Press

Hydraulic Cylinder

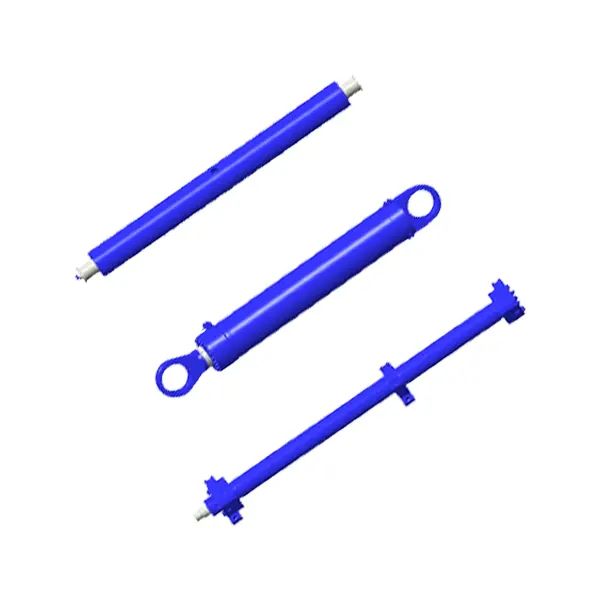

Press Hydraulic Cylinders for High-Force Industrial Applications

Reliable Solutions for Metal Forming, Forging, and Manufacturing

Press hydraulic cylinders are critical components for industrial pressing applications, delivering the high force needed for metal forming, forging, stamping, and other manufacturing processes. These cylinders are designed to provide precise control and immense power, with force capacities ranging from 100 to 10,000 tons, making them ideal for heavy-duty industrial tasks.

We specialize in durable press hydraulic cylinders that ensure reliability and safety under extreme pressures (up to 70 MPa). Built with high-strength alloy steel and advanced sealing technology, our cylinders resist wear, corrosion, and leaks, even in demanding environments. Whether you’re shaping metal sheets in a stamping press or forging components for the automotive industry, our press hydraulic cylinders deliver the performance and longevity you need to optimize your production process.

Press Hydraulic Cylinders For Sale

-

Press Master Cylinder

-

Press Side Cylinder

-

Press Return Cylinder

-

Press Lateral Shift Anvil Cylinder

-

Press Mobile Workbench Cylinder

-

Press Clamping Cylinder

-

Press Leveling Cylinder

-

Press Tilt Cylinder

-

Press Cushion Cylinder

-

Press Centering Cylinder

-

Press Front Side Shift Cylinder

-

Press Rear Side Shift Cylinder

Hydraulic Cylinder Production Area

We are a leading manufacturer specializing in hydraulic cylinders and hydraulic systems, dedicated to delivering high-tech solutions. Our company primarily serves OEMs in industries such as construction machinery, aerial work platforms, sanitation vehicles, wind power, and agricultural machinery. We offer a versatile range of hydraulic cylinders with inner diameters ranging from +20 to 500 mm, boasting an impressive annual design capacity of 1.2 million units.

Our state-of-the-art facilities include a provincial research institute, a high-tech R&D center, and a specialized hydraulic product testing laboratory. We utilize advanced equipment such as dedicated turning centers, high-speed cutting and polishing machines, automatic processing and welding systems, automatic cleaning and assembly lines, fully automated flexible painting lines, and intelligent logistics assembly lines. This comprehensive production and testing capability enables us to maintain a strong technological development capacity, ensuring our manufacturing processes and product quality meet advanced national standards.

Visit our VR hydraulic cylinder factory:

Production and Processing Workshop

Loading and Unloading Robots For Paint Lines

Product Testing Center

Cylinder Composite Machining Center

Automatic Cylinder Assembly Machine

With a robust quality assurance system in place, we have achieved ISO 9001 certification for quality management, as well as ISO 45001 for occupational health and safety, and ISO 14001 for environmental management. Our efficient, standardized processes and self-developed high-end equipment guarantee that our hydraulic cylinders are durable, pressure-resistant, leak-proof, and highly stable, with performance metrics that meet international benchmarks.

The “Huachang” series hydraulic cylinders are designed with a focus on structural integrity, reliable performance, and ease of maintenance. Their diverse structural forms allow for tailored solutions to meet specific customer needs. Coupled with our digital production management system, we respond quickly and effectively to customer requirements, ensuring that we exceed your expectations.

Choose us for high-quality hydraulic solutions that enhance your machinery’s performance and reliability.

Cylinder Assembly Line

Special Cylinder Testing Machine

Cylinder Inspection Area

Multi Station Welding Robot

Warehouse

Press Hydraulic Cylinders Application

Metal Processing,Automotive Parts Manufacturing,Plastic Molding,Rubber Processing

Press hydraulic cylinders are essential for metal processing tasks like stamping, forging, and shearing in industrial settings. Whether you’re shaping steel sheets for structural components, forging high-strength alloys, or cutting metal plates, our hydraulic cylinders for presses in metal processing ensure precision and immense force output. Capable of delivering up to 10,000 tons of force, they guarantee reliable performance under heavy loads.

hydraulic cylinder for press in metal processing

In automotive manufacturing, press hydraulic cylinders power the production of parts through stamping and forging processes. From forming car body panels like doors and hoods to forging engine components such as crankshafts, our cylinders provide the high force and accuracy needed for mass production. Built to withstand intense pressures up to 70 MPa, they deliver consistent performance in demanding automotive environments.

press hydraulic cylinder for automotive manufacturing

Press hydraulic cylinders play a key role in plastic molding presses, enabling the compression and shaping of plastic materials for various products. Whether you’re producing automotive interior components or consumer goods like containers, our cylinders offer precise control for high-quality molding. Designed for durability in high-temperature environments, they ensure efficiency in plastic processing tasks.

hydraulic cylinder for press in plastic molding

In rubber processing, press hydraulic cylinders provide the force needed for vulcanizing and compressing rubber materials in specialized presses. From manufacturing tires to producing rubber seals and gaskets, our cylinders are engineered to handle high temperatures and pressures, ensuring uniform compression and long-lasting performance in challenging rubber processing applications.

press hydraulic cylinder for rubber processing

Case Study: How Our Press Hydraulic Cylinders Improved Efficiency in a Metal Stamping Plant

In a metal stamping plant in Germany, a client needed to reduce cycle times while maintaining precision. We supplied our double-acting press hydraulic cylinders with specialized features that transformed their production line.

Technical Specifications:

Double-acting press hydraulic cylinder

70 MPa

Low-friction seals

Metal stamping plant, Germany

Why Choose Our Press Hydraulic Cylinders?

Engineered for performance and built to last – solving your toughest pressing challenges

High Force Output

Delivers up to 10,000 tons of force, ideal for heavy-duty pressing applications in demanding industrial environments.

- Massive pressing power for thick materials

- Consistent force throughout stroke

- Handles peak loads without deformation

Exceptional Durability

Made with high-strength alloy steel and hard chrome plating, resistant to wear and corrosion.

- Premium alloy steel construction

- Hard chrome-plated rods

- Corrosion-resistant coatings

- 3x longer service life than standard cylinders

Precision Control

Advanced sealing systems ensure leak-free operation and accurate force application.

- ±0.5% force accuracy

- Multi-stage sealing systems

- Precision-ground components

- Vibration damping technology

Custom Solutions

Tailored designs to fit various press models and applications.

- Bore sizes from 50mm to 1000mm

Frequently Asked Questions About Press Hydraulic Cylinders

such as metal forming and forging.

These cylinders convert hydraulic energy into powerful linear motion for various manufacturing processes.

- Force capacity requirements (10-10,000 tons)

- Operating pressure (35-70 MPa range)

- Specific application (stamping/forging/etc.)

- Available space constraints

- Required stroke length and speed

- Single-acting cylinders – For simple pressing operations

- Double-acting cylinders – Precise control in both directions

- Tandem cylinders – For high force applications

- Custom engineered solutions – For specialized press requirements

Available in bore sizes from 50mm to 1000mm.