Aerial Work Platform Leveling Cylinder

Como cilindros hidráulicos uno de los fabricantes, los surtidores y los exportadores de productos mecánicos, ofrecemos cilindros hidráulicos y muchos otros productos.

Póngase en contacto con nosotros para más información.

Correo:sales@hydraulic-cylinders.net

Fabricante proveedor exportador de cilindros hidráulicos.

Aerial Work Platform Leveling Cylinder

The aerial work platform leveling cylinder is an essential component designed to enhance stability and safety in aerial work platforms. This specialized hydraulic cylinder plays a vital role in adjusting and maintaining the platform level while operating at elevated heights.

The aerial work platform leveling cylinder is crucial for ensuring stability and safety in elevated work environments. With its robust construction, precise leveling capabilities, smooth operation, and essential safety features, this hydraulic cylinder is vital in maintaining a stable and level platform. By following the recommended usage methods and maintenance practices, operators can maximize the longevity and performance of the aerial work platform leveling cylinder, contributing to enhanced productivity, safety, and confidence in various elevated work applications. Invest in this essential hydraulic component to elevate your aerial work platform’s stability and unlock new levels of efficiency and safety in formal work scenarios.

Aerial Work Platform Leveling Cylinder Key Characteristics:

- Robust Construction:

- The aerial work platform leveling cylinder is built with high-quality materials, ensuring durability and longevity.

- It is designed to withstand heavy loads and the rigors of demanding work environments.

- Precise Leveling:

- This cylinder allows precise and controlled leveling of the aerial work platform.

- It enables operators to adjust the platform’s position to compensate for uneven surfaces, ensuring a stable and secure working environment.

- Smooth Operation:

- The hydraulic system of the aerial work platform leveling cylinder ensures smooth and seamless adjustment of the platform’s level.

- It allows operators to make real-time adjustments, adapt to changing work conditions, and maintain optimal stability.

- Safety Features:

- The leveling cylinder has safety mechanisms that prevent sudden movements or uncontrolled shifts in the platform’s position.

- It enhances operator safety by providing a stable and level platform, reducing the risk of accidents or equipment damage.

Aerial Work Platform Leveling Cylinder Parameter:

| Product Name | Aerial Work Platform Leveling Cylinder |

| Features: | Adjust the angle of the aerial work platform |

| Bore diameter: | 85mm~180mm |

| Rod diameter: | 50mm~100mm Stroke≤300mm |

| Pressure: | 30MPa(Maximum pressure) |

| Leveling Cylinder Applications: | Aerial Work Platform |

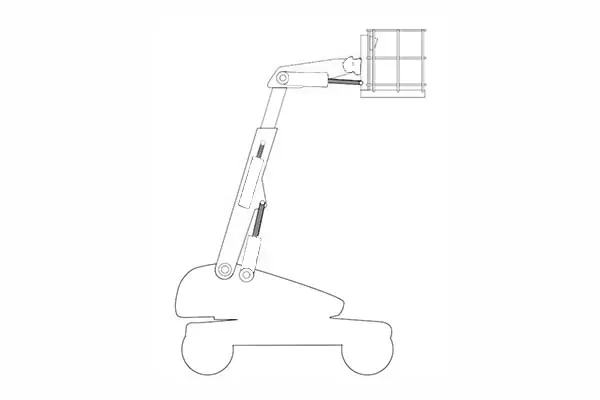

Aerial Work Platform Identification Diagram:

Usage Method Of Aerial Work Platform Leveling Cylinder:

- Installation and Setup:

- Follow the manufacturer’s instructions for proper installation and setup of the Aerial Work Platform Leveling Cylinder.

- Ensure that the cylinder is securely mounted and aligned to ensure optimal performance.

- Hydraulic Connection:

- Connect the leveling cylinder to the hydraulic system of the aerial work platform according to the provided guidelines.

- Ensure that all hydraulic connections are secure and properly sealed to prevent leaks or loss of hydraulic fluid.

- Leveling Operation:

- Engage the control mechanisms on the aerial work platform to adjust the platform’s level.

- Follow the recommended procedures and safety guidelines during the leveling operation.

- Real-Time Adjustments:

- Monitor the platform’s level and make necessary adjustments using the control mechanisms.

- Continuously assess the working surface and adapt the platform’s position to maintain stability and safety.

How To Release Pressure On Hydraulic System?

Releasing pressure from a hydraulic system is essential for maintenance, repairs, or working with hydraulic components. Here are some general steps to safely remove stress from a hydraulic system:

- Identify the Power Source:

- Locate the power source that supplies pressure to the hydraulic system. This is typically a hydraulic pump or an engine-driven power unit.

- Identify the power supply and ensure it is turned off or the engine is shut down to prevent accidental activation.

- Engage Control Levers:

- Move any control levers or switches to their neutral or off positions. This helps prevent unintended movement of hydraulic components and reduces the risk of pressure buildup.

- Relieve Pressure at the Control Valve:

- Locate the control valve or pressure relief valve in the hydraulic system. It is usually marked or labeled for easy identification.

- Slowly turn or adjust the valve to its release or open position. This allows trapped hydraulic fluid to escape and reduces pressure in the system.

- It is essential to release pressure gradually to avoid sudden movements or fluid discharge.

- Monitor Pressure Gauge:

- Some hydraulic systems may have pressure gauges installed. If available, monitor the pressure gauge while releasing pressure.

- As you open the control valve, observe the pressure gauge to ensure the pressure is decreasing steadily.

- Bleed Hydraulic Components:

- After relieving pressure at the control valve, it is advisable to bleed the hydraulic components that may still hold residual pressure.

- Start by loosening or removing any fittings or connections downstream of the control valve.

- Slowly and carefully open the fittings to allow any remaining pressure to escape.

- Use caution as hydraulic fluid may be under pressure and can spray or leak out.

- Verify Pressure Release:

- Double-check that pressure has been effectively released from the system by confirming the pressure gauge reads zero or close to zero.

- Inspect the hydraulic components to ensure no movement or signs of pressure remaining.

Capacidad de la fábrica:

(1) Montaje

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Mecanizado

El taller de mecanizado está equipado con un centro de torneado de carril inclinado personalizado, un centro de mecanizado, una máquina de bruñido de alta velocidad, un robot de soldadura y otros equipos relacionados, que pueden procesar tubos cilíndricos con un diámetro interior máximo de 400 mm y una longitud máxima de 6 metros.

(3) Soldadura

(4) Pintura y revestimiento

Con pequeñas y medianas líneas de cilindros automáticos de recubrimiento de pintura a base de agua, para lograr la carga y descarga automática de robots y pulverización automática, la capacidad de diseño de 4000 piezas por turno;

También disponemos de una línea semiautomática de producción de pintura para grandes cilindros accionada por cadena, con una capacidad de diseño de 60 cajas por turno.

(5) Pruebas

Disponemos de instalaciones de inspección y bancos de pruebas de primera clase para garantizar que el rendimiento del cilindro cumple los requisitos.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding cajas de cambios agrícolas. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and colabore con nosotros!

Visite nuestra fábrica de RV:

Haga un recorrido por nuestra fábrica de RV con lo siguiente

¿Cómo funciona el cilindro hidráulico de una carretilla elevadora?

Cilindro hidráulico Aplicación: