Mining Dump Lifting Cylinder Hydraulic On Trucks

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

Mining Dump Lifting Cylinder Hydraulic On Trucks

The lifting cylinder of a mining dump truck is a vital component specifically engineered for these vehicles. This powerful hydraulic cylinder is responsible for raising and lowering the truck’s dump bed, facilitating efficient loading and unloading of materials during mining operations.

Designed for robustness and high lifting capacity, the mining dump truck lifting cylinder plays a crucial role in enhancing the efficiency and productivity of mining activities. Its precise control allows for seamless material handling, which reduces downtime and maximizes output.

To ensure the longevity and reliable performance of this hydraulic cylinder, operators should follow proper usage guidelines and adhere to recommended maintenance practices. Opt for this high-performance lifting cylinder to boost your mining dump truck’s capabilities and optimize your mining operations.

Mining Dump Lifting Cylinder Hydraulic On Trucks Parameter:

| Product Name | Mining Dump Lifting Cylinder Hydraulic On Trucks |

| Features: | Lift/lower the body for cargo dumping |

| Bore diameter: | 120mm~380mm |

| Rod diameter: | 90mm~350mm |

| Generally: | Two-stage or three-stage cylinder |

| Lifting Cylinder Applications: | Mining Dump Truck |

Mining Dump Truck Lifting Cylinder Key Characteristics:

Robust and Reliable Construction

The Mining Dump Truck Lifting Cylinder is designed for durability, made from high-quality materials and precision engineering to withstand the tough conditions of mining operations. It offers exceptional strength and reliability, enabling it to handle heavy loads and deliver consistent performance even in harsh environments.

High Lifting Capacity

This cylinder is engineered to provide substantial lifting capacity, allowing the mining dump truck to efficiently manage large volumes of materials. With impressive lifting power, it facilitates swift and reliable dumping, minimizing downtime and maximizing productivity on the job site.

Precise Control and Smooth Operation

The Mining Dump Truck Lifting Cylinder enables precise control over the raising and lowering of the dump bed, ensuring smooth and accurate movement. This feature allows operators to position the dump bed accurately, streamlining both loading and unloading operations.

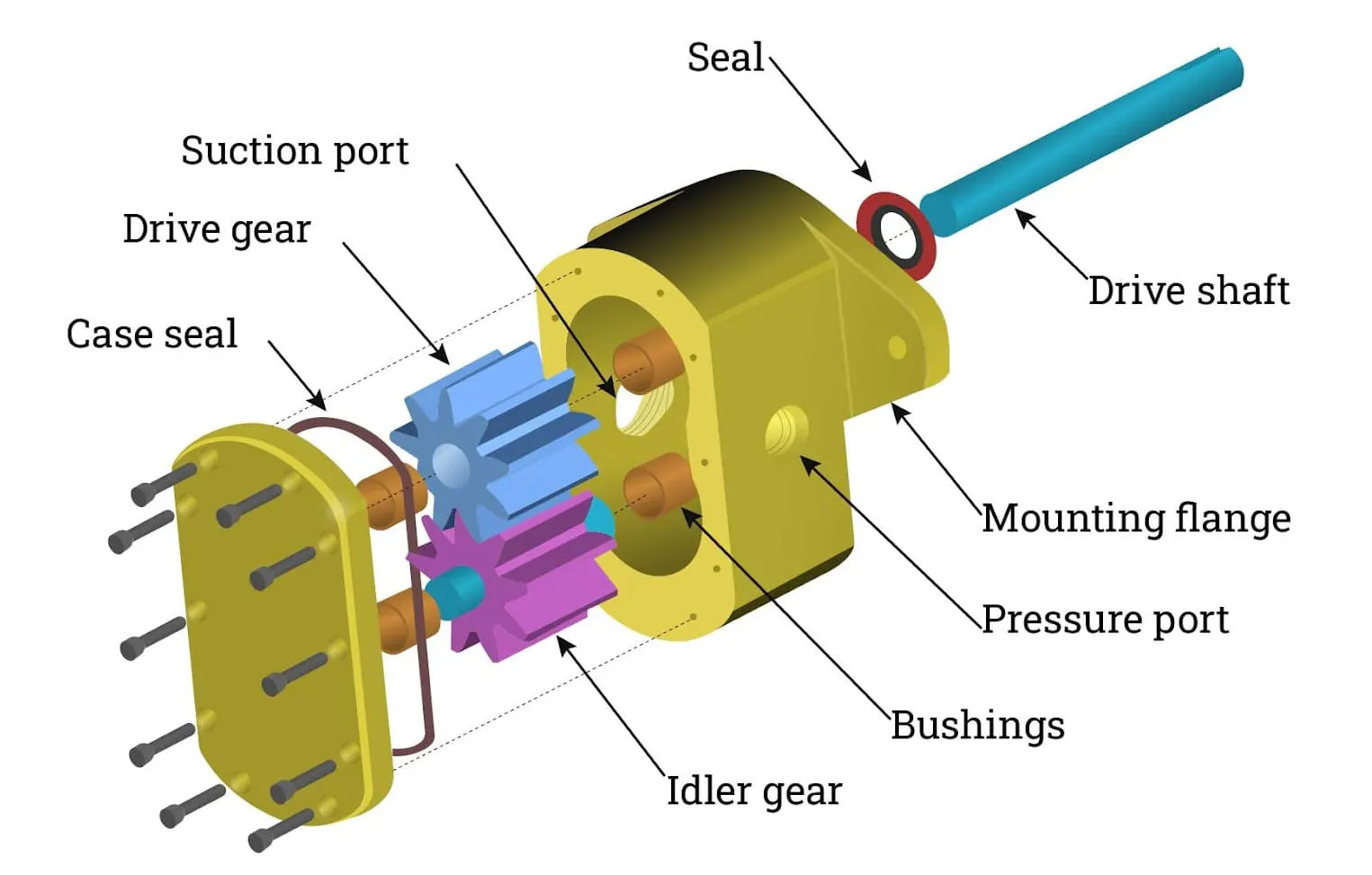

Mining Dump Lifting Cylinder Hydraulic On Trucks Identification Diagram:

How To Install Hydraulics On A Truck?

1. Gather Your Materials and Tools

Hydraulic Components:

Pump: The heart of your hydraulic system.

Cylinder: Converts hydraulic energy into mechanical force.

Hoses and Fittings: Essential for fluid transfer and connections.

Reservoir: Holds hydraulic fluid.

Tools You’ll Need:

Wrenches: For tightening connections.

Screwdrivers: For securing components.

Drill: If additional mounting holes are necessary.

Saw: For any adjustments or modifications.

Hydraulic Fluid: The lifeblood of your hydraulic system.

2. Plan the Installation

Choose Locations Wisely: Identify and mark ideal mounting spots for the pump, reservoir, and cylinder, ensuring easy access and optimal functionality.

Review Schematics: Study the system layout and connection diagrams specific to your truck to avoid any confusion during installation.

3. Install the Hydraulic Pump

Mount the Pump Securely: Fasten the pump to the truck frame or engine using appropriate brackets, ensuring it’s stable and secure.

Align with PTO: If applicable, connect the pump to the power take-off (PTO) for seamless power transfer from the engine.

4. Install the Hydraulic Reservoir

Position Strategically:Place the reservoir near the pump for easy access during maintenance and fluid checks.

Secure It Well: Use sturdy brackets or bolts to firmly attach the reservoir to the truck frame, preventing movement during operation.

5. Install the Hydraulic Cylinder

Mount the Cylinder: Secure the hydraulic cylinder in your desired location, such as the dump bed or other operational areas.

Ensure Stability: Check that it’s tightly attached to the frame or bed to handle the stresses of operation without shifting.

6. Run Hydraulic Hoses

Connect Hoses: Attach hoses from the pump to the cylinder and reservoir, ensuring they are routed away from moving parts and heat sources.

Use Proper Fittings: Double-check all connections to ensure they’re tight and leak-free, using thread sealant if necessary.

7. Connect Control Valves

Install Control Valves Conveniently: Position control valves in the cab or near the driver’s seat for easy access while driving.

Connect to Hydraulic Lines: Attach the valves to the hoses leading to the cylinder, ensuring clear and unobstructed pathways for fluid flow.

8. Fill the Hydraulic System

Add Hydraulic Fluid: Carefully fill the reservoir with the appropriate hydraulic fluid, following manufacturer specifications.

Check for Leaks: Thoroughly inspect all connections and fittings for any signs of leakage, tightening as needed.

9. Test the System

Operate the Controls: Engage the hydraulic system to test its functionality, ensuring smooth operation without any hitches.

Monitor Performance: Watch for leaks and listen for unusual sounds during operation. Make adjustments as necessary for optimal performance.

10. Final Adjustments

Secure All Components: Go through each component to ensure everything is tightly fastened and secure.

Make Necessary Adjustments: Fine-tune any parts for improved performance, ensuring your hydraulic system is ready for action.

How To Check Hydraulic Fluid On Dump Truck?

1. Safety First

Park the Dump Truck: Ensure the truck is on a flat, stable surface.

Engage the Parking Brake: Activate the parking brake and turn off the engine.

2.Locate the Hydraulic Reservoir

Find the hydraulic fluid reservoir, typically marked and located near the hydraulic system components.

3.Inspect the Fluid Level

Using a Dipstick: If there’s a dipstick, remove it, wipe it clean with a cloth, and reinsert it to check the level.

Using a Sight Glass: If the reservoir has a sight glass, simply observe the fluid level directly.

4.Check Fluid Condition

Assess the fluid’s color and clarity. Hydraulic fluid should be clean and clear. If it appears dark or contains debris, it may need to be replaced.

5. Add Hydraulic Fluid if Necessary

If the fluid level is low, add the manufacturer-recommended hydraulic fluid until it reaches the proper level.

6. Check for Leaks

Inspect the area around the reservoir and hoses for any signs of leaks or damage.

7. Close the Reservoir

If you added fluid, ensure the reservoir cap is securely replaced.

8. Test the System

Start the truck and briefly operate the hydraulic system to circulate the fluid. Then, recheck the fluid level to ensure it remains at the correct level.

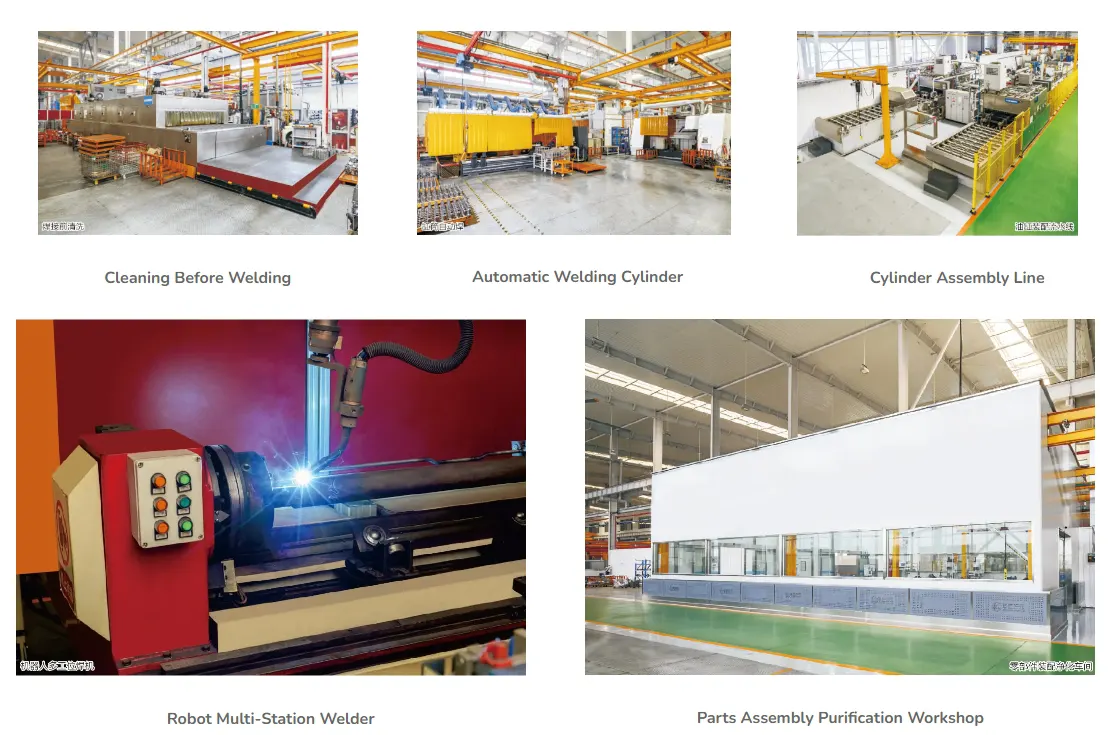

Tehase võimekus ja suutlikkus:

(1) Kokkupanek

Our facility boasts a top-tier independent research and development assembly platform dedicated to hydraulic cylinder production. We operate four semi-automatic lifting cylinder assembly lines and one fully automatic tilt cylinder assembly line, with an impressive annual production capacity of 1 million cylinders.

In our specialized cylinder workshop, we utilize a semi-automatic cleaning assembly system designed for various specifications, capable of producing 200,000 cylinders annually. Our workshop is equipped with advanced CNC machining equipment, a machining center, high-precision cylinder processing tools, robot welding machines, automatic cleaning systems, and an automated cylinder assembly line. Additionally, we have a fully automated painting production line.

With over 300 pieces of critical equipment, our optimal resource allocation ensures that we meet the strict accuracy and quality standards required by our clients. This commitment to efficiency and precision positions us as a leader in the hydraulic cylinder industry.

(2) Töötlemine

Our machining shop features state-of-the-art equipment, including a customized inclined rail turning center, a precision machining center, a high-speed honing machine, and advanced welding robots. This sophisticated setup enables us to efficiently process cylinder tubes with a maximum inner diameter of 400mm and a length of up to 6 meters.

With our cutting-edge technology, we ensure high-quality machining that meets the diverse needs of hydraulic cylinder production.

(3) Keevitamine

(4) Painting & Coating

Our facility features advanced automatic water-based paint coating lines specifically designed for small and medium-sized cylinders. These lines utilize robotic technology for efficient loading, unloading, and spraying, achieving a remarkable production capacity of 4,000 pieces per shift.

In addition, we operate a semi-automatic paint production line for large cylinders, powered by a robust power chain, with a designed capacity of 60 cases per shift. This combination of automation and efficiency ensures high-quality finishes for all our hydraulic cylinders.

(5) Testimine

Meil on esmaklassilised kontrolliseadmed ja katsestendid, et tagada silindri jõudlus vastavus nõuetele.

We are a renowned manufacturer of hüdrosilindrid, recognized as one of the best in the industry. Our extensive product line includes a wide range of hydraulic cylinders tailored to meet various applications. In addition to hydraulic cylinders, we also provide high-quality agricultural gearboxes, ensuring our customers have access to comprehensive solutions for their machinery needs.

With a commitment to excellence, we have successfully exported our products to clients worldwide, earning a strong reputation for superior product quality and exceptional after-sales service. Our dedication to customer satisfaction has positioned us as a trusted partner in both domestic and international markets.

Why Choose Us?

Professional Expertise: Our team comprises industry professionals with extensive knowledge and experience in hydraulic systems, ensuring that we deliver top-notch products and services.

International Certifications: We adhere to strict quality standards and hold various international certifications, demonstrating our commitment to delivering reliable and safe hydraulic solutions.

Custom Solutions: We understand that each customer’s needs are unique. That’s why we offer customized hydraulic cylinders and gearboxes tailored to meet specific requirements.

Advanced Production Equipment: Our state-of-the-art manufacturing facilities utilize the latest technology and equipment, enabling us to produce high-quality products efficiently.

Comprehensive After-Sales Support: Our commitment to our customers extends beyond the sale. We provide ongoing support and maintenance services to ensure optimal performance of our products.

We invite customers from around the globe to reach out to us for business negotiations, information exchange, and collaboration opportunities. Together, we can achieve greater success in the hydraulic industry!

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Kuidas töötab kahveltõstuki hüdrosilinder?

Hüdrosilindri kasutamine: