HRO Type Round Hydraulic Cylinder

Som en af producenterne, leverandørerne og eksportørerne af mekaniske produkter tilbyder vi hydrauliske cylindre og mange andre produkter.

Kontakt os for yderligere oplysninger.

Mail:sales@hydraulic-cylinders.net

Producent, leverandør og eksportør af hydrauliske cylindre.

HRO Type Round Hydraulic Cylinder

The HRO Round Hydraulic Cylinder is an advanced hydraulic component designed for reliable and efficient power transmission across various industrial applications. With its innovative design, superior performance, and rugged construction, this hydraulic cylinder ensures precise control, exceptional durability, and versatile operation. Whether utilized in manufacturing, building, or material handling, HRO Round Hydraulic Cylinders are engineered to optimize hydraulic functions and enhance overall productivity.

Our company boasts advanced processing equipment, including vertical and horizontal machining centers, gantry machining centers, and high-precision CNC grinding machines. We specialize in producing a wide range of hydraulic products, including angle cylinders, heavy-rod hydraulic cylinders, pull-rod cylinders, engineering cylinders, metallurgical cylinders, non-standard cylinders, custom cylinders, hydraulic systems, hydraulic power stations, hydraulic valves, and hydraulic machinery. Our products are applicable in various industries, offering cost-effective solutions with a complete lineup.

The HRO series round cylinders are safe, stable, and easy to maintain. They feature attractive designs and high quality, making them suitable for all presses. We invite national manufacturers to discuss potential cooperation.

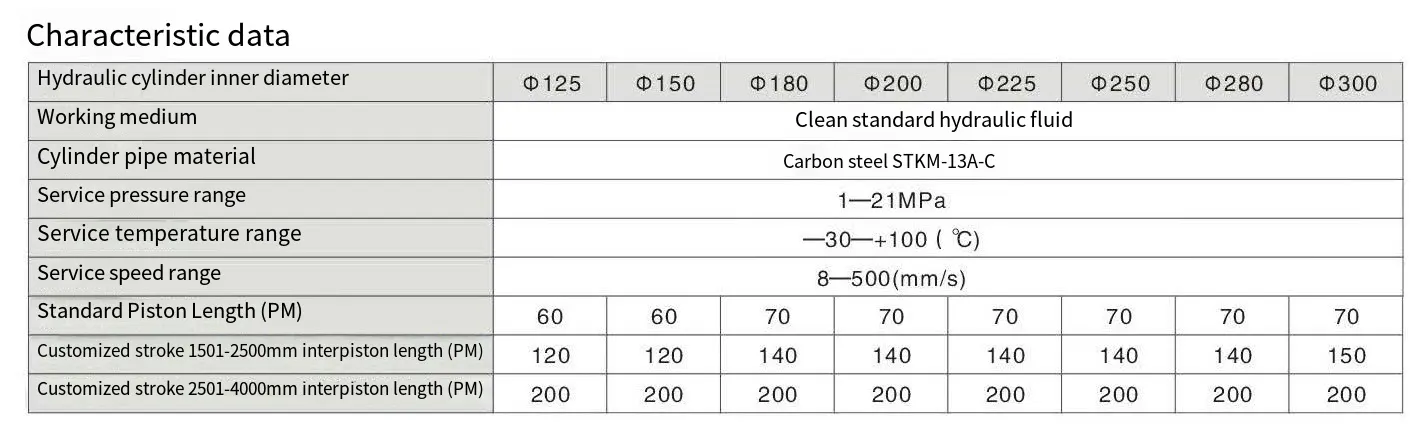

HROA Type Circular Hydraulic Cylinder Characteristic Data:

Hro Circular Cylinder Features:

1) The circular cylinder has the advantages of safety and stability, large output, and easy maintenance;

2) Maximum cylinder diameter 350MM;

3) Travel can be 5 meters;

4) Use pressure: 14~21Mpa

HROA Type Circular Hydraulic Cylinder Structure Diagram:

HRO Type Round Hydraulic Cylinder Parameter:

(1)HROD Biaxial Type With Adjustable Cap Round Hydraulic Cylinder

(2)HROB Type Standard B Type Round Hydraulic Cylinder

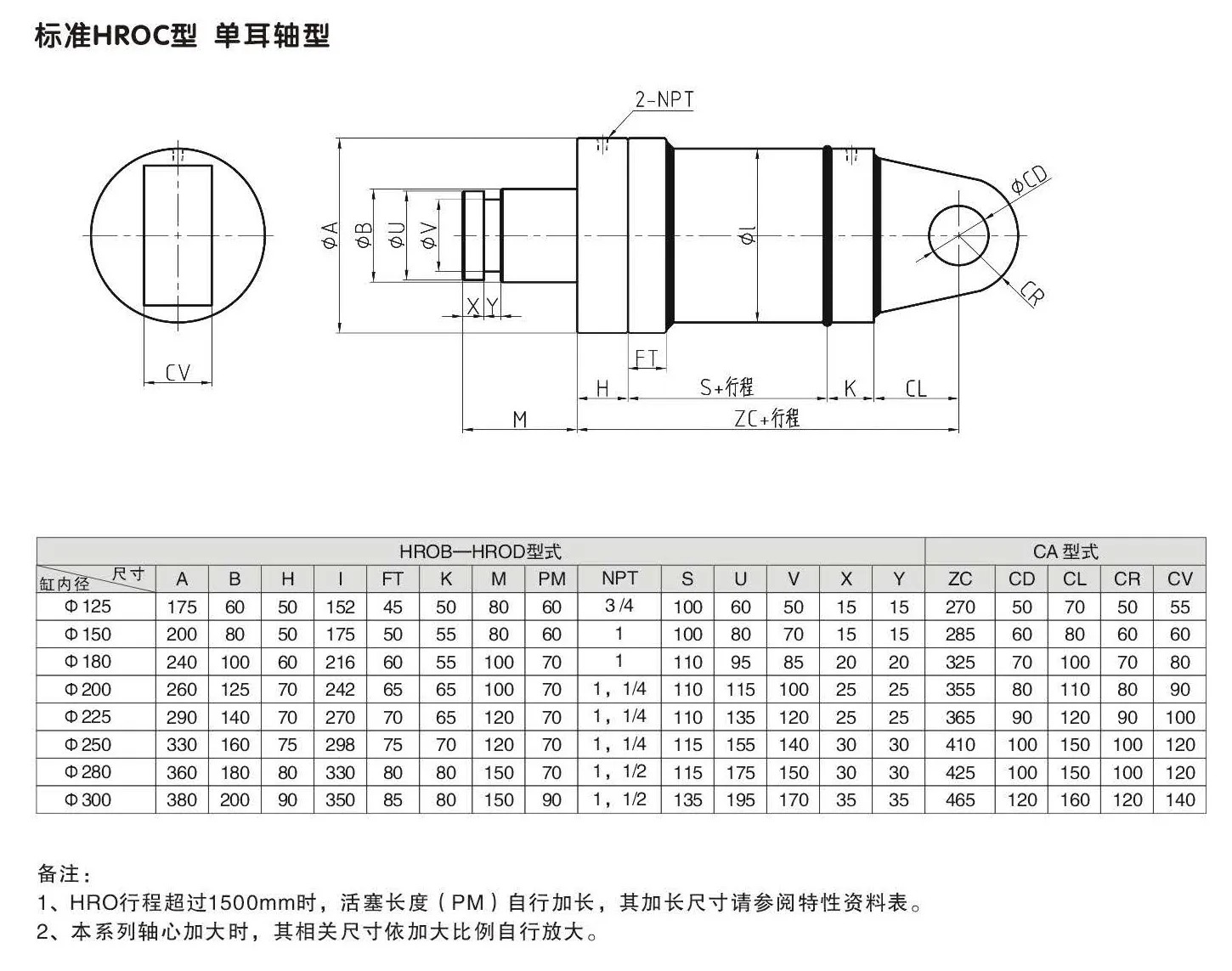

(3)HROC Single Trunnion Type Round Hydraulic Cylinder

(4)HROE Rear Flange Type Round Hydraulic Cylinder

HRO Type Round Hydraulic Cylinder External Tooth Type Specification Sheet:

(1)HROB Type Standard B Type Circular Hydraulic Cylinder

(2)HROC Single Trunnion Type Round Hydraulic Cylinder

(3)HROE Rear Flange Type Round Hydraulic Cylinder

Large Hydraulic Cylinder Model Description:

HROA-125/60*100+Y+DM

HROA — Type: HROA= Oil port in front of flange HROB= Oil port in back of flange HROC=CA type HROD= biaxial type HROE= flange in back

125– Cylinder diameter: Φ125, Φ150, Φ180, Φ200, Φ225, Φ250, Φ280, Φ300

60– Axis ROD standard: Φ60, Φ80, Φ100, Φ120, Φ140, Φ160, Φ180, Φ200

Axis ROD maximum: Φ80, Φ100, Φ120, Φ140, Φ160, Φ200, Φ220, Φ250

100 — Travel: Standard maximum travel 4 meters

Y– Cylinder block fixed type: YP=Y with PIN I=I type joint TW= half moon sleeve + welding sleeve A= adjustable nuts

DM — No mark =DM core wheel type

What Applications Are Best Suited For Round Hydraulic Cylinders?

Industrial Machinery

Presses: Round hydraulic cylinders are crucial in metal forming processes, providing the necessary force to shape materials efficiently.

Lifts: They are used in scissors and platform lifts to safely raise and lower heavy equipment or personnel.

Construction Equipment

Excavators: Round cylinders power the boom and arm movements, allowing for effective digging and lifting.

Cranes: They are essential for controlling the movement of crane booms or jibs, facilitating heavy lifting and placement.

Automotive Industry

Hydraulic Lifts: Used in service stations for lifting vehicles for maintenance and repairs.

Assembly Line Equipment: They assist in moving components and parts during the manufacturing process.

Agricultural Equipment

Tractors: Round hydraulic cylinders are used in implements like loaders and tillers, providing the necessary force for different agricultural tasks.

Harvesters: They facilitate the operation of cutting and collecting mechanisms, improving efficiency during harvest.

Material Handling

Forklifts: Round hydraulic cylinders are integral for lifting and lowering loads, allowing for efficient warehouse operations.

Pallet Jacks: They enable the easy movement of heavy pallets, making them essential in logistics.

Mining

Drilling Rigs: These cylinders provide the force needed to operate drilling equipment, ensuring precision and power in tough environments.

Material Transport: Used in conveyors and other machinery to handle heavy materials safely.

Marine Applications

Deck Machinery: Round hydraulic cylinders control winches, cranes, and other ship equipment, facilitating loading and unloading operations.

Steering Systems: They are used in hydraulic steering systems to precisely control vessels.

Aerospace

Landing Gear: Round hydraulic cylinders are critical in retracting and extending landing gear, ensuring reliable aircraft operation.

Control Surfaces: They assist in the movement of flaps and ailerons, enhancing aircraft maneuverability.

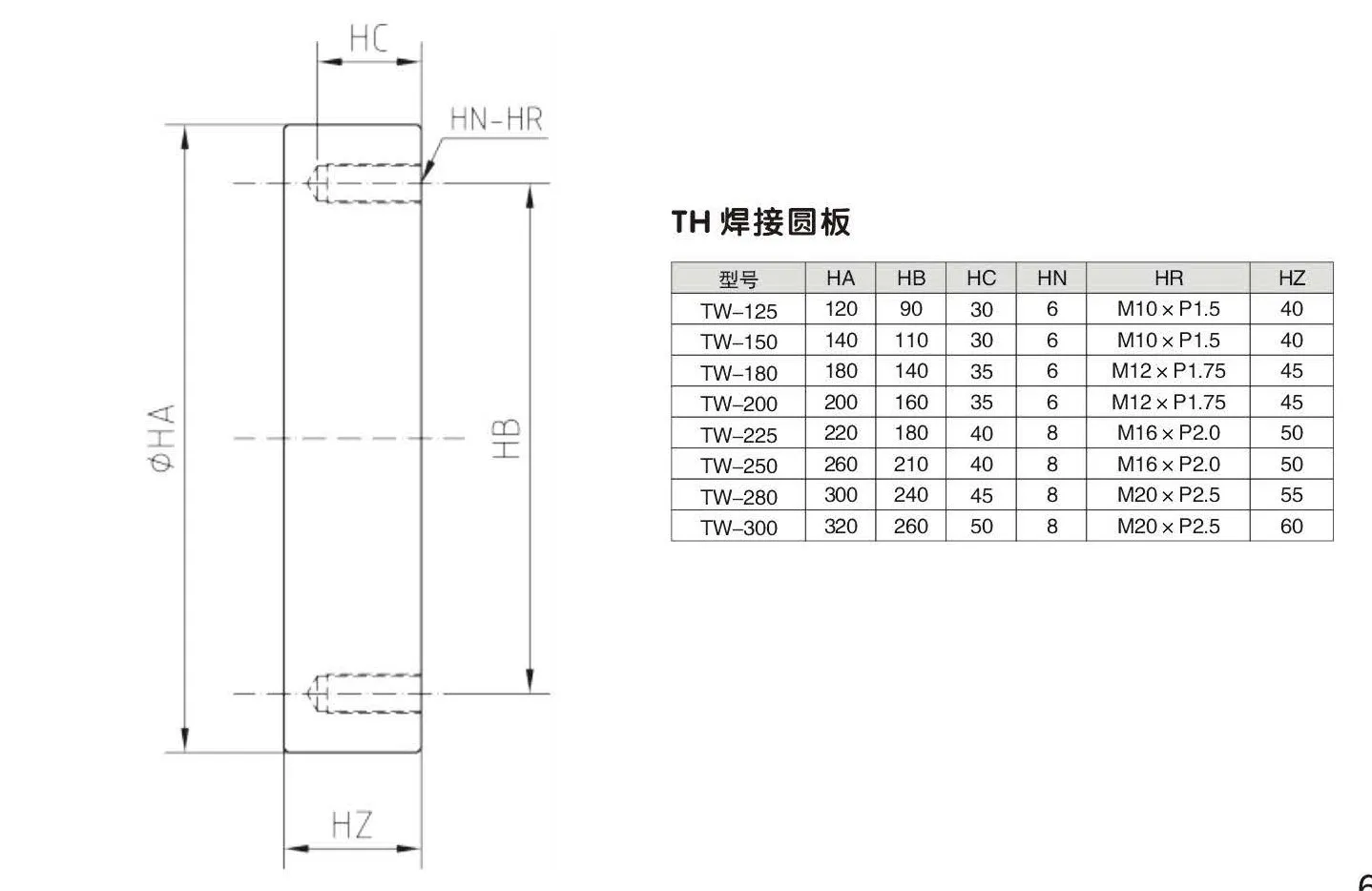

Large Round Hydraulic Cylinder Shaft Fittings Size Diagram:

(1)Tw Half Moon Sleeve

(2)Welded Round Plate

How To Remove Hydraulic Cylinder From Chair?

To remove a hydraulic cylinder from a chair, follow these steps:

- Prepare the Workspace:

- Clear the area around the chair to create a safe and unobstructed workspace.

- Place a protective covering or cloth on the floor to prevent damage to the chair or surrounding surfaces.

- Lower the Chair:

- Use the chair’s adjustment lever or control mechanism to lower it to its lowest position.

- This step ensures that the cylinder is fully compressed, making removing it easier.

- Locate the Cylinder:

- Identify the hydraulic cylinder on the chair. It is typically located near the chair’s base and connects to the seat or the chair’s mechanism.

- Remove the Chair Seat:

- If the chair seat is detachable, locate the mounting screws or bolts that secure it to the cylinder or chair base.

- Use the appropriate tool, such as a screwdriver or wrench, to remove the screws or bolts.

- Lift the seat off the chair, exposing the hydraulic cylinder.

- Support the Chair:

- Since the chair will be unstable without the seat, provide support to prevent it from tipping over.

- Use a sturdy object, such as a box or a wooden block, to prop up the chair’s remaining structure.

- Disconnect the Cylinder:

- Examine the connection points between the hydraulic cylinder and the chair mechanism or base.

- Depending on the chair design, you may find mounting brackets, clips, or screws securing the cylinder.

- Remove any fasteners holding the cylinder in place using the appropriate tools.

- Once the fasteners are removed, gently pull or wiggle the cylinder to detach it from the chair.

- Replace or Dispose of the Cylinder:

- If you are replacing the hydraulic cylinder, ensure you have a compatible replacement that matches the specifications of the old cylinder.

- If necessary, consult the chair manufacturer or a professional for assistance in obtaining the correct replacement cylinder.

- If you are disposing of the cylinder, follow your local regulations and guidelines for proper disposal.

- Reassemble the Chair:

- If you removed the chair seat, reattach it by aligning the screw holes and securing them with the appropriate screws or bolts.

- Make sure the seat is firmly attached and stable before using the chair again.

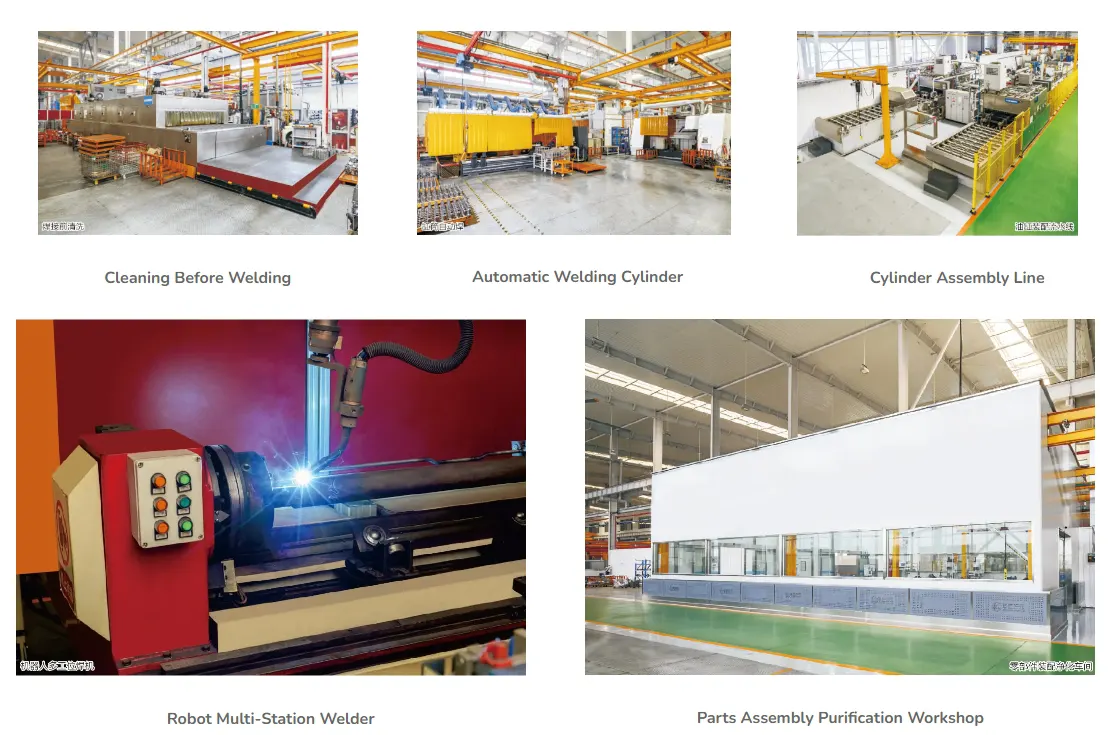

Capability & Capacity Of Factory:

(1) Assembly

Our facility boasts a top-tier independent research and development assembly platform dedicated to hydraulic cylinder production. We operate four semi-automatic lifting cylinder assembly lines and one fully automatic tilt cylinder assembly line, with an impressive annual production capacity of 1 million cylinders.

In our specialized cylinder workshop, we utilize a semi-automatic cleaning assembly system designed for various specifications, capable of producing 200,000 cylinders annually. Our workshop is equipped with advanced CNC machining equipment, a machining center, high-precision cylinder processing tools, robot welding machines, automatic cleaning systems, and an automated cylinder assembly line. Additionally, we have a fully automated painting production line.

With over 300 pieces of critical equipment, our optimal resource allocation ensures that we meet the strict accuracy and quality standards required by our clients. This commitment to efficiency and precision positions us as a leader in the hydraulic cylinder industry.

(2) Machining

Our machining shop features state-of-the-art equipment, including a customized inclined rail turning center, a precision machining center, a high-speed honing machine, and advanced welding robots. This sophisticated setup enables us to efficiently process cylinder tubes with a maximum inner diameter of 400mm and a length of up to 6 meters.

With our cutting-edge technology, we ensure high-quality machining that meets the diverse needs of hydraulic cylinder production.

(3) Welding

(4) Painting & Coating

Our facility features advanced automatic water-based paint coating lines specifically designed for small and medium-sized cylinders. These lines utilize robotic technology for efficient loading, unloading, and spraying, achieving a remarkable production capacity of 4,000 pieces per shift.

In addition, we operate a semi-automatic paint production line for large cylinders, powered by a robust power chain, with a designed capacity of 60 cases per shift. This combination of automation and efficiency ensures high-quality finishes for all our hydraulic cylinders.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are a renowned manufacturer of hydrauliske cylindre, recognized as one of the best in the industry. Our extensive product line includes a wide range of hydraulic cylinders tailored to meet various applications. In addition to hydraulic cylinders, we also provide high-quality agricultural gearboxes, ensuring our customers have access to comprehensive solutions for their machinery needs.

With a commitment to excellence, we have successfully exported our products to clients worldwide, earning a strong reputation for superior product quality and exceptional after-sales service. Our dedication to customer satisfaction has positioned us as a trusted partner in both domestic and international markets.

Why Choose Us?

Professional Expertise: Our team comprises industry professionals with extensive knowledge and experience in hydraulic systems, ensuring that we deliver top-notch products and services.

International Certifications: We adhere to strict quality standards and hold various international certifications, demonstrating our commitment to delivering reliable and safe hydraulic solutions.

Custom Solutions: We understand that each customer’s needs are unique. That’s why we offer customized hydraulic cylinders and gearboxes tailored to meet specific requirements.

Advanced Production Equipment: Our state-of-the-art manufacturing facilities utilize the latest technology and equipment, enabling us to produce high-quality products efficiently.

Comprehensive After-Sales Support: Our commitment to our customers extends beyond the sale. We provide ongoing support and maintenance services to ensure optimal performance of our products.

We invite customers from around the globe to reach out to us for business negotiations, information exchange, and collaboration opportunities. Together, we can achieve greater success in the hydraulic industry!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: