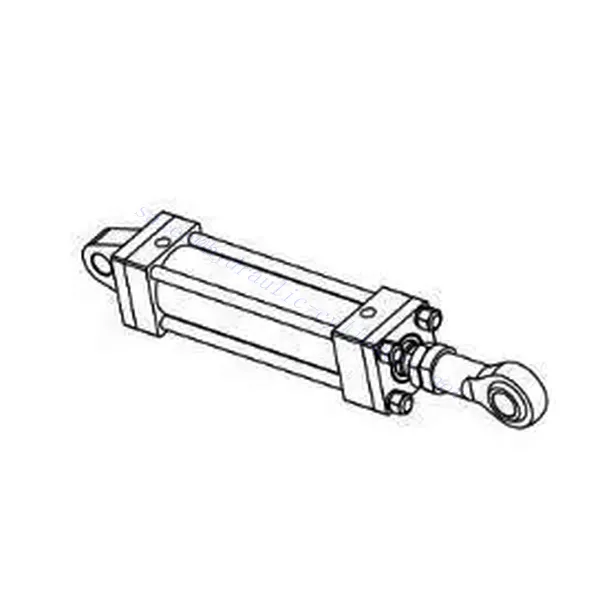

CA Monaural Type Gksk Joint Earring Connector Heavy Rod Hydraulic Cylinder

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

CA Monaural Type Gksk Joint Earring Connector Heavy Rod hüdrosilinder

The CA monaural type Gksk Articulated Earring Connector Heavy Rod hydraulic cylinder is a cutting-edge hydraulic element for heavy industrial applications. With its rugged construction, advanced features, and precise functionality, this hydraulic cylinder is designed to provide optimal power, reliability, and performance. Whether you need to lift, push or pull heavy loads, the CA Mono type Gksk Articulated Earring Connector heavy rod hydraulic cylinder can handle the most challenging tasks with ease.

Essential Characteristics Of Heavy Rod Hydraulic Cylinder:

Vastupidav konstruktsioon: The CA monaural type Gksk hinged earring connector heavy rod hydraulic cylinder provides enhanced stability and motion control. The single rod extension ensures precise positioning and smooth operation, minimizing the risk of misalignment or deflection.

Monaural Type Design: The CA monaural type Gksk articulated earring connector heavy rod hydraulic cylinder provides enhanced stability and control of movement. The single rod extension ensures precise positioning and smooth operation, minimizing the risk of misalignment or deflection.

Gksk Joint Earring Connector: Equipped with a Gksk articulated earring connector, this hydraulic cylinder provides a convenient and safe connection to the hydraulic system. Connectors ensure reliable fluid transfer and minimize the risk of leakage or disconnection during operation, providing a worry-free experience.

Heavy Rod and High Force Output: The heavy rod design of this hydraulic cylinder, combined with its advanced hydraulic system, allows for exceptional force output. It can produce significant power, making it suitable for applications that require a lot of power and lifting capacity.

CA Monaural Type Gksk Joint Earring Connector Heavy Rod Hydraulic Cylinder Parameter:

CA Monaural Type Gksk Joint Earring Connector Heavy Rod hüdrosilinder Kasutamise meetod:

Mounting: First, securely install the CA monaural Gksk articulated earring connector heavy rod hydraulic cylinder using the appropriate mounting brackets or fixtures. Ensure proper alignment and stability during installation to prevent cylinder misalignment or excessive stress.

Hydraulic System Integration: Follow the manufacturer’s instructions and guidelines to connect the hydraulic line to the Gksk knuckle earring connector of the cylinder. The cylinder is integrated into the hydraulic system by clicking it to a suitable pump or power unit. Ensure cylinder specifications and operating requirements are met.

Control and Operation: The control valve in the hydraulic system regulates the flow of hydraulic oil into and out of the cylinder. Adjust the control Settings to achieve the desired linear motion and force output. Test the movement of the cylinder to verify its function and responsiveness.

CA Monaural Type Gksk Joint Earring Connector Heavy Rod hüdrosilinder Maintenance:

Regular maintenance is essential to ensure optimal performance and longevity of the CA Monaural Type Gksk Joint Earring Connector Heavy Rod Hydraulic Cylinder. Follow these maintenance guidelines:

Regular Inspection: Conduct routine inspections to identify signs of wear, damage, or leaks. Inspect the cylinder body, rod, seals, and other components for abnormalities. Address any issues promptly to prevent further injury or operational inefficiencies.

Lubrication: Apply the recommended lubricant to the moving parts of the cylinder, including tie rods and seals. Regular lubrication minimizes friction, reduces wear, and ensures smooth operation. Use the appropriate lubricant type according to the manufacturer’s lubrication interval guidelines.

Seal Replacement: If seals are found to be deteriorating or leaking, replace seals with genuine parts approved by the manufacturer. Damaged or worn seals can compromise the cylinder’s performance and lead to hydraulic oil leakage.

Cleaning: Clean cylinders by removing dirt, debris, and other contaminants. Before reassembling, use a non-abrasive cleaner and make sure all parts are arid. Regular cleaning promotes optimal performance and prevents premature wear or damage.

How Much Does It Cost To Rebuild A Hydraulic Cylinder?

The cost to rebuild a hydraulic cylinder can vary depending on several factors, including the size and type of the cylinder, the extent of the damage or wear, the availability of replacement parts, and the labor costs in your location. It’s important to note that rebuilding a hydraulic cylinder requires expertise and specialized tools, so it is often recommended to have the work done by a professional hydraulic repair service.

When considering the cost of rebuilding a hydraulic cylinder, you should take into account the following potential expenses:

- Labor Costs: The time and expertise required to disassemble, inspect, repair, and reassemble the cylinder will contribute to the overall cost. Labor rates can vary depending on the location and the specific repair service.

- Replacement Parts: If any components within the cylinder need to be replaced, such as seals, bearings, or rods, the cost of these parts will add to the total expense. The availability and price of replacement parts vary depending on the cylinder’s make and model.

- Machining or Honing: In some cases, the cylinder may require machining or honing to restore the surfaces to their proper specifications. This additional process can add to the overall cost of the rebuild.

- Testing and Certification: Once the cylinder has been rebuilt, it may need to undergo testing and certification to ensure its performance and safety. These additional services may come with associated costs.

Tehase võimekus ja suutlikkus:

(1) Kokkupanek

Meil on esmaklassiline sõltumatu teadus- ja arendustegevuse montaažiplatvorm. Hüdrosilindrite tootmistöökojas on neli poolautomaatset tõstesilindrite koosteliini ja üks automaatne kallutussilindrite koosteliin, mille kavandatud aastane tootmisvõimsus on 1 miljon tükki. Spetsiaalsete silindrite töökoda on varustatud erinevate spetsifikatsioonidega poolautomaatse puhastusmontaažisüsteemiga, mille kavandatud aastane tootmisvõimsus on 200 000 ja mis on varustatud kuulsate CNC-töötlemisseadmete, mehaanilise töötlemise keskuse, suure täpsusega silindrite töötlemise eriseadmete, robotkeevitusmasina, automaatse puhastusmasina, automaatse silindri kokkupanemise masina ja automaatse värvimise tootmisliiniga. Olemasolevad kriitilised seadmed rohkem kui 300 komplekti (komplekti). Seadmete ressursside optimaalne jaotamine ja tõhus kasutamine tagavad toodete täpsusnõuded ja vastavad toodete kvaliteedinõuetele.

(2) Töötlemine

Töödeldav töökoda on varustatud kohandatud kallutatud rööpse treipingi keskuse, mehaanilise keskuse, kiire lihvimismasina, keevitusroboti ja muude seotud seadmetega, mis suudavad töödelda silindritorusid, mille maksimaalne siseläbimõõt on 400 mm ja maksimaalne pikkus on 6 meetrit.

(3) Keevitamine

(4) Värvimine ja katmine

Väikese ja keskmise suurusega silindri automaatse veepõhise värvipinnakattega liinide abil, et saavutada automaatne robotlaadimine ja mahalaadimine ning automaatne pihustamine, projekteerimisvõimsus 4000 tükki vahetuse kohta;

Meil on ka poolautomaatne suurte balloonide värvimise tootmisliin, mis töötab jõukettaga ja mille projekteerimisvõimsus on 60 kasti ühe vahetuse kohta.

(5) Testimine

Meil on esmaklassilised kontrolliseadmed ja katsestendid, et tagada silindri jõudlus vastavus nõuetele.

We are one of the best heavy rod hydraulic cylinder manufacturers. We can offer wide heavy rod hydraulic cylinder stock. We also provide corresponding põllumajanduslikud käigukastid. Oleme eksportinud oma tooteid klientidele üle kogu maailma ja teeninud hea maine tänu meie suurepärasele tootekvaliteedile ja müügijärgsele teenindusele. Me tervitame soojalt kliente nii kodus kui ka välismaal, et võtta meiega ühendust, et pidada läbirääkimisi äri, vahetada teavet ja teha meiega koostööd!

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Kuidas töötab kahveltõstuki hüdrosilinder?

Hüdrosilindri kasutamine: