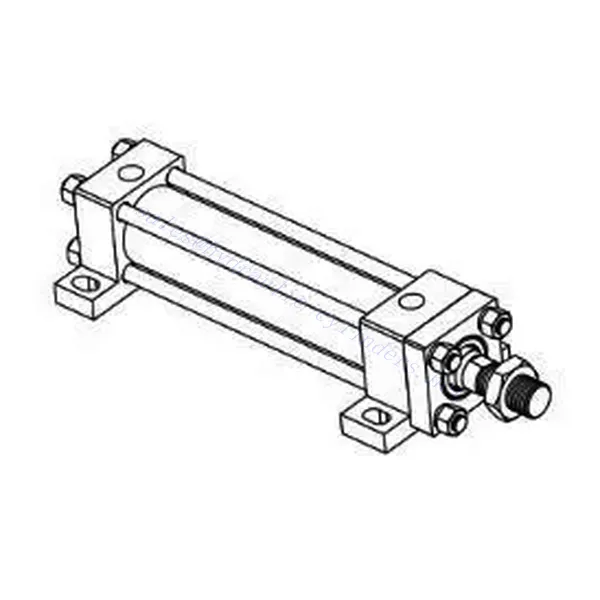

Cilindro hidráulico de biela pesada tipo pie izquierdo y derecho LA

Como cilindros hidráulicos uno de los fabricantes, los surtidores y los exportadores de productos mecánicos, ofrecemos cilindros hidráulicos y muchos otros productos.

Póngase en contacto con nosotros para más información.

Correo:sales@hydraulic-cylinders.net

Fabricante proveedor exportador de cilindros hidráulicos.

Cilindro hidráulico de biela pesada tipo pie izquierdo y derecho LA

The LA left and right foot heavy rod hydraulic cylinder is a cutting-edge hydraulic element designed to meet the needs of various industrial applications. With its rugged construction, superior force output, and unique left and right foot design, this hydraulic cylinder offers exceptional power, precision, and versatility. Whether heavy lifting, pushing, or pulling, LA left and right foot type heavy-duty rod hydraulic cylinders provide reliable performance to optimize industrial operations.

Essential Characteristics Of Heavy Rod Hydraulic Cylinder:

Robust Construction: Using high-quality materials such as solid steel or alloys, LA left and right foot type heavy rod hydraulic cylinders ensure durability and longevity. Its rugged construction allows it to handle heavy loads, high pressures, and challenging environmental conditions, making it suitable for demanding industrial tasks.

High Force Output: This hydraulic cylinder boasts impressive force output, making it ideal for applications requiring substantial power. Its large piston diameter and high-pressure capabilities provide exceptional strength to handle heavy-duty tasks easily.

Left and Right Foot Design: The LA left and right foot heavy rod hydraulic cylinder has a unique left and right foot design that allows for various mounting options. This design is easy to install and integrate into multiple hydraulic systems and equipment configurations, providing flexibility and adaptability.

Precise Control: Equipped with precision machined components and high-quality seals, this hydraulic cylinder ensures accurate and reliable operation. It can precisely control the movement and positioning of loads for efficient and appropriate processing.

LA Left And Right Foot Type Heavy Rod Hydraulic Cylinder Parameter:

Cilindro hidráulico de biela pesada tipo pie izquierdo y derecho LA Usage Method:

Mounting: Start by safely installing the LA left and right foot weight rod hydraulic cylinders using appropriate brackets or fixtures. Ensure proper alignment and stability during installation to prevent cylinder misalignment or stress.

Hydraulic System Integration: Connect hydraulic lines to cylinder ports per manufacturer’s instructions and guidelines. Integrate the cylinder into the hydraulic system by clicking on the appropriate pump or power unit. Ensure cylinder specifications and operating requirements are met.

Control and Operation: The control valve in the hydraulic system regulates the flow of hydraulic oil into and out of the cylinder. Adjust the control Settings according to the desired linear motion and force output. Test the movement of the cylinder to verify its function and responsiveness.

Cilindro hidráulico de biela pesada tipo pie izquierdo y derecho LA Maintenance:

Regular maintenance ensures optimal performance and longevity of the LA left and right foot type heavy rod hydraulic cylinder. Follow these maintenance guidelines:

Regular Inspection: Perform routine inspections to identify signs of wear, damage, or leaks. Check for abnormalities in cylinder blocks, piston rods, seals, and other components. Resolve any issues promptly to prevent further injury or operational inefficiencies.

Lubrication: Apply the recommended lubricant to the moving parts of the cylinder, including tie rods and seals. Regular lubrication minimizes friction, reduces wear, and ensures smooth operation. Use the appropriate lubricant type according to the manufacturer’s lubrication interval guidelines.

Seal Replacement: If seals are found to be deteriorating or leaking, replace seals with genuine parts approved by the manufacturer. Damaged or worn seals can compromise the cylinder’s performance and lead to hydraulic oil leakage.

Cleaning: Clean cylinders by removing dirt, debris, and other contaminants. Before reassembling, use a non-abrasive cleaner and make sure all parts are arid. Regular cleaning promotes optimal performance and prevents premature wear or damage.

How To Control Hydraulic Cylinder Speed?

Controlling the speed of a hydraulic cylinder is essential to ensure safe and efficient operation in various applications. There are several methods to control the speed of a hydraulic cylinder, including the following:

- Flow Control Valves: Flow control valves are commonly used to regulate the speed of hydraulic cylinders. These valves control the flow rate of hydraulic fluid entering or exiting the cylinder, thereby controlling the cylinder’s speed. There are two types of flow control valves:a. Throttle Valves: Throttle valves restrict the flow of hydraulic fluid by creating a narrow passage. They regulate the speed by controlling fluid flow through the valve. Throttle valves are often adjustable, allowing for precise speed control.b. Needle Valves: Needle valves have a tapered needle-like plunger that can be adjusted to restrict or allow fluid flow. By adjusting the position of the needle, the flow rate and, consequently, the cylinder speed can be controlled.

- Proportional Control Valves: Proportional control valves offer more precise control over the speed of hydraulic cylinders. These valves modulate the flow of hydraulic fluid based on electrical or electronic signals, allowing for fine adjustment of the cylinder’s speed. Proportional control valves are often used in applications where precise speed control is critical, such as in automation systems.

- Variable Displacement Pumps: In some hydraulic systems, variable displacement pumps control the speed of hydraulic cylinders. These pumps adjust the volume of fluid delivered to the cylinder, thereby regulating the cylinder speed. By changing the pump’s displacement or stroke volume, the speed of the cylinder can be adjusted accordingly.

- Load-Sensing Systems: Load-sensing systems are advanced hydraulic systems that adjust the pump’s output to match the load requirements. These systems monitor the pressure in the hydraulic circuit and adjust the pump’s displacement accordingly. By maintaining a constant pressure, load-sensing systems can regulate the cylinder speed even under varying load conditions.

- Accumulators: Hydraulic accumulators can be used to control the speed of hydraulic cylinders in specific applications. An accumulator stores hydraulic fluid under pressure, which can be released to supplement the flow from the pump. By controlling fluid release from the accumulator, the speed of the cylinder can be adjusted.

- Gearboxes or Transmission Systems: In some cases, mechanical gearboxes or transmission systems can be employed to indirectly control the speed of hydraulic cylinders. By adjusting the gear ratio or transmission settings, the rotational speed of the input shaft can be translated into the desired speed for the hydraulic cylinder.

Capacidad de la fábrica:

(1) Montaje

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Mecanizado

El taller de mecanizado está equipado con un centro de torneado de carril inclinado personalizado, un centro de mecanizado, una máquina de bruñido de alta velocidad, un robot de soldadura y otros equipos relacionados, que pueden procesar tubos cilíndricos con un diámetro interior máximo de 400 mm y una longitud máxima de 6 metros.

(3) Soldadura

(4) Pintura y revestimiento

Con pequeñas y medianas líneas de cilindros automáticos de recubrimiento de pintura a base de agua, para lograr la carga y descarga automática de robots y pulverización automática, la capacidad de diseño de 4000 piezas por turno;

También disponemos de una línea semiautomática de producción de pintura para grandes cilindros accionada por cadena, con una capacidad de diseño de 60 cajas por turno.

(5) Pruebas

Disponemos de instalaciones de inspección y bancos de pruebas de primera clase para garantizar que el rendimiento del cilindro cumple los requisitos.

We are one of the best heavy rod hydraulic cylinder manufacturers. We can offer wide heavy rod hydraulic cylinder stock. We also provide corresponding cajas de cambios agrícolas. Hemos exportado nuestros productos a clientes de todo el mundo y nos hemos ganado una buena reputación gracias a la calidad superior de nuestros productos y a nuestro servicio posventa. Invitamos cordialmente a los clientes nacionales y extranjeros a ponerse en contacto con nosotros para negociar negocios, intercambiar información y... colabore con nosotros!

Visite nuestra fábrica de RV:

Haga un recorrido por nuestra fábrica de RV con lo siguiente

¿Cómo funciona el cilindro hidráulico de una carretilla elevadora?

Cilindro hidráulico Aplicación: