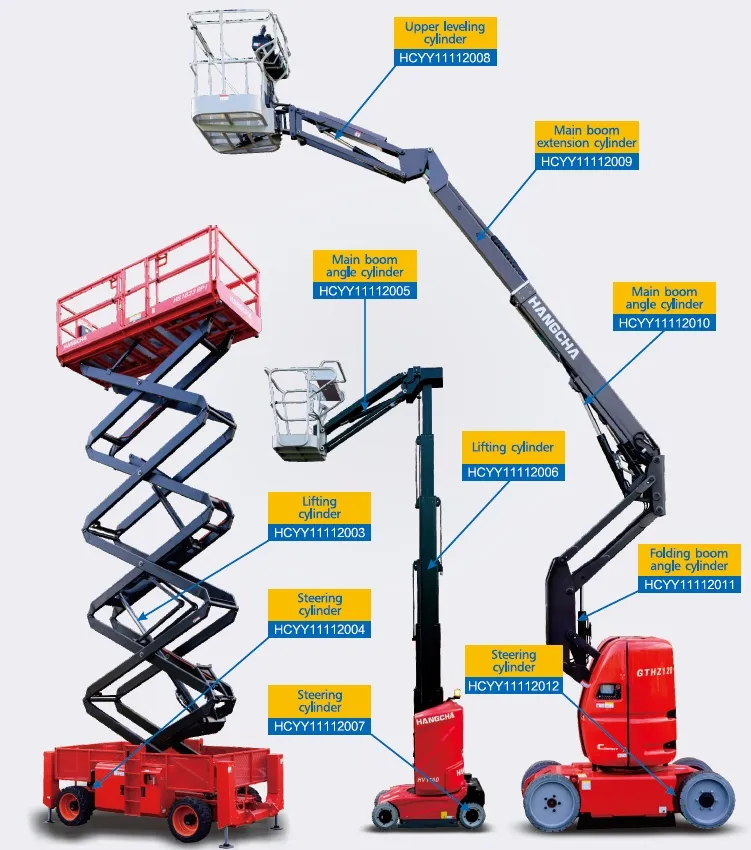

HCYY11112011 Folding Boom Angle Cylinder For Aerial Work Vehicles

Jako jeden z výrobců, dodavatelů a vývozců hydraulických válců nabízíme hydraulické válce a mnoho dalších výrobků.

Kontaktujte nás, prosím, pro podrobnosti.

Mail:sales@hydraulic-cylinders.net

Výrobce, dodavatel a vývozce hydraulických válců.

HCYY11112011 Folding Boom Angle Cylinder For Aerial Work Vehicles

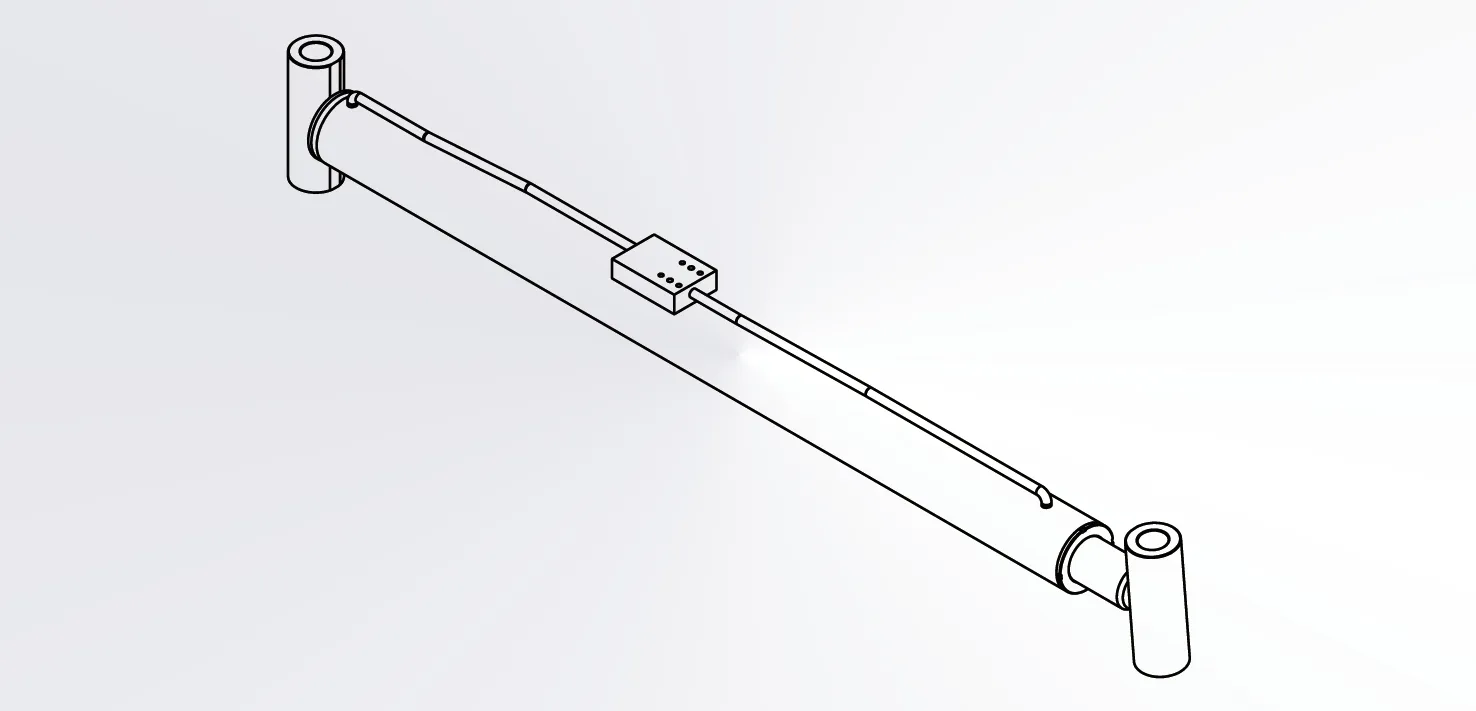

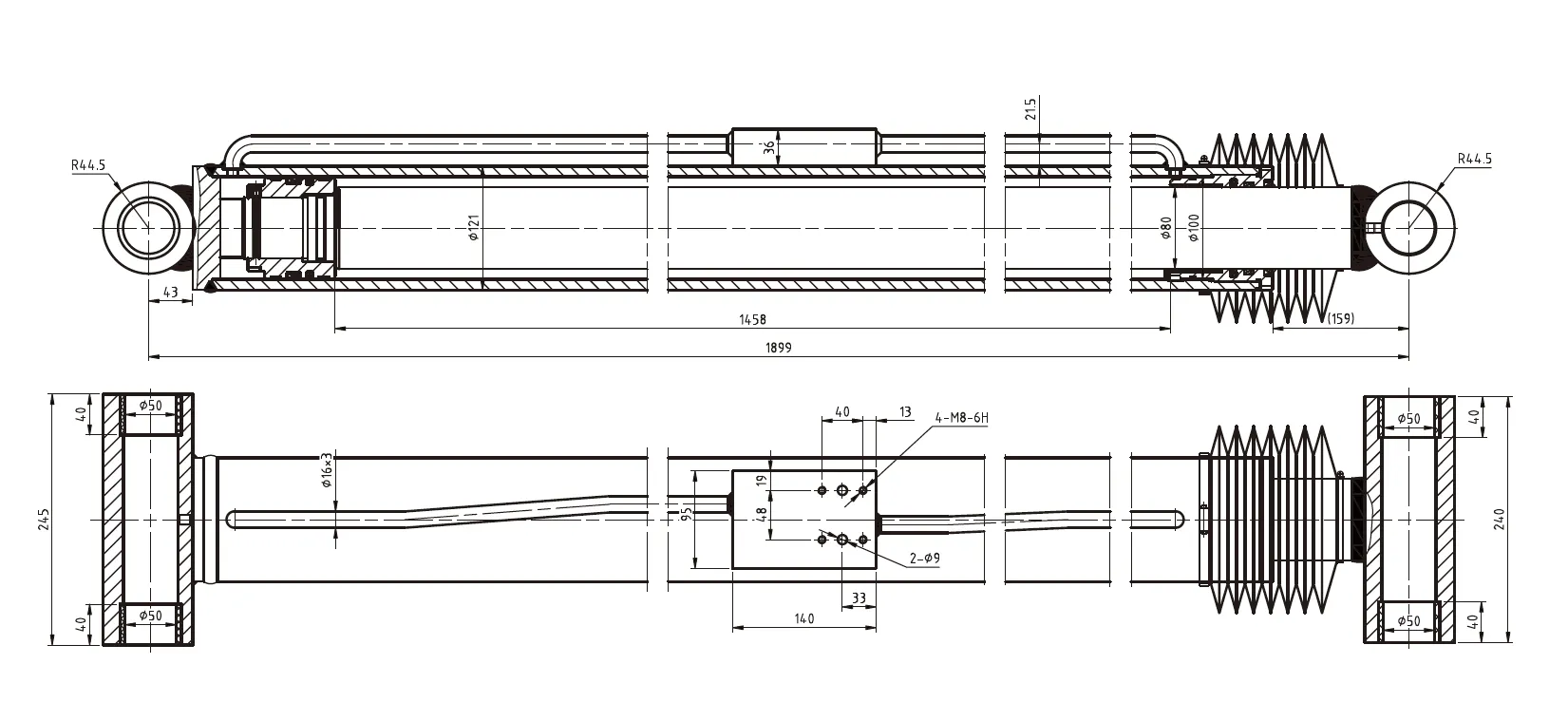

The HCYY11112011 Folding Boom Angle Cylinder is an essential component for aerial work vehicles, engineered to enhance both operational efficiency and safety. This cylinder allows for precise control over the boom’s angle, enabling versatile adjustments for a wide range of aerial tasks. Its robust construction and advanced engineering ensure reliability, making it a crucial part of any aerial work platform.

This folding boom angle cylinder stands out for its durability, precision, and user-friendly design. Whether you’re engaged in maintenance, construction, or other aerial operations, the HCYY11112011 significantly boosts your operational capabilities.

To maximize its performance and longevity, regular maintenance is key. By adhering to proper usage guidelines and conducting routine checks, you can keep the cylinder in optimal condition. This commitment not only extends the lifespan of the cylinder but also protects your investment.

Integrate the HCYY11112011 into your aerial work operations and witness a remarkable improvement in productivity and safety. Elevate your efficiency and experience the reliability that this premium component brings to your projects.

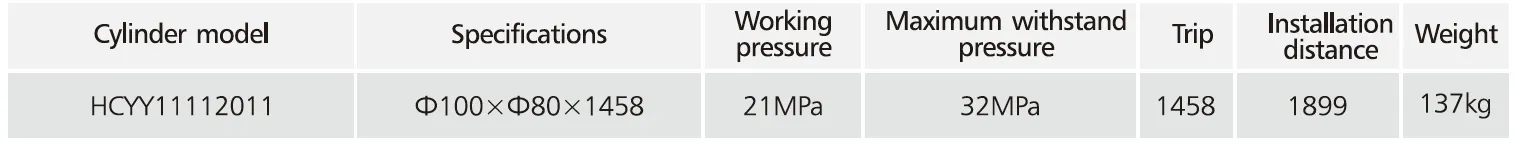

HCYY11112011 Folding Boom Angle Cylinder For Aerial Work Vehicles Parameter:

Cylinder Series For Aerial Work Vehicles:

Key Features of HCYY11112011 Folding Boom Angle Cylinder For Aerial Work Vehicles:

1. Robust Construction

Crafted from premium-grade materials, the HCYY11112011 is designed to endure the toughest conditions. Its heavy-duty construction ensures that it can handle extreme temperatures, abrasive materials, and heavy loads without compromising performance. This durability minimizes the need for frequent replacements, making it a cost-effective choice for businesses.

2. Enhanced Precision Control

The HCYY11112011 provides seamless and precise angle adjustments, enabling operators to position the boom exactly where needed. This feature enhances accuracy during critical aerial tasks, reducing the risk of errors and increasing overall efficiency. Whether maneuvering in tight spaces or adjusting for varying heights, operators can rely on its smooth functionality.

3. Space-Saving Compact Design

The innovative folding mechanism of the HCYY11112011 allows for effortless storage and transportation. When not in use, the cylinder can be neatly folded, taking up minimal space in your vehicle or storage area. This compact design makes it particularly advantageous for mobile operations, where space is often a premium.

4. Impressive Load-Bearing Capacity

Engineered to support substantial weights, the HCYY11112011 is ideal for heavy-duty applications. Its high load capacity enhances reliability, ensuring that it can perform under pressure without failure. This strength is crucial for tasks that require lifting heavy equipment or materials, providing peace of mind to operators.

5. Superior Corrosion Resistance

The HCYY11112011 features advanced coatings that protect against rust and corrosion, extending its operational lifespan. These specialized treatments safeguard the cylinder from harsh weather elements, including rain, snow, and UV exposure. By minimizing wear and tear, this corrosion resistance significantly reduces maintenance costs over time.

6. Easy Installation and Compatibility

Designed for versatility, the HCYY11112011 easily integrates with a variety of aerial work vehicles. Its user-friendly installation process means that operators can quickly set it up without extensive training. This compatibility ensures that businesses can adapt their equipment to meet specific requirements with minimal downtime.

These features collectively make the HCYY11112011 Folding Boom Angle Cylinder a reliable and efficient choice for any aerial work application, enhancing productivity and safety on the job.

How Do You Prioritize Safety And Efficiency In Your Aerial Work Operations?

Certainly! Here’s an expanded and optimized version of the strategies for prioritizing safety and efficiency in aerial work operations:

1. Regular Training

Implementing a comprehensive training program is crucial for fostering a culture of safety. Regular training sessions should cover equipment operation, safety protocols, and emergency procedures. Incorporating hands-on drills and simulations can help workers gain practical experience. Additionally, refresher courses should be scheduled to keep skills sharp and ensure that all personnel are updated on the latest safety regulations and best practices.

2. Routine Inspections

Conducting thorough and frequent inspections of all equipment, including the HCYY11112011 Folding Boom Angle Cylinder, is essential for maintaining operational safety. Develop a systematic inspection checklist that includes checks for wear and tear, hydraulic leaks, and functionality of safety features. Documenting these inspections helps track the condition of equipment over time and ensures that any potential issues are addressed proactively before they lead to accidents or equipment failure.

3. Safety Equipment

Providing workers with the appropriate personal protective equipment (PPE) is vital for minimizing risks. This includes hard hats, harnesses, gloves, and eye protection tailored to the specific tasks at hand. Additionally, ensure that all safety features on machinery—such as emergency stop buttons and safety guards—are regularly tested and maintained. Promoting the use of PPE through training and reminders reinforces its importance in protecting workers from potential hazards.

4. Clear Communication

Establishing effective communication among team members is paramount, especially during operations that require coordination. Utilize two-way radios, hand signals, or visual aids to ensure everyone is aware of their roles and responsibilities. Regular briefings before tasks begin can help clarify objectives and address any concerns. Encouraging an open dialogue allows team members to voice safety concerns and suggestions, fostering a collaborative environment focused on safety.

5. Risk Assessment

Performing thorough risk assessments prior to starting any job is essential for identifying potential hazards. Involve team members in this process to gain diverse perspectives on risks associated with specific tasks. Develop a risk mitigation plan that outlines the steps to minimize identified hazards, including implementing safety barriers, adjusting work schedules, or using alternative methods. Regularly reviewing and updating risk assessments ensures that safety measures remain relevant and effective.

6. Efficient Planning

Meticulous planning is key to optimizing both safety and efficiency in aerial work operations. Create detailed project plans that outline the scope of work, timelines, and resource allocation. Incorporate contingency plans for unexpected challenges, ensuring that the team is prepared to adapt as needed. By streamlining workflows and minimizing downtime, operations can run smoothly, allowing teams to focus on completing tasks safely and effectively.

By implementing these expanded strategies, you can significantly enhance safety and efficiency in your aerial work operations, ultimately leading to a more productive and secure work environment.

Aerial Work Vehicles Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: