HCYY11112005 Main Boom Angle Cylinder For Aerial Work Vehicles

Jako jeden z výrobců, dodavatelů a vývozců hydraulických válců nabízíme hydraulické válce a mnoho dalších výrobků.

Kontaktujte nás, prosím, pro podrobnosti.

Mail:sales@hydraulic-cylinders.net

Výrobce, dodavatel a vývozce hydraulických válců.

HCYY11112005 Main Boom Angle Cylinder For Aerial Work Vehicles

The HCYY11112005 Main Boom Angle Cylinder is an essential component designed specifically for aerial work vehicles. This cylinder plays a crucial role in accurately adjusting the angle of the main boom, allowing operators to reach desired heights and positions with precision and stability. Its reliable performance enhances the efficiency and safety of aerial operations significantly.

As a fundamental part of aerial work vehicles, the HCYY11112005 provides the necessary durability and accuracy for effective and secure use. Its robust construction, easy installation, and compatibility with a variety of models make it a preferred choice among fleet operators. By ensuring proper maintenance of this vital component, operators can optimize the performance of their aerial work vehicles, leading to improved productivity and safety on job sites. Investing in the HCYY11112005 not only elevates your aerial operations but also guarantees outstanding results.

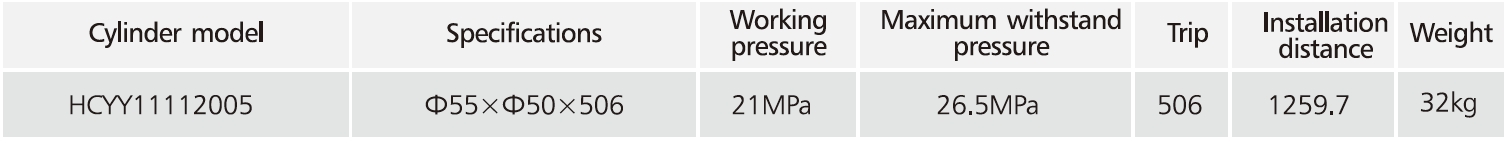

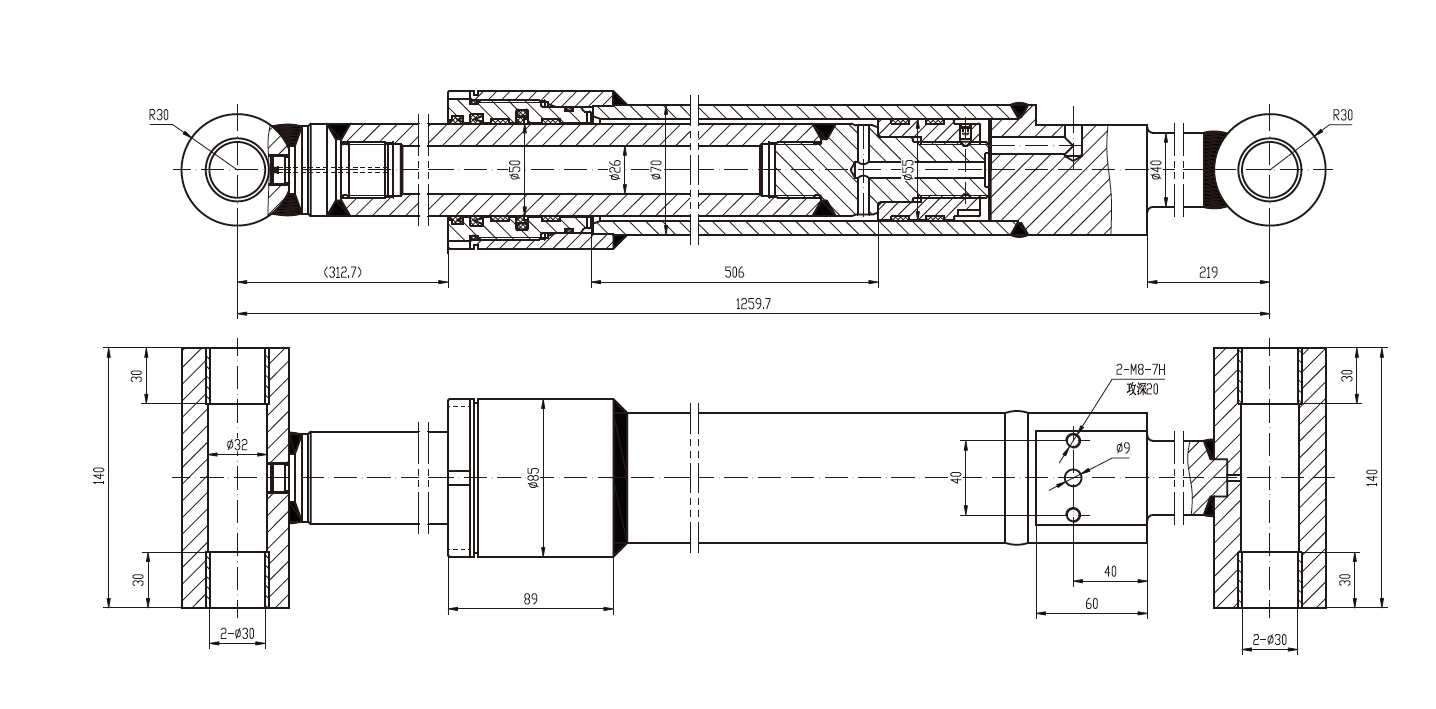

HCYY11112005 Main Boom Angle Cylinder For Aerial Work Vehicles Parameter:

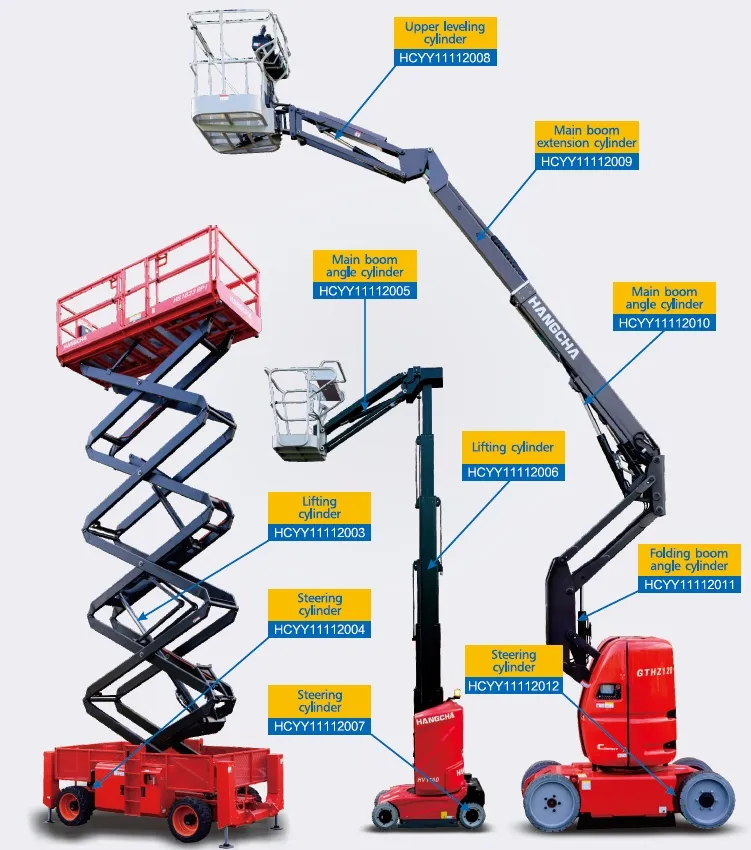

Cylinder Series For Aerial Work Vehicles:

Key Features of HCYY11112005 Main Boom Angle Cylinder For Aerial Work Vehicles:

Exceptional Durability

The HCYY11112005 Main Boom Angle Cylinder is constructed from high-quality materials designed to withstand extreme environmental conditions, including high humidity, temperature variations, and exposure to harsh chemicals. This robust build ensures the cylinder can endure heavy use in challenging work environments, significantly extending its operational lifespan. Operators benefit from this durability by experiencing fewer replacements and repairs, leading to lower overall operational costs.

Precision Adjustment

Meticulously engineered for accuracy, the HCYY11112005 allows for precise angle adjustments of the main boom. This level of control is essential for operators navigating confined or complex spaces where precision is critical. The cylinder’s design promotes smooth and responsive movements, enabling operators to position the boom exactly where needed. Such accuracy not only boosts operational efficiency but also enhances worker safety by ensuring reliable equipment performance.

Protective Coating

Featuring a specialized corrosion-resistant coating, the HCYY11112005 safeguards against rust and wear that can degrade performance over time. This protective layer minimizes maintenance needs, allowing operators to concentrate on their tasks without the burden of frequent upkeep. By addressing corrosion risks, this feature ensures the cylinder retains its functionality and visual appeal throughout its service life, contributing to long-term reliability.

Simplified Installation

The HCYY11112005 is designed for easy installation, facilitating quick integration into various aerial work vehicles. This user-friendly characteristic significantly reduces downtime during upgrades or replacements, enabling operators to swiftly return to work and maintain high productivity levels. Additionally, the straightforward installation process requires less specialized labor, further enhancing operational efficiency.

Broad Compatibility

This cylinder is engineered to be compatible with a diverse range of aerial work vehicle models, providing fleet operators with the flexibility to standardize components across their equipment. Such versatility simplifies inventory management, allowing operators to maintain fewer parts while still ensuring their vehicles are equipped with top-quality components. Standardization also aids in training operators and maintenance staff, as familiarity with a single type of cylinder fosters consistency and safety throughout the fleet.

In conclusion, the HCYY11112005 Main Boom Angle Cylinder excels in durability, precision, protective features, ease of installation, and compatibility, making it an indispensable component for any aerial work vehicle.

How Does The HCYY11112005 Main Boom Angle Cylinder Enhance The Safety And Efficiency Of Aerial Work Operations?

Certainly! Here’s an expanded and optimized response regarding the specific environments the HCYY11112005 Main Boom Angle Cylinder is designed to withstand:

1. High Humidity

The HCYY11112005 Main Boom Angle Cylinder is engineered to perform reliably in high-humidity environments, where excess moisture can lead to corrosion and degradation of equipment. Its advanced materials and protective coatings prevent rust, ensuring that the cylinder maintains its functionality even in damp conditions. This capability is essential for operations conducted in coastal areas, rainy climates, or locations where humidity levels are consistently elevated, allowing operators to work confidently without worrying about equipment failure.

2. Temperature Fluctuations

Designed to endure a wide range of temperature variations, the HCYY11112005 functions effectively in both extreme heat and cold. This resilience is crucial for aerial work vehicles operating in diverse climates, from scorching summers to frigid winters. The cylinder’s construction ensures that it remains operational and maintains performance standards, regardless of the temperature challenges it faces. This versatility enables operators to use the equipment in various geographical locations without compromising safety or efficiency.

3. Harsh Chemicals

The HCYY11112005 is built with materials that withstand exposure to harsh chemicals frequently encountered in industrial and construction settings. Whether it’s solvents, fuels, or other corrosive substances, this cylinder’s robust design protects it from chemical damage, ensuring a longer service life. This resistance not only enhances the cylinder’s durability but also reduces the need for frequent replacements, allowing operators to focus on their tasks without the constant worry of equipment deterioration.

In summary, the HCYY11112005 Main Boom Angle Cylinder is specifically designed to excel in high-humidity conditions, withstand temperature fluctuations, and resist damage from harsh chemicals, making it an ideal choice for a variety of challenging work environments.

Aerial Work Vehicles Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: