Aerial Work Platform Telescopic Cylinder

Jako jeden z výrobců, dodavatelů a vývozců hydraulických válců nabízíme hydraulické válce a mnoho dalších výrobků.

Kontaktujte nás, prosím, pro podrobnosti.

Mail:sales@hydraulic-cylinders.net

Výrobce, dodavatel a vývozce hydraulických válců.

Aerial Work Platform Telescopic Cylinder

The aerial work platform telescopic cylinder is a powerful and essential component in aerial work platforms, designed to provide extended reach and enhanced versatility in elevated work environments. This innovative hydraulic cylinder enables the telescopic movement of the platform, allowing operators to access elevated areas with ease and precision.

The aerial work platform telescopic cylinder is a powerful and essential component in aerial work platforms, designed to provide extended reach and enhanced versatility in elevated work environments. This innovative hydraulic cylinder enables the telescopic movement of the platform, allowing operators to access elevated areas with ease and precision.

The aerial work platform telescopic cylinder is a game-changer in the realm of elevated work platforms, providing extended reach and enhanced versatility. With its remarkable characteristics, including extended reach capability, smooth telescopic movement, high load capacity, and compact design, this cylinder empowers operators to tackle elevated tasks efficiently and confidently. By following the recommended usage methods and maintenance practices, operators can maximize the lifespan and performance of the aerial work platform telescopic cylinder, resulting in increased productivity, reduced downtime, and enhanced safety in elevated work applications. Invest in this cutting-edge hydraulic component to elevate your aerial work platform’s capabilities and take your elevated work to new heights of success.

Aerial Work Platform Telescopic Cylinder Key Characteristics:

- Extended Reach Capability:

- The aerial work platform telescopic cylinder boasts an impressive extendable range, enabling operators to reach greater heights and distances effortlessly.

- It provides flexibility and adaptability, allowing workers to access challenging areas and complete tasks efficiently.

- Smooth Telescopic Movement:

- This cylinder ensures smooth and controlled telescopic movement, allowing for precise positioning of the aerial work platform.

- It offers stable and steady extension and retraction actions, ensuring a safe and secure working environment at various heights.

- High Load Capacity:

- The aerial work platform telescopic cylinder is designed to handle heavy loads and has a robust construction that can support considerable payloads.

- It enables operators to carry multiple workers, tools, and equipment on the platform without compromising stability or safety.

- Compact Design:

- With its compact design, this cylinder optimizes the space on the aerial work platform, ensuring minimal impact on the overall weight and footprint.

- The compactness of the cylinder allows for excellent maneuverability and ease of transportation.

Aerial Work Platform Telescopic Cylinder Parameter:

| Product Name | Aerial Work Platform Telescopic Cylinder |

| Features: | Realize the linear telescopic movement of the boom |

| Bore diameter: | 45mm~200mm |

| Rod diameter: | 32mm~180mm Stroke≤15000mm |

| Pressure: | 30MPa(Maximum pressure |

| Telescopic Cylinder Applications: | Aerial Work Platform |

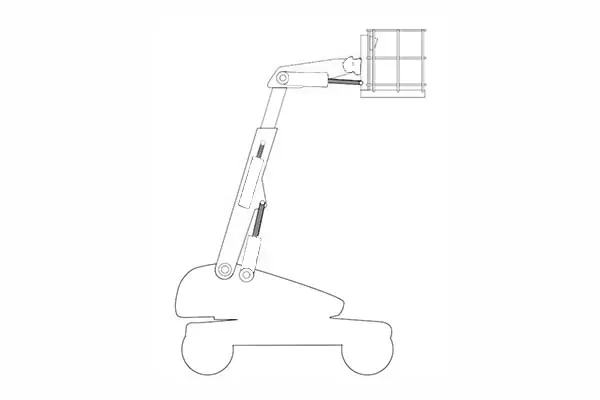

Aerial Work Platform Identification Diagram:

Usage Method Of Aerial Work Platform Telescopic Cylinder:

- Cylinder Installation:

- Follow the manufacturer’s instructions for properly installing the aerial work platform luffing cylinder.

- Ensure the cylinder is securely mounted to the aerial work platform’s structure, providing a stable and reliable connection.

- Hydraulic Connection:

- Connect the cylinder to the hydraulic system of the aerial work platform according to the provided guidelines.

- Ensure that all hydraulic connections are secure and properly sealed to prevent any leaks or loss of hydraulic fluid.

- Control Activation:

- Utilize the platform’s control panel or interface to activate the aerial work platform luffing cylinder.

- Follow the recommended operating procedures to lift or lower the platform to the desired height.

- Safety Precautions:

- Before operating the aerial work platform, familiarize yourself with the safety features and emergency procedures.

- Ensure that all operators receive proper training on the safe operation of the platform and the aerial work platform luffing cylinder.

What Law Of Hydraulics Does The Brake System Use?

The brake system in vehicles typically utilizes Pascal’s law of hydraulics. Pascal’s law states that when pressure is applied to a fluid in an enclosed system, the pressure is transmitted equally in all directions.

In the case of a hydraulic brake system, when the brake pedal is depressed, it applies force to a master cylinder, which contains hydraulic fluid. The force exerted on the fluid creates pressure, transmitted equally throughout the brake system.

This pressure is then transmitted to the brake calipers or wheel cylinders, depending on the type of brake system, located at each wheel. The pressure causes the calipers or cylinders to actuate, which in turn applies the brake pads or shoes against the brake rotors or drums, creating friction and slowing down or stopping the vehicle.

Pascal’s law ensures that the force applied at the brake pedal is multiplied and transmitted equally to all the brakes in the system, regardless of their location. This allows for consistent braking performance across all wheels and ensures effective braking even in complex hydraulic brake systems.

It’s worth noting that in some advanced brake systems, additional principles of hydraulics, such as Bernoulli’s principle or the principle of fluid dynamics, may also be employed to optimize braking performance, stability, and control. However, Pascal’s law remains fundamental to the basic operation of hydraulic brake systems.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: