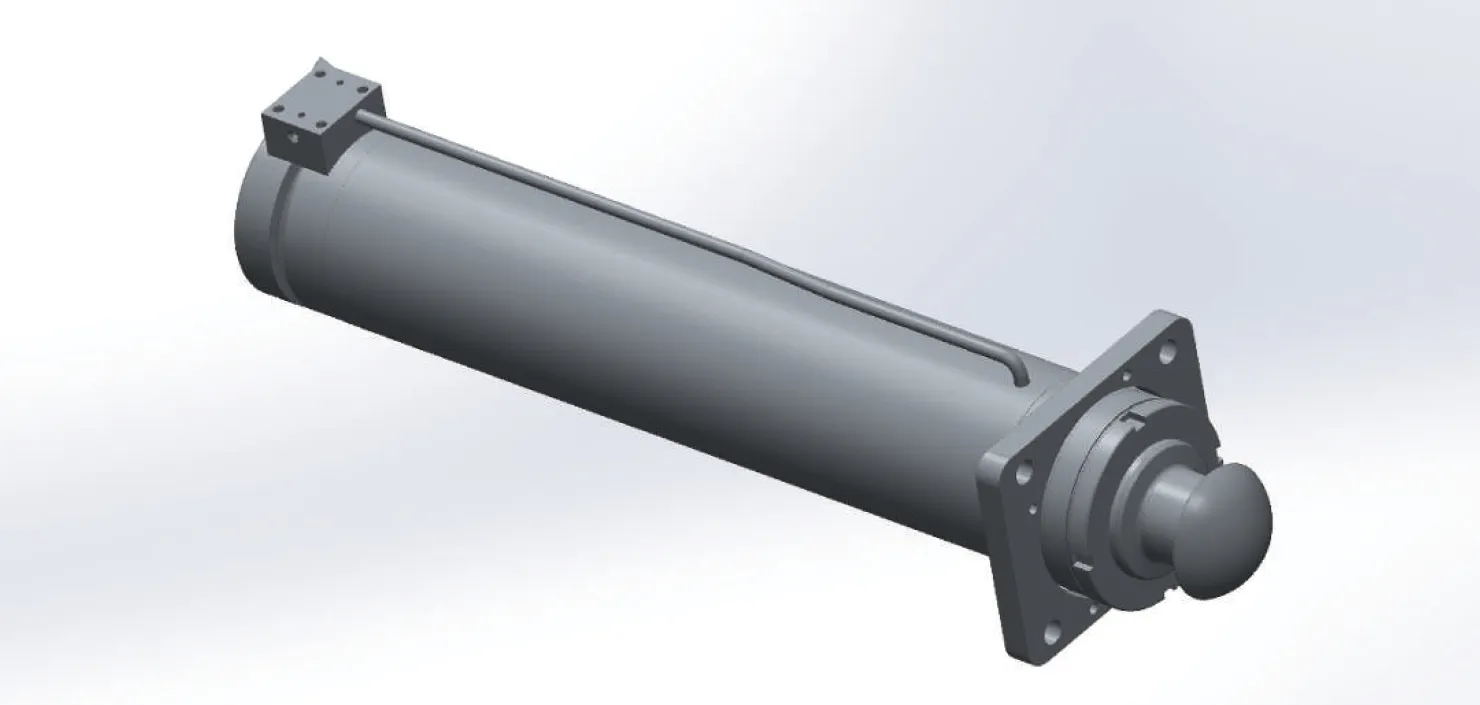

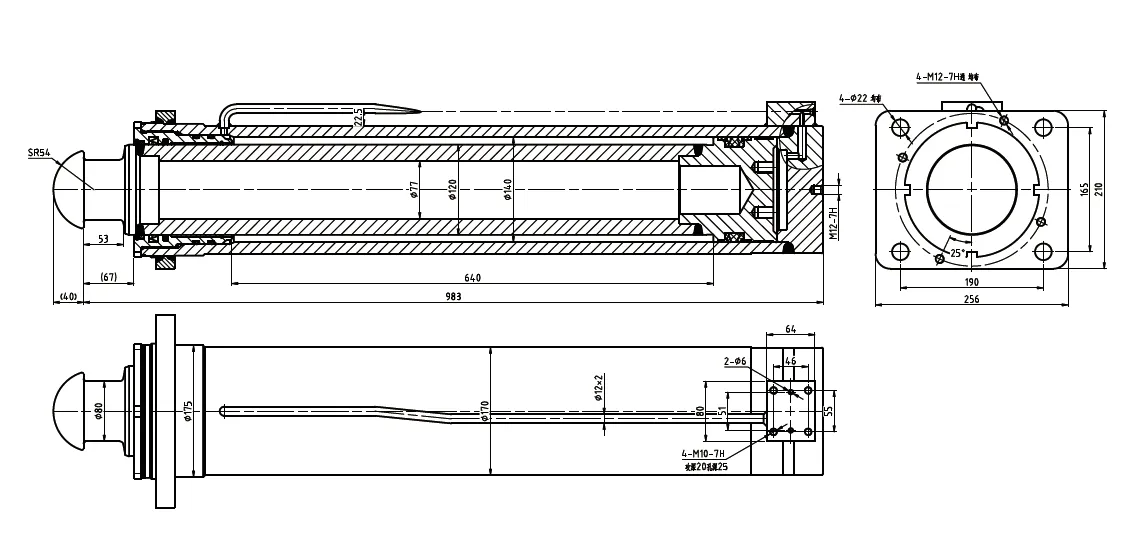

HCYY11112023 Cylinder For Frame Support For Truck Cranes

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

HCYY11112023 Cylinder For Frame Support For Truck Cranes

The HCYY11112023 Cylinder for Frame Support is vital for enhancing the stability and safety of truck cranes. Engineered for robust performance, this cylinder supports the crane’s frame during operations, ensuring it maintains structural integrity under various loads. Its reliability makes it an essential component for any fleet of cranes.

This cylinder stands out for its ability to provide stability and safety during lifting operations. Its durable design, straightforward installation, and low maintenance requirements make it a top choice for operators seeking both reliability and efficiency. By adhering to the recommended usage and maintenance practices, users can maximize the performance and lifespan of this crucial component, ensuring that their truck cranes operate smoothly and safely for years to come.

HCYY11112023 Cylinder For Frame Support For Truck Cranes Parameter:

Cylinder Series For Truck Cranes:

Key Features of HCYY11112023 Cylinder For Frame Support For Truck Cranes:

High Load Capacity

The HCYY11112023 Cylinder is engineered to handle significant weight, making it ideal for heavy lifting tasks. Its robust design allows it to bear the load without compromising safety or performance. Whether lifting construction materials, equipment, or other heavy objects, this cylinder ensures that operations run smoothly, providing peace of mind to operators and enhancing overall productivity.

Durable Construction

Constructed from high-quality materials, the HCYY11112023 Cylinder is built to withstand the rigors of demanding work environments. Its durable construction resists wear and tear, ensuring longevity even when exposed to extreme conditions. This resilience translates to fewer replacements and repairs, leading to cost savings and uninterrupted operations over time.

Corrosion Resistance

Equipped with a protective coating, the HCYY11112023 Cylinder effectively prevents rust and corrosion. This feature is crucial for maintaining performance and extending the lifespan of the cylinder, especially in harsh weather conditions or environments where moisture is prevalent. By resisting corrosion, the cylinder retains its structural integrity, ensuring reliable functionality throughout its life.

Easy Installation

The HCYY11112023 Cylinder is designed for straightforward integration into existing crane systems, which significantly minimizes downtime during installation. Its user-friendly design allows operators to quickly set it up without requiring extensive modifications or specialized tools. This ease of installation means that cranes can be back in operation swiftly, maximizing productivity and reducing delays in projects.

Precision Engineering

Manufactured with exact specifications, the HCYY11112023 Cylinder guarantees optimal performance and compatibility with various truck crane models. This precision engineering ensures that the cylinder operates efficiently and effectively, minimizing the risk of mechanical failures. By choosing this cylinder, operators can trust that they are utilizing a product designed to meet the highest standards of quality and reliability, enhancing overall operational efficiency.

How Does The Hcyy11112023 Cylinder Enhance The Stability Of Truck Cranes During Operation?

The HCYY11112023 Cylinder significantly enhances the stability of truck cranes during operation through several key mechanisms:

1. Weight Distribution

The cylinder plays a crucial role in distributing the load evenly across the crane’s frame. This balanced weight distribution is essential for preventing tipping, especially when lifting heavy or unevenly distributed loads. By ensuring that the center of gravity remains low and stable, the cylinder allows operators to perform complex maneuvers with confidence, knowing that the crane is secure and less likely to tip over. This feature not only enhances safety but also increases operational efficiency, allowing for more ambitious lifting tasks.

2. Robust Design

Engineered for high performance, the HCYY11112023 Cylinder boasts a robust design that can withstand substantial stress and strain. This durability means the cylinder can handle heavy lifting tasks without bending or breaking, which is vital for maintaining the crane’s stability during demanding operations. The cylinder’s ability to endure harsh conditions and heavy loads minimizes the risk of mechanical failures, ensuring that operations can continue smoothly. Operators benefit from reduced downtime and lower maintenance costs, making it a smart investment.

3. Resistance to Environmental Factors

The cylinder features advanced corrosion resistance, which is crucial for maintaining structural integrity in various weather conditions. By preventing rust and deterioration, the cylinder ensures that it remains reliable and effective, whether exposed to rain, snow, or extreme temperatures. This resilience is particularly important for cranes operating in challenging environments, as it guarantees consistent performance and safety. Operators can trust that their equipment will perform optimally, regardless of external factors, leading to increased confidence in their lifting operations.

4. Precision Engineering

Manufactured with meticulous attention to detail, the HCYY11112023 Cylinder is designed for exact compatibility with various truck crane models. This precision engineering ensures that the cylinder fits seamlessly into the crane’s system, reducing any play or movement that could compromise stability. A well-fitted cylinder minimizes the risk of instability caused by loose or misaligned components, allowing for smoother operations. This attention to detail enhances the overall performance of the crane, making it a reliable choice for operators who demand efficiency and safety.

5. Support During Movement

As truck cranes maneuver and adjust angles while lifting, the HCYY11112023 Cylinder provides continuous support, counteracting any forces that could lead to instability. This dynamic support is essential for safe lifting operations, particularly when navigating tight spaces or changing load positions. By offering consistent stability throughout the lifting process, the cylinder enables operators to execute complex tasks with precision and ease. This capability not only improves safety but also enhances productivity, allowing for faster completion of projects.

In summary, the HCYY11112023 Cylinder enhances truck crane stability through balanced weight distribution, robust design, environmental resistance, precision engineering, and dynamic support during movement. These features work together to ensure safe, efficient, and reliable operations, making it an indispensable component for any crane system.

Forklift Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: