0.75KW With Cooling Fan Standard Hydraulic Power Unit Pack

Jako jeden z výrobců, dodavatelů a vývozců hydraulických válců nabízíme hydraulické válce a mnoho dalších výrobků.

Kontaktujte nás, prosím, pro podrobnosti.

Mail:sales@hydraulic-cylinders.net

Výrobce, dodavatel a vývozce hydraulických válců.

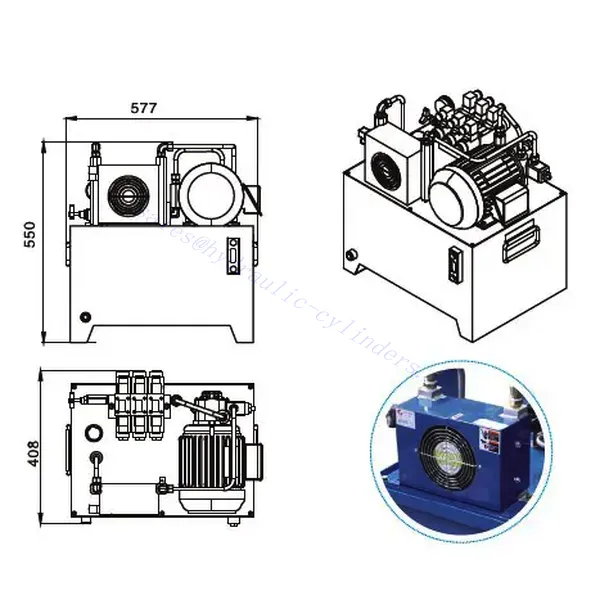

0.75KW With Cooling Fan Standard Hydraulic Power Unit Pack

The 0.75KW With Cooling Fan Standard Hydraulic Power Unit Pack is a reliable and efficient hydraulic power unit designed to provide optimal hydraulic power for a variety of industrial applications. With its powerful performance, built-in cooling fan, and standard configuration, this power unit offers exceptional functionality and versatility in hydraulic systems that require consistent power delivery and effective cooling. Whether used in machine tools, material handling equipment, or other hydraulic-powered machinery, the 0.75KW With Cooling Fan Standard Hydraulic Power Unit Pack ensures reliable operation and enhanced productivity.

Standard Hydraulic Power Unit Packs Model Description:

0.75KW Without Cooling Fan Standard Hydraulic Power Unit Pack Parameter:

Standard Hydraulic Power Unit Packs Specification:

Standard Hydraulic Power Unit Packs Optional Parts:

Standard Hydraulic Power Unit Packs Schematic diagram:

Key Characteristics and Benefits Of Standard Hydraulic Power Unit Packs:

- Powerful Performance:

- 0.75KW with cooling fan The standard hydraulic power unit package is rated at 0.75KW and provides plenty of power for a wide range of hydraulic applications.

- Its powerful performance ensures efficient and reliable operation, making the hydraulic machinery run smoothly.

- Built-in Cooling Fan:

- This power unit has a built-in cooling fan that helps dissipate the heat generated during operation.

- Cooling fans can effectively reduce the operating temperature of the power supply unit, prevent overheating, and ensure optimal performance even if used for a long time.

- Standard Configuration:

- 0.75KW Standard Hydraulic power unit package with cooling fan comes in standard configuration and includes the necessary hydraulic components such as motor, pump, reservoir, and control valve.

- The standard configuration simplifies installation, replacement, and compatibility with existing hydraulic systems, reducing complexity and downtime.

How To Disassemble Hydraulic Cylinder?

To disassemble a hydraulic cylinder, follow these general steps:

- Safety Precautions:

- Before starting, ensure the hydraulic system is depressurized and the power source is disconnected.

- Use appropriate personal protective equipment, such as gloves and safety goggles, to protect yourself from any potential hazards.

- Positioning and Support:

- Place the hydraulic cylinder on a stable work surface, ensuring it is adequately supported to prevent accidental movement or damage.

- Remove External Components:

- Disconnect any external components attached to the cylinder, such as hoses, fittings, or mounting brackets.

- Use suitable tools, such as wrenches or pliers, to loosen and remove these components carefully.

- Drain Hydraulic Fluid:

- Locate the drain plug or valve on the cylinder and remove it to allow the hydraulic fluid to drain into a suitable container.

- Position the cylinder in a way that facilitates complete drainage.

- Disassemble End Caps:

- Identify the end caps of the hydraulic cylinder. They are usually located at each end of the cylinder barrel.

- Remove bolts, screws, or fasteners, securing the end caps using the appropriate tools.

- If necessary, gently tap the end caps with a rubber mallet to break any seal or adhesive bond.

- Separate Cylinder Components:

- With the end caps removed, carefully slide out the piston and piston rod from the cylinder barrel.

- Please pay attention to any seals, bearings, or bushings present and remove them as necessary.

- Take note of the order and orientation of the components for easier reassembly.

- Inspect and Clean Components:

- Inspect each disassembled component for signs of wear, damage, or contamination.

- Clean all components using an appropriate solvent or cleaner to remove dirt, debris, or old lubricant.

- Use a soft cloth or brush to gently clean the surfaces without causing any damage.

- Replace or Repair Components:

- If any components show significant wear or damage, consider replacing them with new ones.

- Repair or rebuild components, such as replacing seals or reconditioning the piston rod.

- Reassembly:

- Follow the reverse order of disassembly to reassemble the hydraulic cylinder, ensuring proper alignment and orientation of components.

- Lubricate the appropriate parts with recommended hydraulic fluid or lubricant during reassembly.

- Tighten all fasteners to the manufacturer’s specifications, using a torque wrench if necessary.

- Testing and Inspection:

- Once reassembled, conduct a thorough inspection to ensure all components are correctly aligned and secured.

- Test the hydraulic cylinder in a controlled manner to verify its functionality and check for any leaks or abnormal operation.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic power unit pack manufacturers. We can offer comprehensive hydraulic power unit pack stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: