Lift Hydraulic Cylinders for Forward Moving Forklift

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

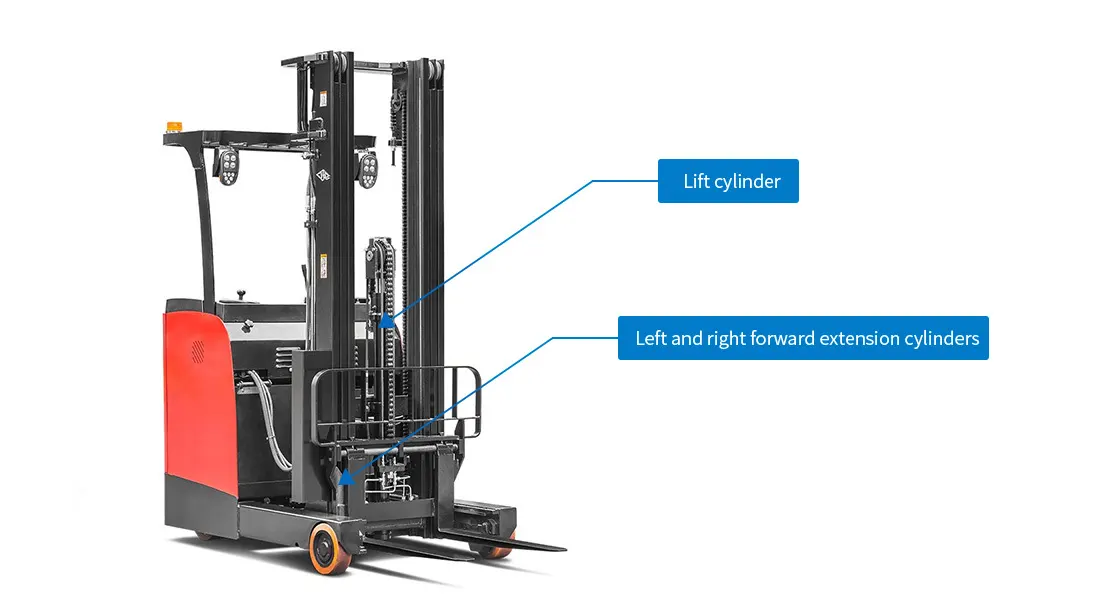

Lift Hydraulic Cylinders For Forward Moving Forklift

Lift hydraulic cylinders are essential components of forward moving forklifts, providing the necessary lifting power to handle heavy loads efficiently. These cylinders convert hydraulic pressure into mechanical force, enabling forklifts to raise and lower loads with precision. Their robust design and reliable performance make them indispensable in various industrial applications, enhancing productivity and safety.

Lift hydraulic cylinders are vital for the efficient operation of forward moving forklifts. Their high load capacity, durable construction, and smooth operation make them indispensable in various industrial applications. By understanding their features, proper usage methods, and maintenance requirements, operators can maximize the performance and safety of their equipment, ultimately enhancing productivity in material handling tasks. Investing in high-quality lift hydraulic cylinders ensures reliable and efficient operations, crucial for success in any business.

Lifting Hydraulic Cylinders of Pallet Stacker Truck

Lift Hydraulic Cylinders for Forward Moving Forklift Technical Specifications:

Function: To achieve the lifting and lowering action of the gantry

Cylinder diameter: 45mm-75mm

Rod diameter: 45mm-65mm

Travel: 500mm-3980mm

Maximum pressure: 21MPa

Maximum thrust: 93KN

Forward Moving Forklift Cylinder Series:

Key Features of Lift Hydraulic Cylinders for Forward Moving Forklift:

- Suur kandevõime: Lift hydraulic cylinders are specifically designed to handle substantial weights, providing the necessary strength to lift heavy loads safely. This capability is crucial in preventing accidents, as it ensures that the forklift operates within its load limits. By facilitating efficient material handling, these cylinders enhance productivity and reduce the time required for lifting tasks, allowing operators to focus on other essential activities.

- Durable Construction: Constructed from high-strength materials, lift hydraulic cylinders resist wear and tear even in the most demanding environments. Their robust design not only ensures long-lasting performance but also significantly minimizes the risk of mechanical failure. This durability translates into lower maintenance costs and less downtime, making these cylinders a cost-effective choice for businesses seeking reliable equipment that withstands the rigors of daily use.

- Sujuv toimimine: The hydraulic system within these cylinders delivers consistent and smooth lifting and lowering actions, which is vital for maintaining load stability. By minimizing jolts and vibrations during operation, lift hydraulic cylinders enhance safety for both the operator and surrounding personnel. This smooth operation also contributes to better control when handling sensitive or fragile materials, ensuring they remain secure throughout the lifting process.

- Compact Design: Lift hydraulic cylinders come in a variety of sizes to accommodate different forklift models, allowing for seamless integration into existing equipment. This compact design does not compromise the vehicle’s maneuverability, enabling operators to navigate tight spaces with ease. The adaptability of these cylinders ensures that they can be used across various applications without requiring significant modifications to the forklift.

- Mitmekülgsed rakendused: These hydraulic cylinders are suitable for a wide range of industries, including logistics, manufacturing, and construction. Their versatility makes them adaptable to various operational needs, from warehouse stacking and retrieval to heavy lifting on construction sites. This broad applicability allows businesses to leverage lift hydraulic cylinders in multiple settings, optimizing their material handling processes and improving overall efficiency.

Use Cases for Lift Hydraulic Cylinders for Forward Moving Forklift:

Lift hydraulic cylinders play a crucial role in enhancing the functionality and efficiency of forward moving forklifts. Here are some key use cases that highlight their importance across various industries:

1. Warehouse Operations

In warehouse settings, lift hydraulic cylinders enable forklifts to stack and retrieve pallets at varying heights. This capability optimizes vertical storage space and allows for quick access to inventory, streamlining operations and improving overall efficiency.

2. Loading and Unloading

Lift hydraulic cylinders facilitate the loading and unloading of goods from trucks and containers. By allowing forklifts to raise and lower loads smoothly, they minimize the risk of damage to products and reduce the time spent on these tasks, enhancing overall productivity.

3. Order Picking

In environments where order picking is essential, hydraulic cylinders allow forklifts to position themselves accurately at the required height to access specific items. This functionality improves accuracy in fulfilling orders and increases overall operational efficiency.

4. Cross-Docking

In cross-docking operations, where products are transferred directly from inbound to outbound transportation, lift hydraulic cylinders help move pallets quickly and efficiently. This reduces handling time and ensures a smooth flow of goods through the supply chain.

5. Manufacturing Facilities

In manufacturing environments, lift hydraulic cylinders assist in transporting raw materials and finished products between different production stages. Their ability to lift heavy items safely enhances workflow and productivity on assembly lines.

Looking for heavy-duty forklift cylinders? Check out our Heavy-Duty Hydraulic Cylinders.

Forklift Cylinder Production Area:

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line with a designed annual production capacity of million pieces. The special cylinder workshop has semi-automatic cleaning and assembly systems of various specifications with a designed annual production capacity of 200000 pieces. It is equipped with famous brand CNC machining equipment, machining centers, special equipment for high-precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of key equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

The machining shop is equipped with custom-made tilt guiderailturning centers, machining centers, high-speed honing machines, welding robots, and other relevant equipment, which can handle the machining work of cylinder tubes with 400mm Max ID and 6 meters of Max length.

We have a fully automatic water-based paint coating line for small and medium cylinders, which realizes automatic loading and unloading and automatic spraying robots with a designed production capacity of 4000 places per shift. We have another semi-automatic painting line for large-scale cylinders driven by a power chain, and the design capacity is 60 crates per shift.

To further improve product performance and establish the leadership position of our hydraulic cylinders in the industry, our company and zjimee jointly established a Comprehensive performance laboratory of hydraulic cylinders, hydraulic valves, and hydraulic pumps; the lab is computer-assisted testing using electro-hydraulic technology, the test conditions are preset by a computer which improves the test accuracy and system versatility, and the experimental data.

The automatic collection is realized through the application of sensors, and the output data, such as the internal leakage and load efficiency of the cylinder or the vale, are directly processed by the computer and converted to standard units (ml/min%). At the same time, to ensure the working safety of the hydraulic system, the state monitoring function is carried out for key performance parameters such as”oil temperature monitoring, liquid level monitoring, filter device monitoring,” etc. Among them, the hydraulic cylinder test stand can test the performance of the “load

efficiency “and” internal leakage” by readings. At the same time, it is equipped with a grating ruler measuring instrument that meets the requirements of all test items of hydraulic cylinder products according to the national standard.

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Kuidas töötab kahveltõstuki hüdrosilinder?

Hüdrosilindri kasutamine: