Y-HG1 Cilindro hidráulico metalúrgico Noraml

Como cilindros hidráulicos uno de los fabricantes, los surtidores y los exportadores de productos mecánicos, ofrecemos cilindros hidráulicos y muchos otros productos.

Póngase en contacto con nosotros para más información.

Correo:sales@hydraulic-cylinders.net

Fabricante proveedor exportador de cilindros hidráulicos.

Y-HG1 Cilindro hidráulico metalúrgico Noraml

The Y-HG1 metallurgical hydraulic cylinder is a state-of-the-art hydraulic component specifically designed to meet the demanding requirements of metallurgical applications. With its advanced features, robust construction, and exceptional performance, the Y-HG1 metallurgical hydraulic cylinder offers precise control, durability, and reliability in the rigorous environments of steel mills, foundries, and other metallurgical processes. Whether for heavy-duty lifting, pressing, or positioning, the Y-HG1 cylinder sets new standards in hydraulic technology, making it the ideal choice for the metallurgical industry.

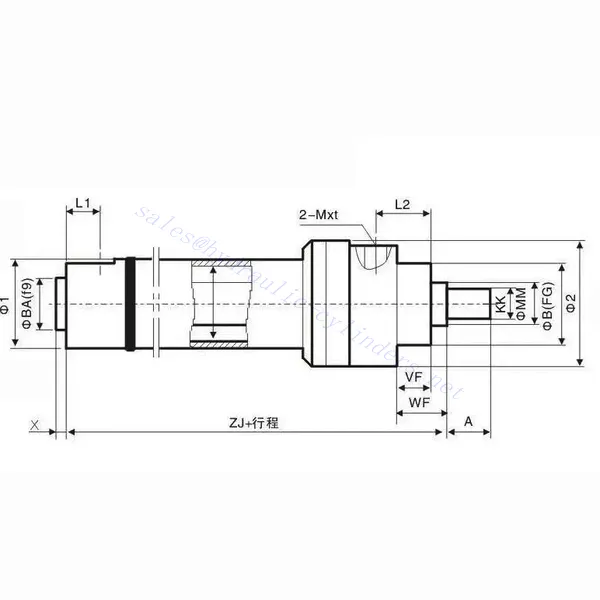

Y-HG1 series of metallurgical equipment hydraulic cylinder for the double acting piston cylinder, cylinder diameter is generally in the range of 40~320mm, the working pressure <=16MPA, the hydraulic oil mechanical system can be used to lose emulsion and other working media, the installation of the flange, earrings, pins, trippers (base) and different types.

High precision CNC honing machine, automatic welding machine, vertical, horizontal machining center, gantry machining center, CNC lathe, and other processing equipment, product quality is stable and guaranteed.

Y-HG1 Noraml Metallurgical Hydraulic Cylinder Parameter:

Y-HG1 Cilindro hidráulico metalúrgico Noraml Usage Method:

- Mounting and Installation:

- Determine the appropriate location for installing Y-HG1 cylinders based on the specific requirements of your metallurgical equipment.

- Make sure the mounting surface is clean, level, and able to support the weight and load of the cylinder.

- Connection to Hydraulic System:

- Connect the Y-HG1 metallurgical hydraulic cylinder using a compatible hydraulic hose or pipe to the hydraulic system.

- Ensure proper alignment and secure connections to prevent leaks and ensure optimal performance.

- System Integration and Calibration:

- Integrate Y-HG1 metallurgical hydraulic cylinders into metallurgical equipment or systems by the manufacturer’s guidelines.

- Calibrate the system to achieve the required operating parameters and ensure precise control of cylinder movement.

- Operating the Cylinder:

- Activate the hydraulic system to apply pressure and initiate the movement of the Y-HG1 cylinder.

- The hydraulic control system precisely controls cylinder extension, contraction and positioning for efficient metallurgical operations.

Y-HG1 Cilindro hidráulico metalúrgico Noraml Características:

- Robust Construction: The Y-HG1 cylinder is built with high-quality materials, ensuring durability and longevity in the demanding metallurgical environment.

- Precise Control: The metallurgical hydraulic cylinder provides superior control and positioning accuracy, allowing operators to achieve exact movement for optimal metallurgical processes.

- High Load Capacity: Y-HG1 metallurgical hydraulic cylinders are designed to handle heavy loads standard in metallurgical applications, providing reliable lifting and pressing capabilities.

- Corrosion Resistance: The cylinder’s corrosion-resistant coating protects it from harsh chemicals and the extreme temperatures often found in metallurgical environments.

- Versatile Mounting Options: Y-HG1 cylinders are available in various mounting options and can be easily integrated into multiple metallurgical equipment and systems.

ow Does A One-Way Hydraulic Cylinder Work?

A one-way, single-acting hydraulic cylinder uses a hydraulic system to generate linear motion in one direction. It consists of a cylinder barrel, piston, piston rod, and hydraulic fluid. Here’s how it works:

- Hydraulic Fluid Supply:

- The hydraulic system supplies pressurized fluid, typically oil, to the cylinder through a hydraulic pump or power source.

- Cylinder Extension:

- When hydraulic fluid is supplied to the cylinder, it enters the cylinder barrel through an inlet port.

- The pressurized fluid pushes against the piston, causing it to move in the desired direction (typically extending the piston rod).

- As the fluid pressure increases, it overcomes the resistance or load on the piston, resulting in the extension of the piston rod.

- Sealing Mechanism:

- The cylinder barrel is sealed to prevent fluid leakage. It typically incorporates seals around the piston and piston rod, such as O-rings or lip seals.

- These seals ensure that the pressurized fluid acts only on one side of the piston, creating a pressure imbalance that drives the piston in the desired direction.

- Return Stroke:

- After the extension stroke, the hydraulic fluid is released or vented from the cylinder.

- The hydraulic system may use gravity, a spring, or an external force to retract the piston and piston rod to their initial positions.

- During the return stroke, the hydraulic fluid flows out of the cylinder through an outlet port.

- Load Support:

- The piston rod of the hydraulic cylinder is often connected to a load or mechanism that requires linear motion or force.

- As the piston extends or retracts, it provides the necessary force to move or support the load.

- Control and Valves:

- To control the extension and retraction of the one-way hydraulic cylinder, the hydraulic system incorporates valves, such as check valves or directional control valves.

- These valves regulate the flow of hydraulic fluid, allowing it to enter and exit the cylinder in the desired direction.

- Application Specifics:

- One-way hydraulic cylinders are commonly used in applications where force or motion is required in only one direction, such as lifting, pushing, or clamping.

- They are often found in hydraulic jacks, hydraulic presses, dump trucks, and various other industrial and mobile equipment.

Capacidad de la fábrica:

(1) Montaje

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Mecanizado

El taller de mecanizado está equipado con un centro de torneado de carril inclinado personalizado, un centro de mecanizado, una máquina de bruñido de alta velocidad, un robot de soldadura y otros equipos relacionados, que pueden procesar tubos cilíndricos con un diámetro interior máximo de 400 mm y una longitud máxima de 6 metros.

(3) Soldadura

(4) Pintura y revestimiento

Con pequeñas y medianas líneas de cilindros automáticos de recubrimiento de pintura a base de agua, para lograr la carga y descarga automática de robots y pulverización automática, la capacidad de diseño de 4000 piezas por turno;

También disponemos de una línea semiautomática de producción de pintura para grandes cilindros accionada por cadena, con una capacidad de diseño de 60 cajas por turno.

(5) Pruebas

Disponemos de instalaciones de inspección y bancos de pruebas de primera clase para garantizar que el rendimiento del cilindro cumple los requisitos.

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding cajas de cambios agrícolas. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and colabore con nosotros!

Visite nuestra fábrica de RV:

Haga un recorrido por nuestra fábrica de RV con lo siguiente

¿Cómo funciona el cilindro hidráulico de una carretilla elevadora?

Cilindro hidráulico Aplicación: