Aerial Work Platform Electric Cylinder

Jako jeden z výrobců, dodavatelů a vývozců hydraulických válců nabízíme hydraulické válce a mnoho dalších výrobků.

Kontaktujte nás, prosím, pro podrobnosti.

Mail:sales@hydraulic-cylinders.net

Výrobce, dodavatel a vývozce hydraulických válců.

Aerial Work Platform Electric Cylinder

The aerial work platform electric cylinder is a cutting-edge hydraulic component designed to enhance efficiency and safety in elevated work environments. This innovative cylinder is critical in aerial work platforms, providing precise and controlled vertical movement for workers, tools, and equipment.

With the increasingly strict environmental protection laws and regulations, people’s environmental awareness is gradually increasing, and the requirements for construction machinery are growing. With its low noise and other advantages, the electric cylinder with no leakage, high efficiency, and low pollution just makes up for this need. All kinds of construction machinery or manipulators with electric cylinders as mechanical carriers have gradually become popular In many businesses.

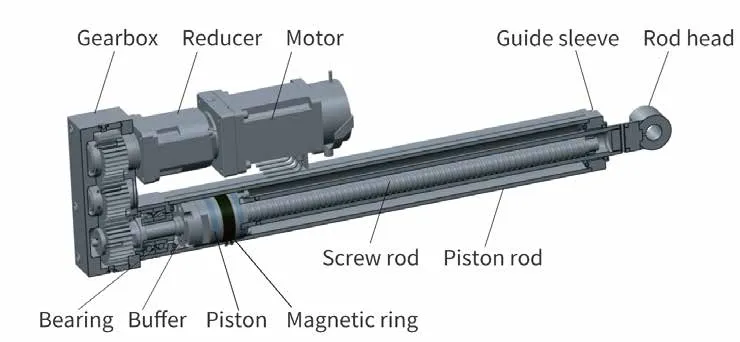

As a kind of electric actuator, the electric cylinder has the characteristics of low cost, compact structure, easy installation, high control precision, and flexible operation. As a mechanical motion carrier, the electric cylinder drives the ball screw movement through the rotation of the servo motor, so that the angular displacement is transformed into a linear displacement, to achieve accurate speed control, position control, and thrust control.

The electric cylinder has the advantages of high efficiency, large carrying capacity, fast speed, precise and controllable movement, etc. It is widely used in aerospace tests, multi-degree of freedom simulation, multi-degree of freedom dynamic entertainment, multi-degree of freedom precision machining, robot, automobile manufacturing and other fields of equipment, steel connection casting, petrochemical, material handling, injection molding machines, mold control, valve control, precision machinery, pharmaceutical machinery, food processing, and other fields.

Aerial Work Platform Electric Cylinder Key Characteristics:

- Smooth and Precise Vertical Movement:

- The aerial work platform electric cylinder offers smooth and precise vertical movement, ensuring accurate positioning at desired heights.

- It allows operators to easily adjust the platform height, facilitating efficient work execution and enhanced productivity.

- Electric-Powered Performance:

- This cylinder operates on electric power, eliminating the need for manual pumping or external power sources.

- It offers quiet and efficient operation, making it suitable for indoor applications where noise and emissions must be minimized.

- High Load Capacity:

- The aerial work platform electric cylinder boasts a high load capacity, enabling it to easily support workers, tools, and heavy equipment.

- It is engineered to withstand demanding work environments and handle substantial loads without compromising safety or performance.

- Safety Features:

- This cylinder incorporates advanced safety features such as limit switches, emergency stop buttons, and overload protection.

- These safety mechanisms ensure operator safety by preventing excessive platform movement, overloading, or unintended operation.

Aerial Work Platform Electric Cylinder Parameter:

| Product Name | Aerial Work Platform Electric Cylinder |

| Features: | Realize telescopic function |

| Thrust force: | 1-1000KN |

| Voltage: | 24V,48V,220V,380V… |

| Electric Cylinder Features: | High efficiency, Fast speed, Heavy loading, High precision |

| Electric Cylinder Applications: | Scissor aerial work platform, Mast aerial work platform, Fire truck, Automatic production line, etc. |

Aerial Work Platform Identification Diagram:

Usage Method Of Aerial Work Platform Electric Cylinder:

- Platform Installation:

- Follow the manufacturer’s instructions for properly installing the aerial work platform electric cylinder.

- Ensure the cylinder is securely mounted to the aerial work platform’s frame, providing a stable and reliable connection.

- Electrical Connection:

- Connect the cylinder to the electrical power supply according to the provided guidelines.

- Ensure all electrical connections are secure and properly insulated to prevent electrical hazards.

- Platform Height Adjustment:

- Utilize the control panel or interface provided to adjust the platform height.

- Follow the recommended operating procedures and safety guidelines for smooth, controlled vertical movement.

- Safety Considerations:

- Before operating the aerial work platform, familiarize yourself with the safety features and emergency procedures.

- Ensure that all operators receive proper training on the safe operation of the platform and the aerial work platform electric cylinder.

Application Of Electric Cylinder:

How A Hydraulic System Works?

A hydraulic system is a mechanical power transmission system that utilizes the force of fluid to generate and transmit power. It operates based on Pascal’s law, which states that when pressure is applied to a confined fluid, the pressure is transmitted equally in all directions.

Here is a simplified explanation of how a hydraulic system works:

- Components of a Hydraulic System:

- Hydraulic Fluid: Typically oil-based, it is the medium for transmitting power.

- Hydraulic Pump: It generates fluid flow and creates pressure in the system.

- Hydraulic Cylinder: Converts fluid pressure into linear motion or force.

- Control Valves: Regulate the flow and direction of the hydraulic fluid.

- Hydraulic Motor: Converts fluid pressure into rotational motion.

- Pumping Fluid:

- The hydraulic pump draws in hydraulic fluid from a reservoir and delivers it under pressure to the rest of the system.

- As the pump operates, it creates a vacuum that pulls fluid into its inlet port.

- Fluid Distribution:

- The pressurized fluid flows through hydraulic lines or hoses to reach various components in the system.

- These lines are designed to withstand high-pressure conditions and transmit fluid without leakage.

- Control Valves:

- Control valves determine the hydraulic fluid’s flow direction, rate, and pressure.

- They are operated manually or electronically and are responsible for activating or deactivating specific hydraulic components.

- Hydraulic Cylinder:

- A hydraulic cylinder consists of a cylindrical tube, a piston, and a rod.

- When pressurized fluid enters one side of the cylinder, it pushes the piston, which moves the rod.

- This linear motion can lift, push, or move external loads.

- Hydraulic Motor:

- A hydraulic motor converts fluid pressure into rotational motion.

- It consists of a rotor and a stator, and the pressurized fluid causes the rotor to rotate.

- The rotational output can be used to drive machinery or perform work.

- Return and Filtration:

- After performing its intended function, the hydraulic fluid returns to the reservoir for reuse.

- Filtration systems ensure the fluid is clean and free from contaminants, preventing damage to the hydraulic components.

- Control and Safety:

- Hydraulic systems incorporate various control mechanisms, such as pressure relief valves, to prevent excessive pressure buildup and ensure system safety.

- Sensors and feedback devices may monitor and regulate system parameters like pressure, temperature, and flow.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: