!

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Kuidas töötab kahveltõstuki hüdrosilinder?

Hüdrosilindri kasutamine: