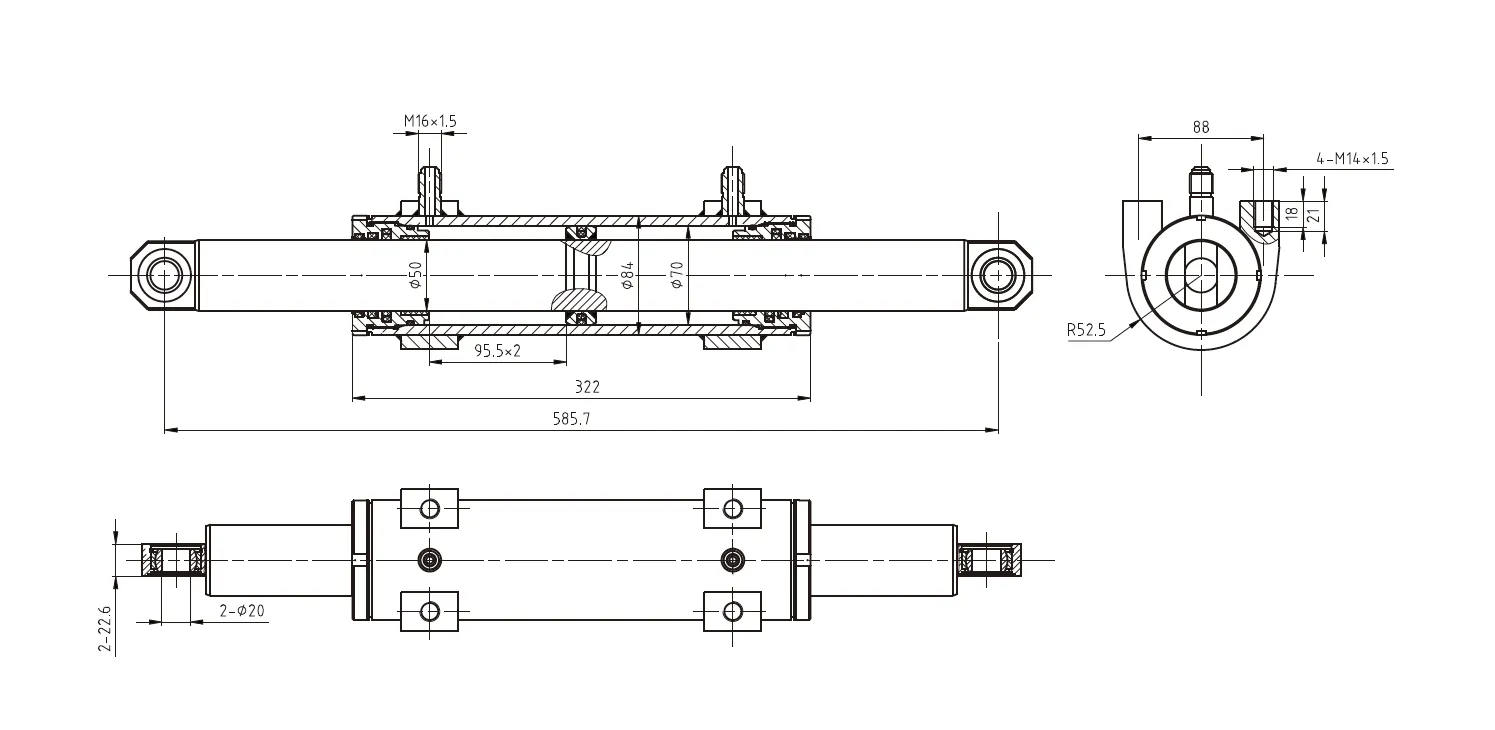

HCYY11112002 Forklift Steering Cylinder

Jako jeden z výrobců, dodavatelů a vývozců hydraulických válců nabízíme hydraulické válce a mnoho dalších výrobků.

Kontaktujte nás, prosím, pro podrobnosti.

Mail:sales@hydraulic-cylinders.net

Výrobce, dodavatel a vývozce hydraulických válců.

HCYY11112002 Forklift Steering Cylinder

The HCYY11112002 Forklift Steering Cylinder stands as a vital component that significantly boosts the maneuverability and control of forklifts across diverse operational environments. Crafted for both efficiency and reliability, this steering cylinder empowers operators to navigate tight spaces and manage heavy loads effortlessly.

As an essential part of any forklift operation, the HCYY11112002 offers robust construction, exceptional responsiveness, and easy maintenance, making it an ideal choice for businesses aiming to enhance their material handling capabilities. By adhering to proper usage and maintenance practices, you can ensure the steering cylinder operates smoothly and efficiently, leading to safer and more effective operations.

Investing in high-quality components like the HCYY11112002 not only elevates productivity but also enhances the overall safety of your workforce. Experience the difference that reliable steering can make and transform your operational efficiency today!

HCYY11112002 Forklift Steering Cylinder Parameter:

Forklift Cylinder Series:

Key Features of the HCYY11112002 Forklift Steering Cylinder:

- Durable Construction: Crafted from premium-grade materials, the HCYY11112002 is built to endure the demands of heavy-duty operations and harsh working conditions. Its robust design ensures exceptional longevity and reliability, minimizing the need for frequent replacements.

- High Responsiveness: Experience unparalleled control with this steering cylinder, which delivers quick and precise steering responses. Operators can navigate tight corners and complex layouts effortlessly, resulting in smoother turns and improved handling of loads. This responsiveness not only enhances efficiency but also boosts overall safety.

- Corrosion Resistance: The HCYY11112002 features specially treated surfaces that resist rust and deterioration. This corrosion-resistant property extends the cylinder’s lifespan and maintains optimal performance, even in environments exposed to moisture or harsh chemicals.

- Easy Installation: Designed with user convenience, the HCYY11112002 allows for straightforward installation. Its intuitive setup process minimizes downtime, enabling quick replacements and repairs. This feature means less disruption to your operations and more time for productivity.

- Broad Compatibility: Versatility is a hallmark of the HCYY11112002. Engineered to fit various forklift models, this steering cylinder adapts seamlessly to different systems, making it an ideal choice for diverse businesses. Whether you operate a single type of forklift or a fleet, this component meets your varied needs with ease.

- Enhanced Safety Features: Incorporating advanced safety mechanisms, the HCYY11112002 ensures stable operation under various conditions. This added layer of safety protects both operators and loads, further enhancing the overall workplace environment.

- Low Maintenance Requirements: Designed for durability and efficiency, the HCYY11112002 requires minimal maintenance. Regular checks and occasional lubrication keep it performing at its best, allowing your team to focus on their tasks without worrying about frequent servicing.

By choosing the HCYY11112002 Forklift Steering Cylinder, you invest in a product that enhances operational efficiency and contributes to a safer, more productive workplace. Experience the difference these advanced features can make in your material handling operations!

What Are The Signs That A Forklift Steering Cylinder Needs Replacement?

A well-functioning steering cylinder is crucial for the safe operation of your forklift. Here are some telltale signs that it may be time for a replacement:

- Hydraulic Fluid Leaks

If you notice puddles of hydraulic fluid beneath your forklift, it’s a red flag. Leaks indicate that the seals within the steering cylinder may be worn or damaged, compromising the system’s integrity. - Steering Difficulties

Struggling to turn the steering wheel or feeling a hefty resistance can signal underlying issues. A responsive steering system is essential for efficiency and safety, so don’t ignore these symptoms. - Unusual Noises

Pay attention to any grinding, squeaking, or clunking sounds during operation. These noises can indicate mechanical wear or misalignment within the steering cylinder, which could lead to more severe problems if left unaddressed. - Worn Seals and Bushings

Regularly inspect the seals and bushings for signs of wear. Cracks or fraying can lead to leaks and reduced performance, making timely replacement critical. - Inconsistent Movement

If your forklift’s steering feels jerky or unsteady, it may indicate hydraulic issues within the cylinder. Smooth steering is vital for precise maneuvering, especially in tight spaces. - Excessive Play

A noticeable increase in play or looseness in the steering wheel can indicate that the steering cylinder is failing. This can affect your control and increase the risk of accidents. - Warning Lights

Many modern forklifts have diagnostic systems that alert you to potential issues. If you see a warning light related to steering, take it seriously and investigate promptly.

Being proactive about these signs can save you from costly repairs and unsafe operating conditions. Regular maintenance and timely replacements ensure your forklift remains reliable and efficient. If you notice any of these symptoms, consult with a professional to assess the situation and consider replacing your steering cylinder for optimal performance. Your safety and productivity depend on it!

Forklift Cylinder Production Area:

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line with a designed annual production capacity of million pieces. The special cylinder workshop has semi-automatic cleaning and assembly systems of various specifications with a designed annual production capacity of 200000 pieces. It is equipped with famous brand CNC machining equipment, machining centers, special equipment for high-precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of key equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

The machining shop is equipped with custom-made tilt guiderailturning centers, machining centers, high-speed honing machines, welding robots, and other relevant equipment, which can handle the machining work of cylinder tubes with 400mm Max ID and 6 meters of Max length.

We have a fully automatic water-based paint coating line for small and medium cylinders, which realizes automatic loading and unloading and automatic spraying robots with a designed production capacity of 4000 places per shift. We have another semi-automatic painting line for large-scale cylinders driven by a power chain, and the design capacity is 60 crates per shift.

To further improve product performance and establish the leadership position of our hydraulic cylinders in the industry, our company and zjimee jointly established a Comprehensive performance laboratory of hydraulic cylinders, hydraulic valves, and hydraulic pumps; the lab is computer-assisted testing using electro-hydraulic technology, the test conditions are preset by a computer which improves the test accuracy and system versatility, and the experimental data.

The automatic collection is realized through the application of sensors, and the output data, such as the internal leakage and load efficiency of the cylinder or the vale, are directly processed by the computer and converted to standard units (ml/min%). At the same time, to ensure the working safety of the hydraulic system, the state monitoring function is carried out for key performance parameters such as”oil temperature monitoring, liquid level monitoring, filter device monitoring,” etc. Among them, the hydraulic cylinder test stand can test the performance of the “load

efficiency “and” internal leakage” by readings. At the same time, it is equipped with a grating ruler measuring instrument that meets the requirements of all test items of hydraulic cylinder products according to the national standard.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: