HCYY11112013 Locking Cylinder For Environmental Protection

Som en af producenterne, leverandørerne og eksportørerne af mekaniske produkter tilbyder vi hydrauliske cylindre og mange andre produkter.

Kontakt os for yderligere oplysninger.

Mail:sales@hydraulic-cylinders.net

Producent, leverandør og eksportør af hydrauliske cylindre.

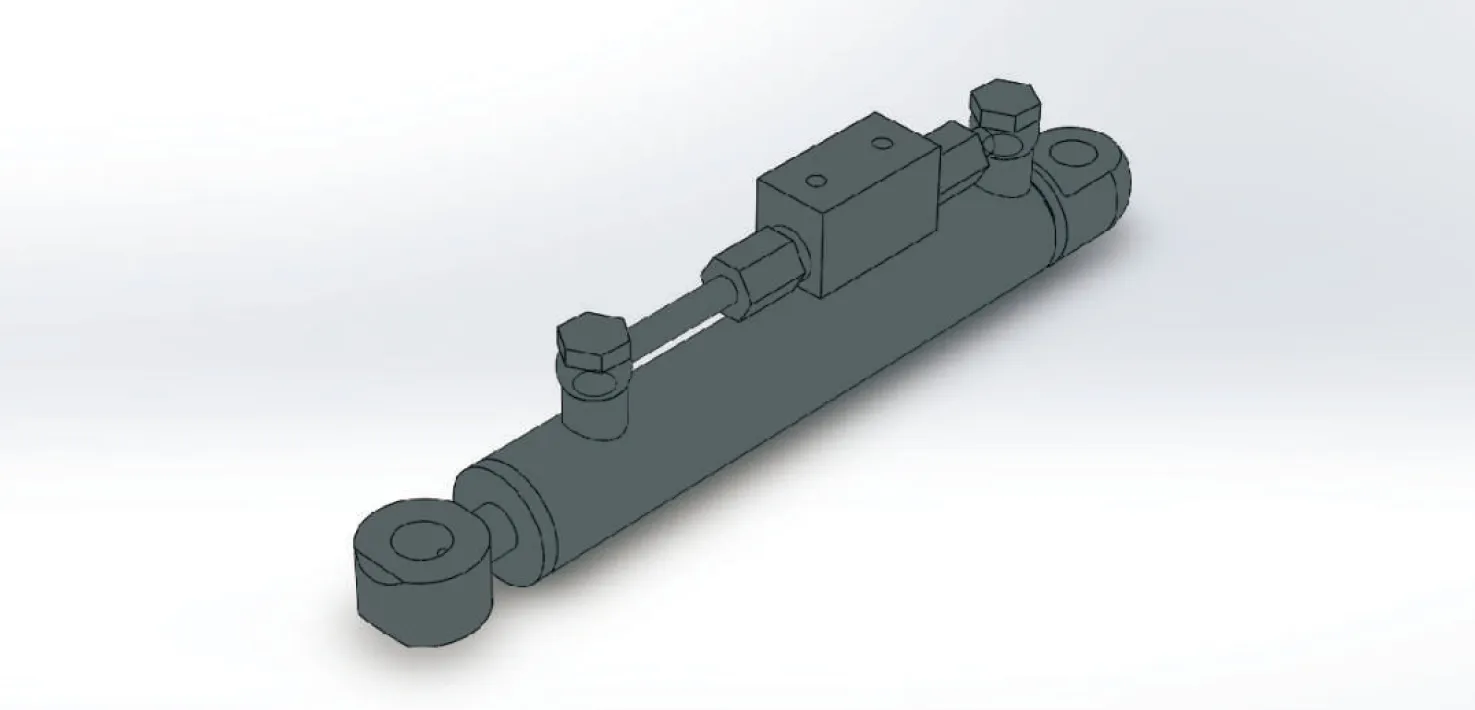

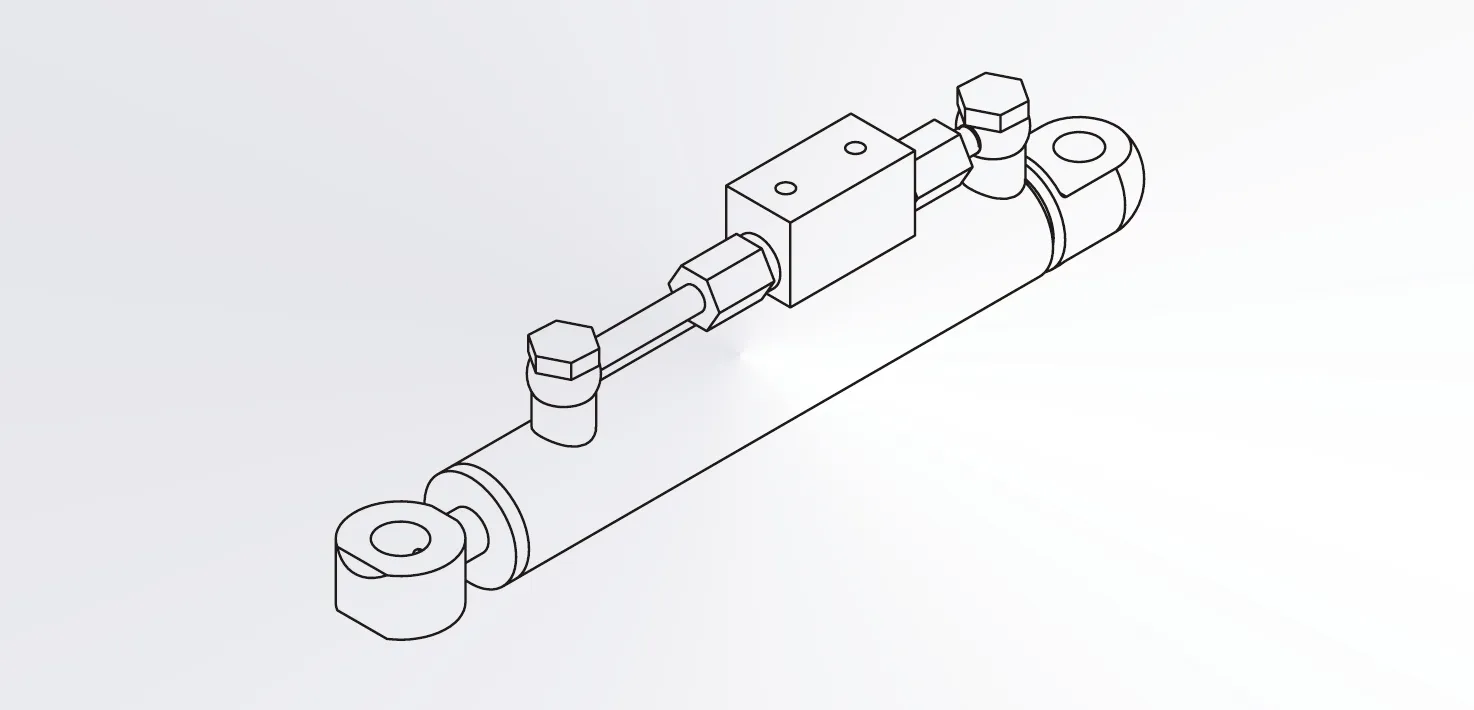

HCYY11112013 Locking Cylinder For Environmental Protection

The HCYY11112013 Locking Cylinder represents a revolutionary advancement in safety and efficiency, particularly for industries dedicated to environmental protection. This innovative component guarantees secure machinery operation while significantly reducing the risk of environmental hazards.

What sets the HCYY11112013 Locking Cylinder apart is its remarkable reliability and efficiency. Its robust design and enhanced safety features make it an indispensable asset in today’s industrial landscape. By adhering to proper usage and maintenance practices, users can maximize the longevity and performance of this essential product. This promotes safer operations and contributes to a more sustainable future. Embrace the power of the HCYY11112013 Locking Cylinder and elevate your commitment to safety and environmental stewardship!

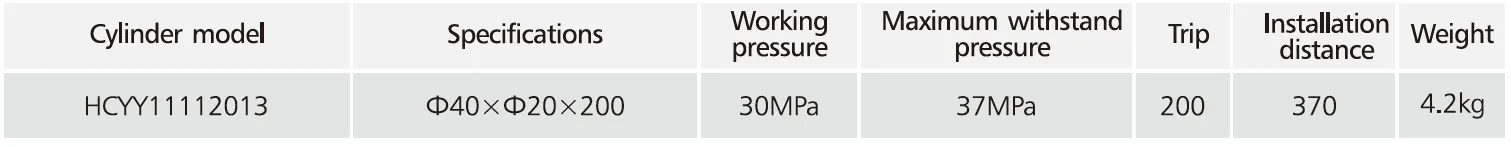

HCYY11112013 Locking Cylinder For Environmental Protection Parameter:

Cylinder Series For Environmental Protection:

Key Features of the HCYY11112013 Locking Cylinder:

What Makes The Hcyy11112013 Locking Cylinder Environmentally Friendly?

The HCYY11112013 Locking Cylinder stands out in the realm of environmentally friendly technologies, and here’s why it deserves your attention:

1. Sustainable Materials

Crafted from high-quality, recyclable materials, the HCYY11112013 not only meets safety standards but also champions sustainability. By choosing materials that can be repurposed, it helps reduce waste and supports a circular economy—a crucial factor in today’s eco-conscious world.

2. Low Emission Design

This locking cylinder is engineered with emissions in mind. Its innovative design minimizes the release of harmful substances during operation, contributing to cleaner air and a healthier environment. This aspect is particularly vital in applications near sensitive ecological areas, ensuring minimal disruption.

3. Energy Efficiency

In an era where energy conservation is paramount, the HCYY11112013 excels. It operates with low energy consumption, which not only cuts down on operational costs but also plays a significant role in reducing the carbon footprint. This efficiency makes it an ideal choice for organizations aiming to meet their sustainability goals.

4. Leak Prevention Technology

One of the standout features of this cylinder is its advanced sealing mechanisms. These ensure that there are no leaks of potentially harmful substances, safeguarding both the environment and the communities that depend on it. This protective measure is essential in industries where chemical handling is prevalent.

5. Longevity and Durability

Built to last, the HCYY11112013 Locking Cylinder boasts a long lifecycle, which means fewer replacements and reduced resource consumption over time. This durability not only saves money in the long run but also lessens the environmental impact associated with manufacturing and disposal.

In summary, the HCYY11112013 Locking Cylinder is more than just a mechanical component; it is a commitment to environmental stewardship. By integrating sustainability into its design and functionality, it paves the way for safer and greener industrial practices. Whether you’re in manufacturing, construction, or any field that values environmental responsibility, this locking cylinder is a smart choice that aligns with your goals for a sustainable future.

Forklift Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: