Mobile Crane Steering Cylinder

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

Mobile Crane Steering Cylinder

The mobile crane steering cylinder is a vital component that plays a crucial role in ensuring precise steering control and maneuverability of mobile cranes during lifting operations. Designed specifically for mobile cranes, this hydraulic cylinder enables operators to navigate the crane accurately, enhancing safety and efficiency on construction sites and industrial settings.

The mobile crane steering cylinder is an essential component that ensures precise steering control and maneuverability in mobile crane lifting operations. With its robust construction, hydraulic power, and optimal steering performance, this hydraulic cylinder enables operators to navigate mobile cranes accurately and confidently. Following proper usage methods and adhering to recommended maintenance practices, operators can maximize the lifespan and reliability of the mobile crane steering cylinder, leading to safe and efficient lifting operations. Choose this indispensable hydraulic component to achieve precision steering and enhance maneuverability in your mobile crane operations.

Mobile Crane Steering Cylinder Key Characteristics:

- Robust Construction and Durability:

- The mobile crane steering cylinder is constructed with high-quality materials, providing exceptional strength and durability.

- It is designed to withstand heavy loads, shocks, and harsh environmental conditions, ensuring reliable performance even in demanding work environments.

- Hydraulic Control and Precision:

- This cylinder operates through a hydraulic control system, allowing for precise steering control of the mobile crane.

- The hydraulic control ensures smooth and responsive steering, enabling operators to maneuver the crane accurately and precisely.

- Optimal Steering Performance:

- The mobile crane steering cylinder is engineered to deliver optimal steering performance, allowing operators to navigate the crane effortlessly.

- It provides the necessary force to turn the wheels, ensuring smooth and controlled steering movements.

- Enhanced Safety and Maneuverability:

- Precise steering control is crucial for ensuring the safety and maneuverability of mobile cranes.

- The mobile crane steering cylinder enables operators to control the crane’s movement, minimizing the risk of accidents and ensuring safe and efficient operation.

Mobile Crane Steering Cylinder Parameter:

| Product Name | Mobile Crane Steering Cylinder |

| Features: | Steering system for crane chassis tires |

| Bore diameter: | 63mm~200mm |

| Rod diameter: | 36mm~140mm Stroke≤1000mm |

| Pressure: | Maximum 35MPa |

| Telescopic Cylinder Applications: | Mobile Crane |

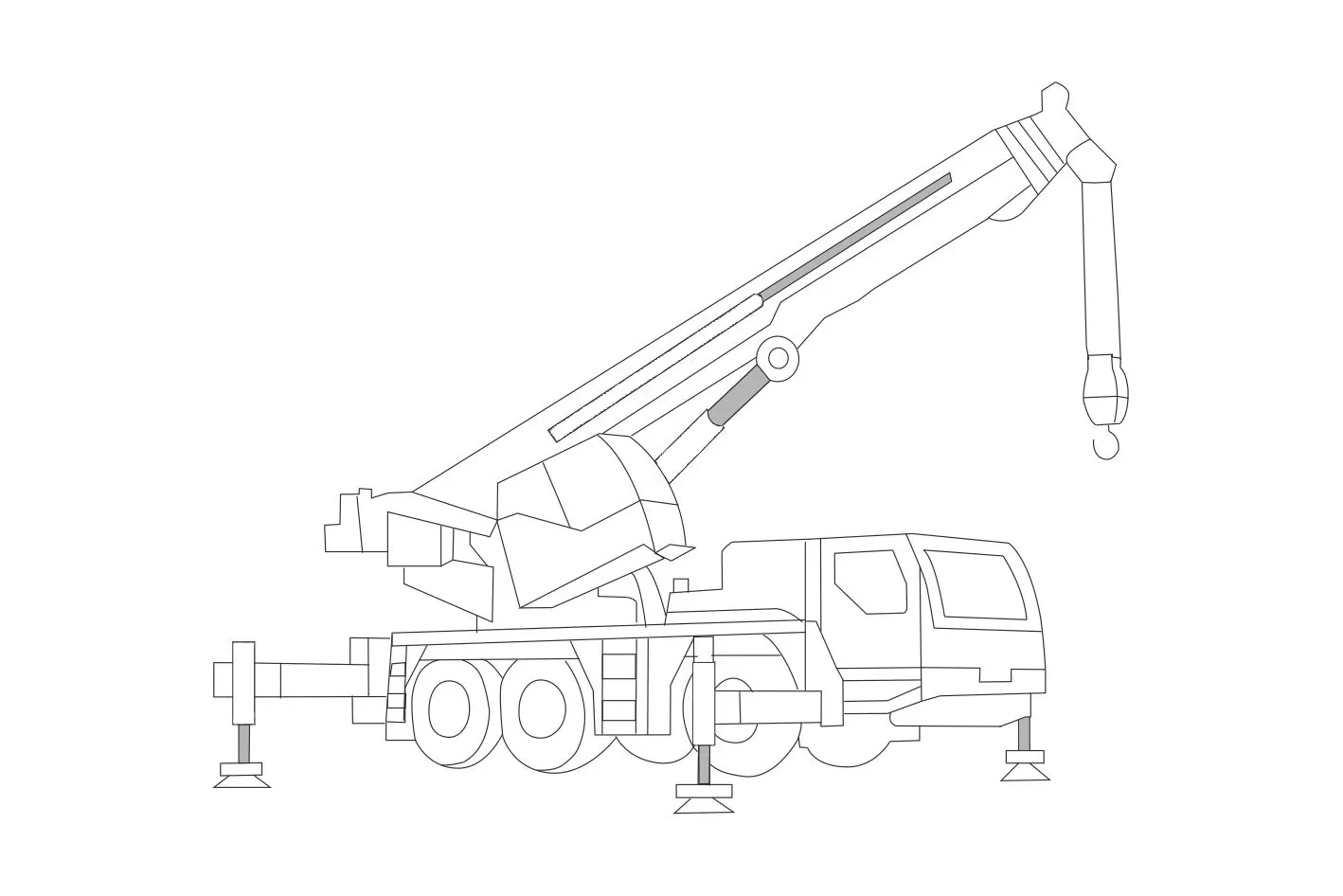

Mobile Crane Identification Diagram:

Usage Method Of Mobile Crane Steering Cylinder:

- Familiarize with Controls and Safety Guidelines:

- Before operating the mobile crane, operators should familiarize themselves with the crane’s steering controls and safety guidelines.

- Ensure all safety procedures and precautions are followed to ensure safe lifting operations.

- Steering Control:

- Use the steering wheel or joystick to control the steering of the mobile crane.

- The Mobile Crane Steering Cylinder will translate the input from the controls into the necessary force to turn the wheels.

- Smooth Steering Movements:

- Maintain a steady and controlled steering input to achieve smooth and precise steering movements.

- Avoid abrupt or jerky steering actions, which can affect stability and compromise safety.

- Adapt to Terrain and Load Conditions:

- Adjust the steering input based on the terrain and load conditions.

- Be mindful of the crane’s center of gravity and make necessary steering adjustments to ensure stability and balance.

What Is Charge Pressure In Hydraulic System?

In a hydraulic system, the charge pressure refers to the pressure level maintained in the system’s accumulator or charge pump. It is typically lower than the operating pressure used for powering actuators or performing work. The charge pressure serves several important purposes in a hydraulic system:

- Energy Storage: In systems that utilize an accumulator, the charge pressure is responsible for storing hydraulic energy. When the system’s pump exceeds the required flow rate, the excess fluid is directed to the accumulator, which compresses a gas (such as nitrogen) or uses a spring mechanism to store energy in the pressurized fluid. This stored energy can be released later to provide instantaneous power during peak demand or to supplement the pump’s output.

- System Readiness: The charge pressure ensures the system is ready for immediate operation. The hydraulic system is primed and prepared to respond quickly to the operator’s commands or sudden load changes by maintaining a consistent pressure level. This reduces response time and enables rapid actuator movement, enhancing the system’s overall performance.

- Leakage Compensation: Hydraulic systems may experience minor internal or external leaks over time. The charge pressure compensates for these leaks by replenishing the lost fluid volume. This ensures that an adequate supply of hydraulic fluid is available for proper system operation, preventing any loss of functionality or reduction in performance due to leaks.

- System Stability: The charge pressure contributes to system stability by minimizing the potential for cavitation and maintaining a positive pressure environment. Cavitation occurs when the pressure drops below the vapor pressure of the hydraulic fluid, causing the formation and subsequent collapse of vapor bubbles. This can lead to damage to system components and a decrease in overall performance. Maintaining a sufficient charge pressure reduces the risk of cavitation, ensuring stable and reliable operation.

Tehase võimekus ja suutlikkus:

(1) Kokkupanek

Meil on esmaklassiline sõltumatu teadus- ja arendustegevuse montaažiplatvorm. Hüdrosilindrite tootmistöökojas on neli poolautomaatset tõstesilindrite koosteliini ja üks automaatne kallutussilindrite koosteliin, mille kavandatud aastane tootmisvõimsus on 1 miljon tükki. Spetsiaalsete silindrite töökoda on varustatud erinevate spetsifikatsioonidega poolautomaatse puhastusmontaažisüsteemiga, mille kavandatud aastane tootmisvõimsus on 200 000 ja mis on varustatud kuulsate CNC-töötlemisseadmete, mehaanilise töötlemise keskuse, suure täpsusega silindrite töötlemise eriseadmete, robotkeevitusmasina, automaatse puhastusmasina, automaatse silindri kokkupanemise masina ja automaatse värvimise tootmisliiniga. Olemasolevad kriitilised seadmed rohkem kui 300 komplekti (komplekti). Seadmete ressursside optimaalne jaotamine ja tõhus kasutamine tagavad toodete täpsusnõuded ja vastavad toodete kvaliteedinõuetele.

(2) Töötlemine

Töödeldav töökoda on varustatud kohandatud kallutatud rööpse treipingi keskuse, mehaanilise keskuse, kiire lihvimismasina, keevitusroboti ja muude seotud seadmetega, mis suudavad töödelda silindritorusid, mille maksimaalne siseläbimõõt on 400 mm ja maksimaalne pikkus on 6 meetrit.

(3) Keevitamine

(4) Värvimine ja katmine

Väikese ja keskmise suurusega silindri automaatse veepõhise värvipinnakattega liinide abil, et saavutada automaatne robotlaadimine ja mahalaadimine ning automaatne pihustamine, projekteerimisvõimsus 4000 tükki vahetuse kohta;

Meil on ka poolautomaatne suurte balloonide värvimise tootmisliin, mis töötab jõukettaga ja mille projekteerimisvõimsus on 60 kasti ühe vahetuse kohta.

(5) Testimine

Meil on esmaklassilised kontrolliseadmed ja katsestendid, et tagada silindri jõudlus vastavus nõuetele.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding põllumajanduslikud käigukastid. Oleme eksportinud oma tooteid klientidele üle maailma ja teeninud hea maine tänu meie suurepärasele tootekvaliteedile ja müügijärgsele teenindusele. Me tervitame kliente kodus ja välismaal, et võtta meiega ühendust, et pidada läbirääkimisi äri, vahetada teavet ja teha meiega koostööd!

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Kuidas töötab kahveltõstuki hüdrosilinder?

Hüdrosilindri kasutamine: