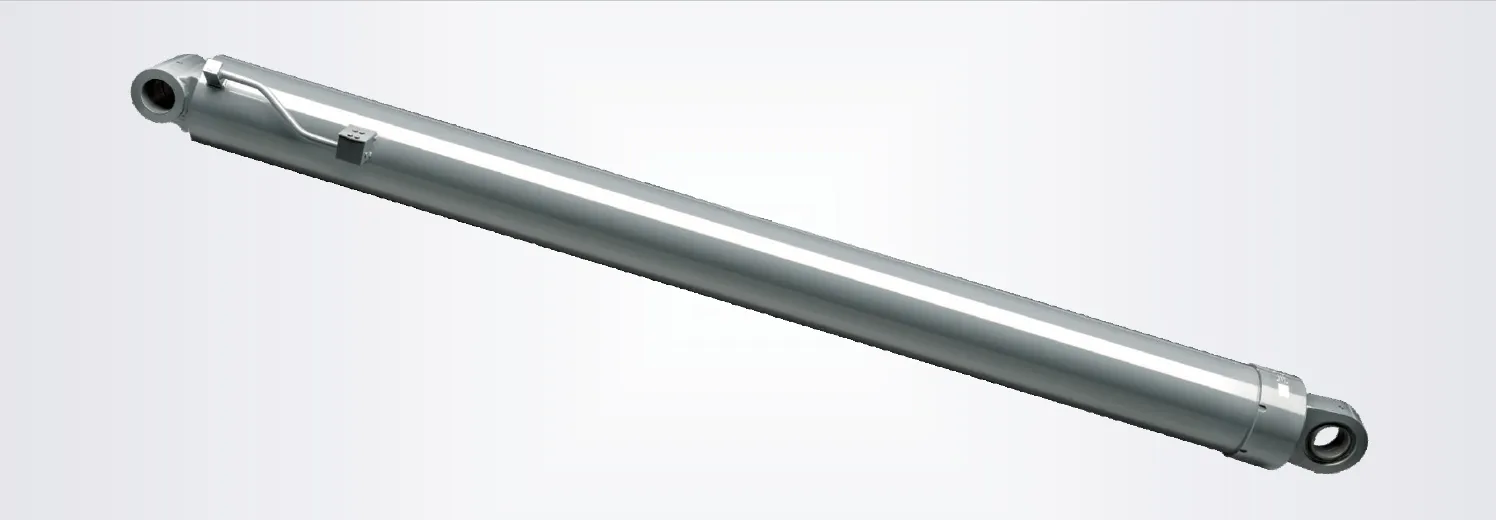

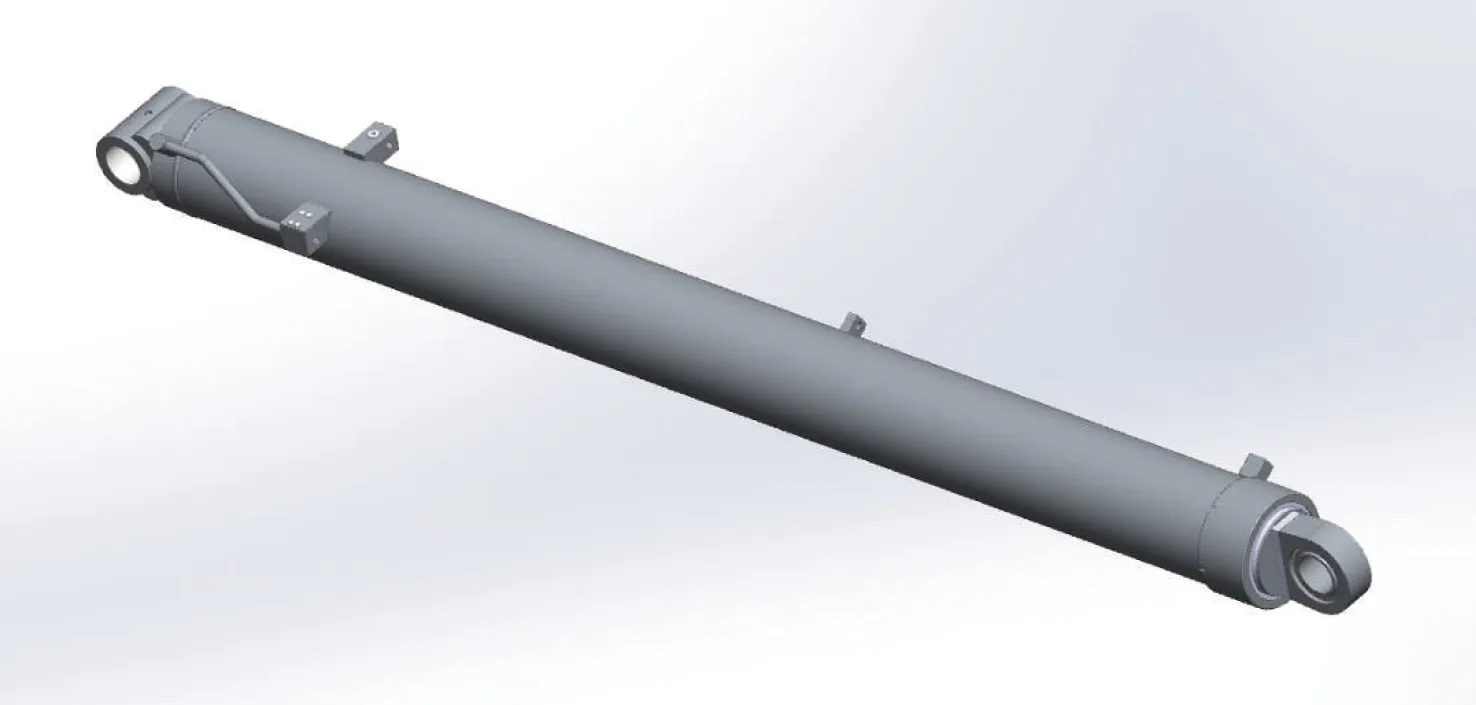

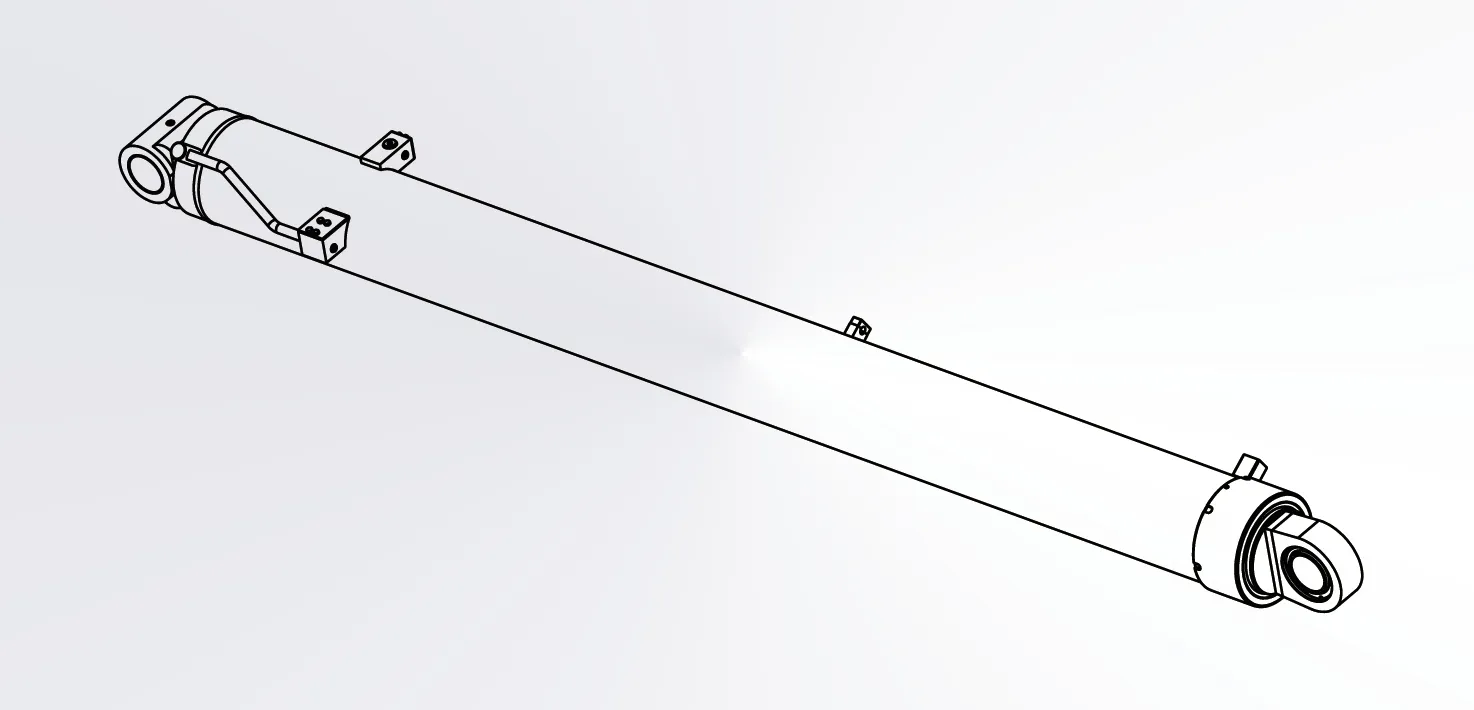

HCYY11112021 Main Boom Angle Cylinder For Truck Cranes

Като един от производителите, доставчиците и износителите на хидравлични цилиндри, ние предлагаме хидравлични цилиндри и много други продукти.

Моля, свържете се с нас за подробности.

Поща:sales@hydraulic-cylinders.net

Производител, доставчик и износител на хидравлични цилиндри.

HCYY11112021 Main Boom Angle Cylinder For Truck Cranes

The HCYY11112021 Main Boom Angle Cylinder is an essential component specifically designed for truck cranes, significantly enhancing their lifting capabilities and operational efficiency. This cylinder controls the angle of the main boom, ensuring precise maneuverability across a range of lifting tasks. Engineered to endure the demands of heavy-duty applications, the HCYY11112021 provides unmatched reliability and durability, making it a critical addition to any crane fleet.

Notably, the HCYY11112021 excels in performance and longevity within heavy lifting operations. With its impressive load capacity, robust construction, and precise engineering, this cylinder boosts both the efficiency and safety of crane operations. By adhering to proper usage and maintenance protocols, users can count on the HCYY11112021 to deliver consistent, reliable service for years. Investing in this vital component not only optimizes your truck crane’s capabilities but also ensures superior lifting performance in every task.

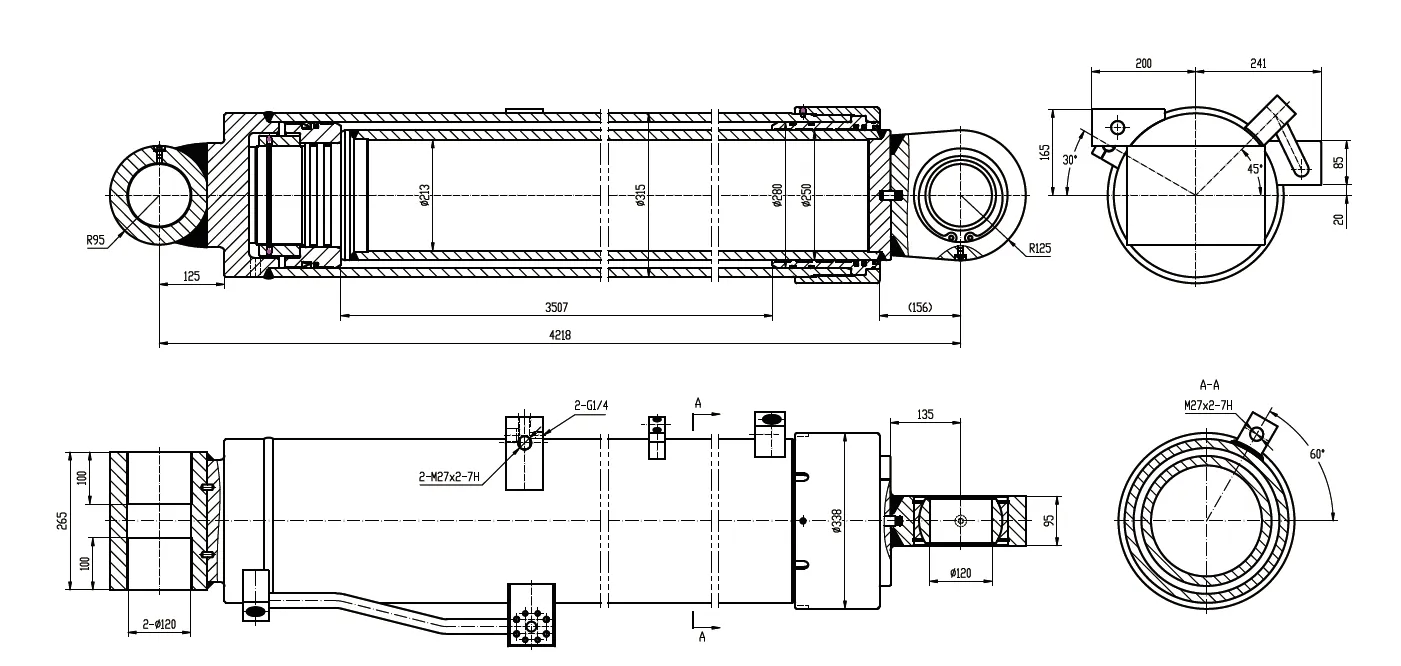

HCYY11112021 Main Boom Angle Cylinder For Truck Cranes Parameter:

Cylinder Series For Truck Cranes:

Key Features of HCYY11112021 Main Boom Angle Cylinder For Truck Cranes:

The HCYY11112021 Main Boom Angle Cylinder is an indispensable component specifically engineered for truck cranes, playing a pivotal role in significantly enhancing their lifting capabilities and operational efficiency. This advanced cylinder expertly controls the angle of the main boom, providing operators with precise maneuverability that is crucial for a wide variety of lifting tasks. Designed to withstand the rigorous demands of heavy-duty applications, the HCYY11112021 delivers unparalleled reliability and durability, making it a vital asset to any crane fleet.

Exceptional Performance

The HCYY11112021 shines in performance and longevity, particularly within demanding heavy lifting operations. Its impressive load capacity allows it to handle substantial weights with ease, ensuring that operators can tackle challenging jobs without hesitation. This robust construction not only enhances the cylinder’s strength but also reduces the risk of failures, thereby increasing safety during operation.

Precision Engineering

Engineered with meticulous attention to detail, the HCYY11112021 features advanced design elements that contribute to its overall efficiency. The precise engineering ensures smooth operation and accurate boom positioning, allowing for intricate maneuvers in tight spaces. This level of precision boosts both efficiency and safety, giving operators the confidence to perform complex lifts with precision.

Reliable Service

By adhering to recommended usage and maintenance protocols, users can count on the HCYY11112021 to provide consistent and reliable service for years. Regular inspections and proper care help maintain its performance, ensuring that it operates at its best when you need it most. This reliability translates to reduced downtime and increased productivity, making it a wise investment for any crane operation.

Optimal Investment

Investing in the HCYY11112021 is more than just adding a component to your crane; it’s about optimizing your entire lifting operation. This vital cylinder enhances the overall capabilities of your truck crane, empowering you to tackle a broader range of tasks with confidence. With superior lifting performance at your fingertips, you can take on projects that demand precision and strength, ultimately driving your success in the industry.

In summary, the HCYY11112021 Main Boom Angle Cylinder is not just a component—it’s a game-changer for truck crane operations. Its blend of exceptional performance, robust construction, and precise engineering makes it an essential element for achieving superior lifting results. With the right care, this cylinder will continue to serve you reliably, transforming your lifting capabilities and ensuring every task is executed with excellence.

How Does The Main Boom Angle Cylinder Enhance The Maneuverability Of Truck Cranes?

The Main Boom Angle Cylinder significantly enhances the maneuverability of truck cranes through several key mechanisms, each contributing to safer and more efficient operations.

1. Precise Boom Control

The cylinder allows operators to adjust the angle of the main boom with remarkable accuracy. This precision means that even the most intricate lifts can be executed with confidence, minimizing the risk of errors. Whether positioning a load in a crowded job site or maneuvering around obstacles, the ability to finely tune the boom angle ensures that every movement is deliberate and controlled.

2. Improved Range of Motion

By enabling a wider range of boom angles, the Main Boom Angle Cylinder expands the crane’s operational capabilities. This versatility is crucial when working in challenging environments, such as construction sites with overhead obstructions or tight spaces. Operators can easily reach elevated areas or navigate around barriers, making previously complex tasks more manageable and efficient.

3. Stability During Operation

One of the most critical aspects of crane operation is stability. The Main Boom Angle Cylinder helps maintain the crane’s balance while adjusting the boom, significantly reducing the risk of tipping. This stability is especially important when lifting heavy loads or working on uneven ground, as it ensures the safety of both the operator and the surrounding personnel.

4. Responsive Action

Quick adjustments to the boom angle lead to faster response times, allowing operators to adapt to changing job site conditions seamlessly. This responsiveness is vital in dynamic environments where conditions can shift rapidly. With the Main Boom Angle Cylinder, operators can react promptly, enhancing productivity and minimizing downtime.

5. Enhanced Visibility

Better control over the boom angle can significantly improve the operator’s line of sight. This clarity allows operators to maneuver loads with greater accuracy, ensuring that every lift is executed safely. Enhanced visibility not only boosts confidence but also fosters a safer work environment, as operators can better assess their surroundings while performing lifts.

In summary, the Main Boom Angle Cylinder is a transformative component for truck cranes, elevating their maneuverability and operational efficiency. With its ability to provide precise control, expand the range of motion, enhance stability, ensure responsive action, and improve visibility, this cylinder empowers operators to tackle even the most challenging lifting tasks with ease and confidence. Investing in this technology not only optimizes crane performance but also enhances overall safety and productivity on the job site.

Forklift Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: